16 tips on which airbrush to choose

Almost everyone knows what a spray gun is and why it is needed. And if some only occasionally face the problem of painting or whitewash premises during repair or construction, the work of professionals in various fields is already impossible to imagine without this unit. Painting, surface treatment, varnishing, applying a solution or a protective agent and many, many tasks can be easily solved with a spray gun. It remains only to figure out which airbrush to choose.

Principle of work and scope

The device is designed for uniform application and distribution on different surfaces primersmixtures, liquid rubber, enamel, paints and other materials. The main function of the spray gun - This is the splitting of liquid solutions for their finely dispersed spraying with a thin, even layer with a minimum number of smudges and bubbles.

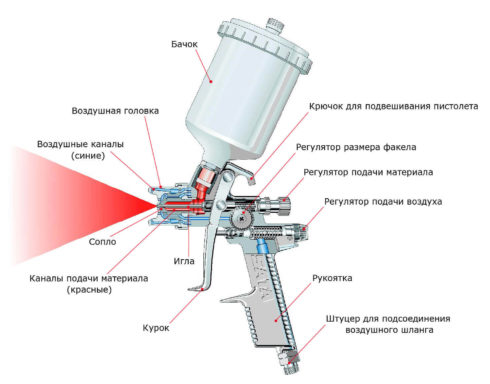

For more than a hundred years, namely, so much time has passed since the appearance of the spray gun, it has changed, modernized, become much more productive and more convenient. The principle of operation of spray guns (both electric and pneumatic) is the creation of a kind of aerosol from a liquid material in the form of tiny droplets, which is directed to the desired surface. Based on this, we can denote The main components of the devices:

- On / Off Spray Gun.

- Tank for paintwork materials.

- Paint and air supply pressure regulator.

- Air head and spray with nozzle (nozzle).

- Filter and nozzle for paint.

It is worth noting that in an electrical device paint is broken by a moving elastic membrane, and the pump is blown out by a pump (built-in). IN pneumatic equipment the driving force is a powerful stream of compressed air, which is pumped by the compressor and, falling into the spray gun, breaks up the liquid to the minimum possible particles.

In order to achieve the most uniform atomization, it is necessary to select and establish a balance of “material-air” in the optimal ratio. As a rule, the manufacturer indicates the input pressure parameters that are normal for a particular model of the device.

For the right choice of spray gun, it is important to know not only the principle of operation of the unit and its device, but also to have an idea of the scope and specific purpose of use. Knowing the exact object of painting - a car, door or ceiling - will greatly facilitate and narrow the search for the desired model.

There are two main types of appliances, electric and pneumatic, and You can use them for:

- Painting metal structures.

- Whitewash premises.

- Priming the walls.

- Painting ceilings and walls in buildings for various purposes.

- Fight bacteria and fungi by applying an antiseptic to the surface.

- Antigravel processing of metal parts.

- Simplification of works on cleaning walls from obsolete wallpapers.

- Painting car bodies and parts.

- Spraying green spaces from pests.

- Varnish, paint or stain coatings wooden surfaces.

- Staining of small elements, inaccessible or embossed places and corners.

- Confectionery decorations.

Types of spray guns

Since the assortment of spray guns is quite large, it is possible to sort through possible options for a very long time. At the same time, you can’t only focus on the price: for some it will seem sky-high, but the device will pay off very quickly, and someone will buy for a penny, will not get the desired result and will pay again. Therefore, special attention should be paid to:

- Power.

- The quality and thickness of the coating.

- Performance.

- Ergonomics

These indicators can be clarified by considering the different types of spray guns.

Mechanical, or manual action

The simplest representatives of spray guns. They do not paint accurately enough, but, if desired, evenly. Used for whitewashing at home or spraying the garden, as power is not enough for painting, and the operating pressure of the device is 0.4-0.6 MPa. It can work on the principle of a children's water gun or can be made in the form of a tank into which paint is poured, and then air is pumped with a hand pump. An outlet hose with a spray is attached to the reservoir.

Having a very low price, the design is completely independent of the compressor and the mains. But the quality of work and the amount of expendable material leave much to be desired.

Pneumatic

Representatives of this species are considered the most powerful. They take first place among the equipment for painting cars. As a rule, professionals prefer to work with such units, appreciating their good performance, high power and high quality of painting.

All operation of a pneumatic spray gun depends on the compressor with the receiver. Therefore, first of all, the operating pressure (max.), Productivity and volume of the receiver, by which the compressor is selected, are determined.

Electric air

A feature of an airborne electrical device is the spraying of liquids and mixtures using a pump, which is located in the gun body. Spray guns of this series are unpretentious in use, compact and operate from the most common 220V network. The thinnest paint layer applied by them to the surface is identical to the paint layer of pneumatic units. And, although the disadvantage is the appearance of a colorful “fog” during operation, the pluses prevail with sufficient power, the airbrush gives a good performance - up to 0.35 l / min.

Electric Airless (Plunger)

In these devices, a plunger is used to push the mixture out - a piston, the frequent movements of which provide a constant supply of paint. Despite the fact that the models are compact, easy to operate and easy to clean, the quality of the work performed will be imperfect. Since there is no air blowing, it is impossible to obtain very small drops of liquid. But then this equipment (both domestic and professional) is perfect for applying viscous coatings.

Rechargeable

Compact designs are similar to electric spray guns, only equipped with a battery, from the charge of which they work, and an additional tank of 1-2 liters. Visually, they are similar to manual screwdriver. The devices are convenient in operation, they are characterized by a good level of painting, only the price is higher than that of models without a battery, and the operating time is short, so they are relevant for small amounts of work.

An indisputable plus of cordless spray guns is their mobility and the ability to work in the absence of an electrical outlet.

Painting stations

Having a closer look, the structures can be compared with hand-held devices, only made in much larger sizes: a pump and a high-power electric motor - a separate mobile unit, a high pressure hose, and a spray gun - professional.Spray guns with a huge number of adjustments have proven themselves in various industrial fields, when working on an industrial scale using a wide variety of types of paints.

The differences between pneumatics and electricity

For the right choice of spray gun, you need to consider different points. Since all existing and most demanded devices are divided into "pneumatics" and "electricity", we will try to make a comparison:

- The quality of work performed. Pneumatic spray guns are much more powerful than their electric brothers, and paint is sprayed on them into much smaller particles. As a result, "pneumatics" covers any surface with a thinner and more uniform layer of dye.

- "Fog" from the paint. In this matter, the "palm" receive electrical appliances. Moreover, in plunger models the formation of “fog” is generally significantly reduced. That's just an unpleasant addition will be a low level of painting. If you need the perfect option, then only pneumatic devices.

- Use of viscous substances. High viscosity substances will not be a problem for electric spray guns. The main thing is not to put nozzles with a diameter on them, which is not suitable for working with these materials.

- Replaceable accessories. Basically, household electrical devices cannot boast of the ability to replace nozzles. To work with different compositions, the latter will have to be brought to the desired consistency, otherwise most of the working time will be spent on cleaning a clogged nozzle or eliminating smudges that have appeared. At the same time, when working with pneumatic spray guns, it is better to use nozzles of different diameters for various materials. Therefore, the right decision is to purchase a set of elements with different parameters and use them as necessary on one device.

- Fire safety. As for safety, it is important to know that it is forbidden to use electrical equipment in the painting chamber or in closed paint shops and other similar rooms.

Spray gun power

The power of pneumatic spray guns is determined based on the power of the associated compressor and can vary from 0.7 to 3 kW. The most sought after considered devices whose power is in the range 1.2-1.8 kW. This is enough for the good work of all equipment.

Electric paint sprayers with power up to 500 W have an affordable price and do a good job of medium intensity. To household models include:

- The Zubr airborne electric device –– power 350 W (application of mixtures based on diluents and water).

- “Diold” - 400 W (spraying solutions, woodworking and anticorrosive coating).

- "Wagner" - 280 watts (one of the best representatives of this series).

- Hammer airless spray gun - 110 W (application of organic and synthetic compounds).

Devices such as Patriot Pobed KP-300 have very little power - 100-200 watts, but they are great for decorating, decorative for glass and restoration for wood.

Devices with a power exceeding 500 W can be attributed to professional, because they cover the different surfaces as evenly as possible with paints of any density:

- “Forte 750” - power 750 W (portable compressor, tank made of metal, needle and nozzle made of brass).

- "Aspro-1800" - 900 W (mobile, used for processing large areas, painting ceilings and surfaces with a complex profile).

- "Caliber ADB-850" - 850 W (engine - single-phase commutator, the design can work without grounding).

- Enkor KE-700 has a power of 700 watts. For electric models, the higher this indicator, the greater the speed and higher performance. The device is suitable for repair work for a fairly long time.

Spray gun performance

The performance of pneumatics depends on the volume of the receiver. For work at large facilities, professionals use installations with a volume of 100 to 500 liters, while for the performance of housework, a volume of 24-50 liters is enough.

For those who choose a device for performance, it is important to consider that you need to look at a parameter such as “air inlet air”. Data about it indicate on the compressor. To determine the flow rate at the outlet (air), it is necessary to multiply by 0.65-0.7.

For electrical devices, this value is determined by the consumption of paint (liters) per minute. For example, “Special BPO-350” with a flow rate of 0.8 l / min, we can say: the higher the last indicator, the faster the work will be done. In this case, it will take 5 minutes to paint the surface, the area of which is 20 square meters. Turns out that the budget option is approximately 0.5 l / min, the average is 0.8-1 l / min, and floor stations have a flow rate of more than 2 l / min.

Spray gun pressure

Knowing these indicators, you can make the optimal choice of the desired sprayer model:

- 2-2.5 atmospheres (low) - reduces mortar losses to a minimum (20%), but does not provide ideal painting quality.

- 4-6 atm. (secondary) is the most appropriate option. The quality of painting is always good, and the units can work with almost any type of paintwork.

- 5-6 atm. (high) - the painting quality is at the highest level, the surface treatment speed is maximum, but the paint loss is too high.

Low pressure devices - this is usually the choice of masters for painting machines. They work perfectly at a pressure of 2 atm. And save up to 30% of the paint material.

High-pressure equipment (up to 6 atm.) Is an ideal option for working with viscous compounds. With their help, it is possible to apply primers, mastics on a bituminous basis, anti-corrosion compounds.

Diameter of nozzle (nozzle)

An electric spray gun is used to work with many compositions.

Each type has its own nozzle size:

- Enamels - no more than 1.3 mm.

- Acrylic Blends - 1.6 mm.

- Primer - 2.8 mm or more, as, for example, the model "Sturm SG9641".

- Building mixtures - 6-7 mm.

You can select devices that have a nozzle adjustment function and interchangeable nozzles, as in the Wagner W 590.

The universal nozzle size for almost all spray guns can be considered a diameter of 1.4 mm. Must be pay attention to nozzle material - it should be metal, even aluminum with its softness, not brass, but, most importantly, metal. Car painting masters also choose nozzles of different sizes for their pneumatic assistants:

- 1.2-1.3 - base "metallic".

- 1.4-1.5 - acrylic primer, acrylic paint and varnish.

- 1,7-2 – putty liquid.

Spray gun and paint viscosity

When choosing a spray gun, do not forget about the viscosity of paints, mixtures, etc. The fact is that the higher the viscosity of the material and the smaller the nozzle size, the greater the power required to spray the paint.

They cope with such a difficult task:

- Airless spray gun "Sturm SG9612" (viscosity - 80 Din).

- Air devices: SPECIAL BPO-350, MASTER KPE-350, MASTER EKRP-600 / 1.8 (viscosity - up to 60 Din).

To work with wooden surfaces, devices designed for 30-40 Din viscosity are used - Caliber MASTER or Bosch PFS 55.

It is worth noting that for viscous coatings it is better to choose an aggregate with an upper arrangement of the filling glass. Liquids with a higher density will more confidently go down.

Tank volume and location

The paint can be supplied to the gun in two ways: through a hose connecting the paint container and the gun, or from a compact glass cup. The latter are made of metal or plastic:

- In the first case, the user gets difficulty in laundering, but then the visibility of the remaining paint.

- In the second - the tank is easy to wash, but it is not known how much paint material is left in it.

Moreover, glasses for paintwork can be located both above and below:

- In the "top" position you can’t put the tank upright during a break in operation; this arrangement makes the element convenient for use and increases the speed of the painting.

- When the tank is fixed in the “bottom” position, it can be placed on any surface to rest or straighten the wires - this is very convenient. But it must not be tilted so that in no case instead of paint air is sucked in.

Today there are many interesting new developments, and, for example, the 3M company offers a real professional pressurized tank with the PPS system, which has proven itself when working with viscous and thick materials. The glass works as a hermetically closed system, the mixture is prepared and fed to the sprayer without transfusion. The described tank is compatible with the most popular spray guns with the turbo-HVLP system, can be installed in three positions: “top”, “bottom” and “side”, respectively, the spray gun can work even upside down.

Many craftsmen carry out finishing work on large areas and process or paint walls, ceilings, door and window openings, facades etc. To help themselves, they choose equipment with a floor-standing, stand-alone tank with a volume of 7-10 liters.

For work at large construction sites, the profile brigades are equipped with powerful electrical equipment in which the paintwork is taken from a barrel, bucket or any other container.

Weight and cord length

If it takes a considerable amount of time to paint the necessary surfaces and the working unit is not a paint station on a stand, then the weight of the structure will also affect its choice. Usually, the mass of small compact devices is not more than 2 kg. But those who decided to purchase something like the “Bosch PFS 5000E” should be aware that this is quite heavy equipment (up to 5 kg) with a portable pump. But even a woman can easily cope with household appliances like “Wagner W100”.

You also need to determine the length of the hose. For this, two points must be taken into account:

- Hose length Is the distance that you can move away from an external compressor or station.

- Will the device have enough powerto “push” the mixture to the “outlet” with a long hose.

Profiled craftsmen prefer electric outdoor devices (Campbell Hausfeld, Earlex, Wagner).

Gun type

To choose the right pneumatic spray gun, you need to know the main types of devices that are different depending on the pressure and volume of air:

- HP (High Pressure) (pressure is high, air flow is low). The most budget option, although painting can be done at a very good speed. The required pressure is 5-6 bar, paint loss is not more than 50%, a powerful compressor is required. They have an affordable price and are used for various types of paint work.

- Hvlp (High Volume – Low Pressure) (pressure is low, volume is large). When using a high volume of air, work is carried out under low pressure. The pressure at the outlet barely reaches 1 bar, the torch is stable, speed is excellent, ink transfer is more than 65%. Devices are recognized as the most effective and pay off very quickly.

- LVMP (Low Volume – Middle Pressure) (pressure - medium, volume - small). The devices have high performance, air consumption - 270 l / min, effective transfer - more than 65%, differ in the widest spray torch - 28 cm. The device does not work with hammer enamels and paints with abrasive elements.

- LVLP (Low Volume – Lou Pressure) (pressure is low, volume is small). Equipment of the highest category, useful transfer - up to 80%, sufficient air flow - 200 l / min. Pistols are expensive, but differ in minimal paintwork consumption, thin even spraying and very little “fog”.

It should be noted here:

- HUBERTH R500 RP20500-14 - top coat with thick paint.

- Metabo FB 2200 HVLP - continuous operation for a long time. Creating a uniform coating, there are no visible borders between the layers.

- SATAjet 1000 K RP 132134 - a device without a tank with the technology of the modernized color method of high pressure. Suitable for working in draft, preparatory and finishing materials.

- Jonnesway JA-6111 - parts and body are resistant to aggressive paint components, most effective when painting a car.

- MASTAK 671-013C is one of the best low pressure spray guns. It is in demand among car repairmen.

Availability of adjustments

Modern spray guns typically have one to three adjustment systems:

- Needle stroke (nozzle opening). Purpose - regulation in one direction or another of the paintwork volume and, as a result, the creation of a layer of the required thickness.

- Torch. The task is to allow you to choose and configure the most acceptable shape and size of the sprayed spot.

- Air supply. Feature - the ability to change the power of the paint out of the nozzle by adjusting the output pressure.

Ease of use

Choosing a specific model of a spray gun, it’s better to make sure once again that it will be comfortable to use it. It is good if the handle (grip place) will have soft rubber inserts and an ergonomic shape. It is equally important to clarify or check the noise level, especially in plunger devices.

Useful extras

In general, spray guns are purchased for frequent use and for performing considerable volumes of work. To increase the efficiency of devices, they can be supplemented with useful elements:

- Dehumidifier. With high demands on the quality of painting, it is imperative to install this part between the spray gun and the compressor. It will not allow moisture to enter the spray gun from the air, which has become condensate in the compressor and hose.

- Paint pressure tank. This is an additionally installed, hermetically sealed container, which makes it possible to significantly increase the surface area to be painted.

- Air filter. The device cleans the air of solid fine particles.

A few "secrets" of choice

- For one-time workat which the quality is not fundamentally (whitewashing) a mechanical spray gun or plunger apparatus is suitable.

- For frequent painting An electric air device with good application quality is suitable in the house.

- Professionals different specialties it is better to use the "pneumatics" category HVLP or LVLP, which has an external tank.

The use of spray guns in various fields makes it possible to quickly obtain the desired result and avoid many difficulties.

Popular spray gun manufacturers

Currently, the construction equipment market offers a considerable number of spray guns from various manufacturers of different categories.

Most popular devices:

- Wagner. Excellent quality equipment for domestic use and for complex large-scale projects. Most units have a Control Pro - airless spray system, equipped with an innovative nozzle design. NEA technology extends its life.

- Bosch. The technique is suitable for work of varying complexity by both amateurs and professionals. Devices spray any paintwork materials and are equipped with a paint supply function without any additional adjustment; they are characterized by high quality coating.

- SPECIALIST. A wide range of electrical appliances at an affordable price for home use.

- Patriot. The lineup is represented by household spray guns with a very reasonable cost.

- Ryobi. The excellent quality of products and the introduction of new developments appealed “to the liking” of private specialized (construction) teams.

- Sturm. Spray guns are not very expensive, but very well established in everyday life.

- Caliber. Affordable and popular equipment from a Russian manufacturer.Quickly and efficiently copes with everyday tasks.

- Foxweld. Pneumatic spray guns are in demand in auto repair shops. Used for painting and priming cars.

- Hubber. An excellent quality pneumatic tool is used for accurate and accurate work, such as airbrushing.

- Bison MASTER. Equipment economically consumes material, can work with viscous latex mixtures or water-based, as well as drying oil, stain or varnish.

- Energomash. For a very reasonable price, you can purchase a device for uniform high-quality surface painting. Used for materials with a viscosity of 50 Din, can work at an angle of 45 °.

Make the right choice and the result of your efforts will please you very soon.