12 tips on which filler for a sofa is better to choose

What a filler for a sofa is better select? The answer to this question will depend on the desired degree of rigidity and on the purpose of this piece of furniture. For example, if you choose sofa for daily sleep, then the characteristics of its internal filling will be significantly different from the characteristics of the filler sofa, which will stand in the living room or office. From what will be under the upholstery, there will be depend and life time your furniture. Let's consider in more detail all possible options.

1. Spring unit

This option is used already many years and to this day has demand and popularity among consumers. Its main advantage is a high level of comfort, the correct and uniform distribution of the person’s weight in both a sitting and lying position. There are two kind of spring fillers: dependent, which is called Bonnel and independent – "Pocket spring."

- Dependent the block is a system of springs continuously connected to each other. Due to such a tight connection of elements, this type of filler is not able to respond locally to the load and correctly redistribute weight, therefore it is considered less convenient than the option with independent springs. Because of this his price relative low and it is often used to fill budget models of upholstered furniture. Springs can have different diameters and densities per square meter, which affects the level of stiffness and orthopedic properties. Less diameter of elements and the greater their number, the better. The most common option is 100 springs per square meter with a diameter of 10 cm. This type of filler is well suited for sofa in the living room. The springs have an additional coating in the form of polyurethane foam, horsehair or coconut coir. Depending on the type of material, the degree of rigidity also changes. Knowing this feature, you can choose the perfect coating to your taste. Some blocks optional reinforce with a metal frame. In this case, they retain their original shape much longer, which allows them to extend their life.

- Independent unit, This is a newer technology. The innovation is that each spring has a barrel shape and concluded in case from dense fabric. Moreover, it is an independent element, that is, it is not connected with neighboring ones. Diameter springs is 5-6 cm, and density - approximately 250 pieces per square meter. This structure allows you to respond most effectively to the load exactly in the place where it is necessary. Such a mattress does not sag, does not fluctuate with a change in body position and is silent. Thus, he will be as accurate as possible to follow the contours of the body, ensure the correct position of the spine, regardless of the sitting position, and will make the rest most comfortable. Cost such a filler is much higher than the previous version, but due to the additional protection of the springs and their independent placement, it wears out much longer.This option would be ideal if you choose a sofa that will serve as a sleeping place. After all, such a block is most often used for orthopedic mattresses.

To the main the benefits spring blocks include:

- Long service life with proper quality of performance;

- Reliability;

- Ability withstand significant load;

- Surface the sofa will be flat without dents;

- Elasticity and sufficient rigidity, which can be selected depending on the number of springs and their density;

- Free opportunity air circulation which will prevent the appearance of various insects;

- Orthopedic properties which your spine will appreciate.

Disadvantages, Of course, there are also:

- Over time may appear creak;

- Independent blocks have high cost;

- In case of failure of one or more springs, repairs can get by pretty expensive;

2. Polyurethane foam

PPU - this is synthetic, highly porous foamed material, which is obtained by mixing several synthetic polymers. In its density, it can surpass materials such as rubber and rubber. This indicator also affects the quality of products made of polyurethane foam. For furniture, PPU is usually used with an indicator of 30 to 40 kg per square meter. The higher this indicator, the more durable there will be a product. Material with an indicator of less than 30 units is used only for the manufacture of decorative pillows. To find out what filler density your model has, you need to ask passport on the product. For factory furniture, this parameter will be specified. Production technology This material is quite simple, which positively affects its cost.

In its density, it can surpass materials such as rubber and rubber. This indicator also affects the quality of products made of polyurethane foam. For furniture, PPU is usually used with an indicator of 30 to 40 kg per square meter. The higher this indicator, the more durable there will be a product. Material with an indicator of less than 30 units is used only for the manufacture of decorative pillows. To find out what filler density your model has, you need to ask passport on the product. For factory furniture, this parameter will be specified. Production technology This material is quite simple, which positively affects its cost.

Distinguish two kinds PPU:

- Molded polyurethane foam, which initially has a liquid state. It is poured into special forms that repeat the contours and dimensions of the future details of the sofa. Under the influence of high pressure and significant temperature, it hardens. The resulting element is already ready for use and is different high dimensional accuracy. Thus, both the seat and the back or side cushions of the sofa can be made. Disadvantage cast type is the crust, which is formed on the surface as a result of sintering. Air circulation may be difficult in this case, because of which the formation of a "greenhouse effect" is possible.

- Block PPU often called a "sandwich." This is due to the method of its production. The material is in the form of large sheets of various thicknesses and densities. Elements of the required sizes are cut from these sheets and glued together. In this way, various levels of stiffness and height can be achieved. It is because of the presence of several layers that the finished product resembles a sandwich.

For the manufacture of various elements of the sofa, sheets of various degrees of rigidity are also used. Products from PPU do not tolerate direct hits sun rays. Under their influence, they can crumble, therefore mattresses from this material are additionally protect by covers made of lightproof fabric. An interesting feature of some PPU formulations is that they possess shape memory effect. From it usually perform pillowsthat remember the contours of the human body and adapt to them as much as possible. But as soon as you get up, the pillow will instantly return to its original state.

A product with a filler made of high-quality polyurethane foam will cost more affordable than block "Pocket spring", and in their properties and level of comfort approximately the same. Such a mattress can also be used for sleep. The Bonnel will be cheaper than both of these options and significantly worse in technical specifications.

TO the benefits PPU can include:

- Long term operation;

- Absolute security and environmental friendliness of the material;

- Good softness / hardness balance;

- Air- and moisture permeability;

- Material does not provoke allergic reactions;

- Does not accumulate dust;

- Fast shape recovery after deformation due to high elasticity;

- Ability withstand heavy loads for a long time.

Disadvantages this material has significantly smaller:

- Cheap PPU quickly loses its elastic properties, which is why dents will appear in the places of greatest stress soon:

- Some types of PUFs may seem pretty tough compared to the spring unit.

3. Sintepon

Highly common material that is used as filler in inexpensive models. It is a synthetic material in the form of a non-woven fabric. It is made from polyester fibers.  Optimal option will use it in combination with other types of filler. Usually he serves as an intermediate layer between a full filler material, such as PUF, and upholstery. It gives the finished product extra softness and elasticity. TO the benefits sintepona include:

Optimal option will use it in combination with other types of filler. Usually he serves as an intermediate layer between a full filler material, such as PUF, and upholstery. It gives the finished product extra softness and elasticity. TO the benefits sintepona include:

- Low cost;

- Environmental friendliness material due to which it is not prone to appear fungus inside the fibers;

- Despite its synthetic origin, synthetic winterizer does not cause allergies and can be used as a filler even for furniture in a children's room;

- His structure elastic and elastic.

Despite all the positive qualities, he has a number significant disadvantages:

- The most basic is short operational period. With active use and frequent loads, this material loses its elastic properties, and dents and bumps quickly form on the surface of the product. Therefore, despite the affordable cost, furniture filled with synthetic winterizer will last a very short period.

- At the moment, there is no single technology for the production of this material. Therefore, you risk acquiring low-quality product in the manufacture of which harmful substances could be used. To avoid this, be sure to ask the seller for a product certificate that can confirm its safety.

- As a full-fledged filler, it can be used only for pillows or armrests, in some cases - for the back, in order to give it decorative bends or protrusions. For example, if the back of the sofa is made using the “carriage coupler” technology;

- With time goes astray into lumps.

Having assessed the advantages and disadvantages, we can conclude that such material is better suited for the sofa to be used in living room.

4. Periotek

it modern non woven material, which consists of high quality polyester fibers. It is more often used for the manufacture of mattresses and various bedding, as well as for filling upholstered furniture. Thanks special additives in the form of artificial components (for example, corn fibers, bamboo or viscose), or natural fibers (wool, coconut, flax or cotton), this material possesses high durability and elasticity. Together with these indicators, the service life of products with such a filler also increases. To strengthen perioteka can additionally be used knitted fabric - doubler, non-woven single-stitched or needle-punched fabric or woven fabric, such as calico. To understand exactly which components are included in the composition, and what stiffness indicator this filler can provide, it has special marking. It also indicates the density and width.

To strengthen perioteka can additionally be used knitted fabric - doubler, non-woven single-stitched or needle-punched fabric or woven fabric, such as calico. To understand exactly which components are included in the composition, and what stiffness indicator this filler can provide, it has special marking. It also indicates the density and width.

To obtain this, while unusual for us, material is used special technology. It consists in shaping three of various layers. First the layer is the main one; it must bear the entire load.Its fibers are stacked in a vertical direction and are fixed in this position under the influence of high temperature. Second and third layer perform the function of reinforcing. They strengthen and support the first layer. Such unique structure and explains the high technological performance of this type of filler.

Benefits perioteca obvious:

- Material is hypoallergenic;

- In its structure impossible reproduction harmful and pathogenic microorganisms;

- He is completely safe for human health. This is due to the fact that in its composition there is no glue, resins and other components that may be toxic. The fibers are held together by temperature.

- Periothec mattresses provide very high level of comfort;

- Able to restore shape with low rate of permanent deformation even with prolonged exposure to significant loads;

- Indicator its elasticity and mass distribution is similar independent spring block;

- Durability, thanks to a three-layer reinforced structure;

- Breathability;

- Fire safety.

TO disadvantages can include:

- Cost which is equal to the cost of the "Pocket spring" block.

- This material is ideal for filling upholstered furniture, but for some it may seem too tough. In such cases, it is used as the main, elastic layer, and softer materials are additionally used to achieve a lower degree of rigidity.

Such a sofa can use for daily sleep After all, the degree of its deformation is practically minimized.

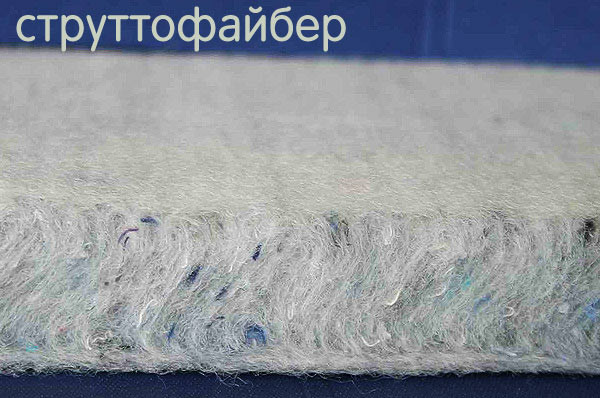

5. Struttofiber

One of the most elastic types of modern fillers, which is ideal for filling upholstered furniture. His middle name, "Non-woven independent springs", speaks for itself. It is made from synthetic and natural fibers, such as cotton, linen, coconut, camel hair, or combinations thereof. Manufacturing technology recalls the process of obtaining perioteca. The fibers of the carrier layer are also stacked vertically and are fixed by a stream of very hot air. This technology is called Strutto. Due to this, the finished material has increased elasticity and wear resistance.  is he as much as possible definitely capable take contours body and prevent the appearance of problems with the musculoskeletal system. Strutofiber has a number of significant advantages:

is he as much as possible definitely capable take contours body and prevent the appearance of problems with the musculoskeletal system. Strutofiber has a number of significant advantages:

- is he not subject to decay;

- Term his exploitation very large;

- Due to the increased elasticity is better than other fillers restores form after prolonged exertion;

- Withstands large weight

- Does not absorb moisture;

- Do not support process burning;

- Breathable;

- In this material impossible appearance dust ticks and other microorganisms;

- Hypoallergenic;

- Does not produce extra noise and squeaks;

- It has reasonable cost.

You need the right choice of stiffness for different weight categories, for example:

- Filler with high rigidity recommended for people weighing 90 kg or more;

- Middle level stiffness can withstand loads weighing from 60 kg to 90 kg;

- Soft the filler is recommended for use by people whose weight does not exceed 60 kg.

Due to such weight restrictions, difficulties when choosing among older people who are uncomfortable sleeping or sitting on a hard surface, but whose weight exceeds permissible norms.

6. Felt and padded jacket

Felt is a non-woven fabric. natural origin which is obtained from felted goat or sheep wool. The structure of these types of wool allows you to get a very dense material, the formation of which uses high temperature pressing.It is rolled through hot cylinders, after which a fairly strong and hard crust is obtained on both sides of the sheet. Felt is available in the form of panels that have different thicknesses. Padded jacket represents composition from cotton wool, the layer of which is 5 cm thick and a dense fabric that covers it on both sides. It can be a packing, bag, gauze or technical calico. To connect all the layers to each other, use the machine line with dense threads at a certain interval.

Padded jacket represents composition from cotton wool, the layer of which is 5 cm thick and a dense fabric that covers it on both sides. It can be a packing, bag, gauze or technical calico. To connect all the layers to each other, use the machine line with dense threads at a certain interval. IN quality 100% filler upholstered furniture these two materials do not accepted to use due to their excessive density. However, felt serves as protective layer for spring or PPU blocks, making their surface more wear-resistant and protecting them from bursting. This significantly increases the life of the products. Padded jacket is used as intermediate layer between fillers. It is used to increase the comfort and convenience of a bed. These materials have many advantages:

IN quality 100% filler upholstered furniture these two materials do not accepted to use due to their excessive density. However, felt serves as protective layer for spring or PPU blocks, making their surface more wear-resistant and protecting them from bursting. This significantly increases the life of the products. Padded jacket is used as intermediate layer between fillers. It is used to increase the comfort and convenience of a bed. These materials have many advantages:

- Protective properties which increase the service life of upholstered furniture;

- Natural ingredients in the composition, which allow the use of this filler even for small children's sofas;

- High density and wear resistance;

- Affordable price;

- Hypoallergenicity;

- Opportunity uniform load distribution;

- Good regulates heat.

- Smooth surface even after many years of use.

To substantial disadvantages relate:

- In natural wool can get insects and other pests;

- This coating is good absorbs moisture and can quickly to mold because of what it is necessary to constantly dry it, which is extremely difficult to do if we are talking about fillers for the sofa.

7. Hollofiber

Can say that itadvanced synthetic winterizer. It resembles fluffy balls of small sizes, which are formed from polyester spiral fibers of polyester and have many internal pores.  Thanks spiral structure it has the main advantage, which is very appreciated when choosing a filler for upholstered furniture - it is able to quickly restore shape after prolonged stress. However, he remains very soft and warm. It is actively used as a filler for sofa cushions and seats. If holofiber in the form of balls is used for pillows, then a special one is used to fill the seats furniture material. It looks like a mat with the same spiral structure. It is very thick, resilient, and keeps its shape well.

Thanks spiral structure it has the main advantage, which is very appreciated when choosing a filler for upholstered furniture - it is able to quickly restore shape after prolonged stress. However, he remains very soft and warm. It is actively used as a filler for sofa cushions and seats. If holofiber in the form of balls is used for pillows, then a special one is used to fill the seats furniture material. It looks like a mat with the same spiral structure. It is very thick, resilient, and keeps its shape well.  Today it is considered one of the most quality fillers. This is due to a large list of him positive qualities:

Today it is considered one of the most quality fillers. This is due to a large list of him positive qualities:

- Absolute security and environmental friendliness, which makes it possible to use it to fill children's furniture;

- Does not cause allergies reactions;

- It has light weight;

- Does not absorb odors;

- Not absorbs and does not collect on its surface dust;

- Easy changes and restores shape;

- In him not may form harmful microorganisms;

- Possesses high softness and elasticity;

- Does not absorb moisture;

- Breathable;

- Does not roll;

- Does not support combustion;

- It has long term service.

Significant disadvantages this material not found. Unless, a higher cost than the synthetic winterizer.

8. Foam rubber

Most available at cost and most low quality type of filler. Foam rubber is the same polyurethane foam, but lowest quality and the lowest density. Therefore, it is a mistake to assume that these are two different materials. Very often sellers can deceive customers arguing that this is not so. In fact, they differ only in their characteristics. By the way, the thickness of the foam does not affect the degree of its rigidity.Even a high sheet can easily wrinkle and be very porous, while thin, it can instantly restore shape. Foam rubber rarely used as filler for soft sofas.  Unless, for their armrests or fables. He found his application as a material for kitchen sofas.

Unless, for their armrests or fables. He found his application as a material for kitchen sofas.

His positive sides this is:

- Low cost;

- Security for good health;

- Antistatic properties;

- Hypoallergenicity;

- Good lets air through and moisture;

- Not opportunity mold formation.

Disadvantages, Unfortunately, very significant:

- Fragility;

- Low quality foam rubber very fast loses elastic properties why dents form on the surface;

- With time dries up and crumbles;

- Not is intended for filling furniture which is subject to intensive exploitation.

As you can see, such a filler will become unusable very quickly, and your sofa will quickly lose its aesthetic appearance.

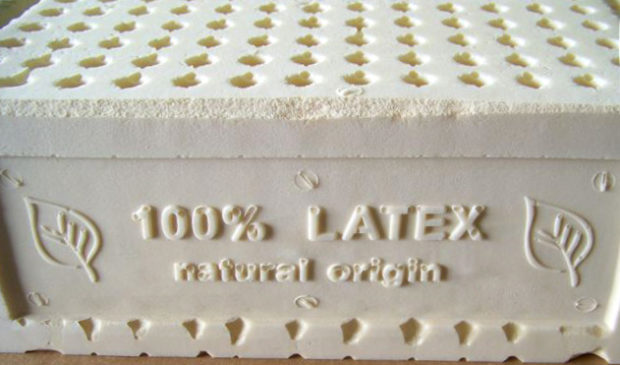

9. Latex

It's a filler natural origin which is used in expensive models of upholstered furniture. It is made from rubber plant juice which significantly increases its cost. At vulcanization latex manages to obtain a structure that has a lot of cells that facilitate the penetration of air and are responsible for hygroscopicity. Production technology latex, which is used in the furniture industry, is quite simple. The latex mixture is poured into a container in which it is constantly mixed and foams after a certain period of time. After that, it is poured into special forms and at a temperature of 100 ° C, the process of vulcanization occurs. The resulting preform is removed from the mold, cleaned of unnecessary foam residues and dried at a temperature of 120 ° C. After that, the sheets are tested for stiffness, weighed, packaged and sent to the furniture factory. Due to the fact that rubber in its natural form does not tolerate hit fat ultraviolet light and collapses from this, in the production of latex mixtures use special stabilizing additives. Thus, the maximum proportion of natural rubber in latex foam is no more than 85%. Such a product is considered completely natural. If we talk about the requirements for filler for soft furniture then the allowable latex content is 45-60%. This indicator is quite enough to obtain the required level of strength, elasticity and wear resistance. If you are not limited in finances and prefer to use furniture made from natural materials in your home, we recommend that you pay attention to this type of filler.

Due to the fact that rubber in its natural form does not tolerate hit fat ultraviolet light and collapses from this, in the production of latex mixtures use special stabilizing additives. Thus, the maximum proportion of natural rubber in latex foam is no more than 85%. Such a product is considered completely natural. If we talk about the requirements for filler for soft furniture then the allowable latex content is 45-60%. This indicator is quite enough to obtain the required level of strength, elasticity and wear resistance. If you are not limited in finances and prefer to use furniture made from natural materials in your home, we recommend that you pay attention to this type of filler.  He possesses a number advantages:

He possesses a number advantages:

- Lifetime makes about 20 years;

- Does not cause allergic reactions;

- Breathable;

- As much as possible for sure repeats the contours body;

- Capable of dampen vibration;

- Distributes the load evenly due to which orthopedic properties are inherent in it;

- Non toxic

- Highly quickly restores shape.

TO disadvantages can only be attributed to him high cost which is determined by the specifics of the production and the components used. There is also artificial latex. So called highly elastic polyurethane foam. To don't be deceived you need to know that the natural filler has a grayish tint, and to the touch, it seems greasy. While synthetic - it has a yellowish tint and is dry to the touch.

10. Durafil

This material has structure which in terms of similar to a spring block. This is a high-quality non-woven fabric that is made from hollow polyester fibers by heat treatment and gluing the fibers to the base. His fiber situated upright and, as it grow out of the base, resembling grass. This structure allows you to achieve high elasticity combined with softness and splendor. This material perfect fits for filling sofas giving their backs and seats volume and attractive appearance. Such furniture looks very cozy and comfortable, and in fact it is. His advantages make this material more popular every day:

This material perfect fits for filling sofas giving their backs and seats volume and attractive appearance. Such furniture looks very cozy and comfortable, and in fact it is. His advantages make this material more popular every day:

- Hypoallergenic material that does not contain substances that can cause even the slightest allergic reaction;

- Do not support process burning. This is due to the peculiarity of production, in which it is subjected to special heat treatment and loses combustible properties. It may char, deform, or collapse completely, but not ignite at the same time.

- High elasticity, which was achieved thanks to vertically directed individual fibers. Such a structure is actively resists load upon the disappearance of which, the fibers instantly tend to occupy their original position.

- This material does not accumulate dust;

- Steady moisture and temperature changes;

- Possesses antimicrobial properties;

- Enjoyable softness what makes it popular in the furniture industry;

- Long service life.

Disadvantages this material so far not found. And, based on the list of its positive qualities, we can conclude that a sofa with such a filler can be used as a full sleeping place.

11. Lamels

Do not forget that if you are looking for a sofa that can play the role of a berth, then to achieve orthopedic properties and extending its life, it is necessary to choose models that are additionally equipped with slats. Of course, this is not a kind of filler, but only additional support for him, which is very useful. Lamels represent veneered wood slats that have a slightly curved shape. This design allows you to compensate for the load and ensure the correct position of the body. At pressure, they bend, allowing you to evenly distribute the load.  The material used is birch, poplar or beech. The thickness of the lamellas is 2-10 mm. It is clear that the thicker this element and the more often it is located on the frame, the stronger and more durable it will be. Disadvantage lamellas is that in case of breakage they cannot be repaired. However, almost everyone can buy a new one and replace it on their own. Especially, given their low cost and the possibility of acquiring even one piece.

The material used is birch, poplar or beech. The thickness of the lamellas is 2-10 mm. It is clear that the thicker this element and the more often it is located on the frame, the stronger and more durable it will be. Disadvantage lamellas is that in case of breakage they cannot be repaired. However, almost everyone can buy a new one and replace it on their own. Especially, given their low cost and the possibility of acquiring even one piece.

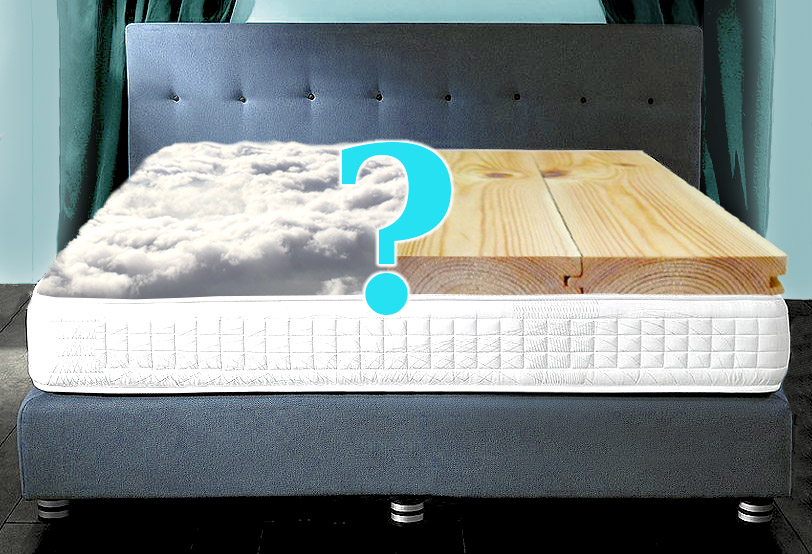

12. The leader among the fillers, depending on various evaluation criteria

We have listed quite a few different options for fillers and you are probably already a little confused. To clarify, summarize and select the most suitable species depending on various requirements.

Average operating life

- Latex - about 20 years;

- Periotek, Struttofiber and durafil - about 10 years or more;

- Spring loaded block - 7-10 years;

- PPU - 5-8 years;

- Hollofiber - 5-10 years;

- Foam rubber - 3-5 years, and then, in the case of a very careful attitude to him.

When using the sofa as a berth

- Spring loaded block;

- Periotek;

- Blocky polyurethane foam;

- Durafil;

- Latex.

For seating with constant and heavy loads

- Spring loaded block;

- PPU;

- Hollofiber;

- Periotek;

- Strutofiber;

- Durafil.

When choosing a sofa, note that quite often used combined fillers, which allow to achieve optimal performance rigidity / convenience and value for money. Be sure to ask the seller more about all types of fillers used. Ask certificates which confirm the safety of materials. AND the most important thing - Be sure to sit down or lie down on the selected sofa. You should be comfortable and comfortable on it. It is in this case that you will be satisfied with the purchase.

The corner sofa consists of two sofas of 2.5 m each. Change filler and upholstery from high-quality imp fabric, one back