6 tips for choosing a heater for sewer pipes

When it comes to water pipe insulationprudent owners take this for granted. But when in addition it is recommended to insulate pipes for sewage, such advice is skeptical. But imagine for a moment that an ice plug has formed in the sewer pipe, which interferes with the movement of effluents. Such a nuisance instantly makes the living conditions in the house, to put it mildly, uncomfortable. In an even worse situation, a frozen fluid can simply burst a pipe, because it is no secret that when it freezes, it has the ability to expand and increase in volume. Is it necessary to say that under the conditions of severe frosts and freezing of the soil to a greater depth, repair will not be possible until the thaw? Recall that before the arrival of heat, you will have to do without the much-needed benefits of civilization. So that you do not have to experience such a “joy” on your own experience, listen to the tips on the need for this event and recommendations for the choice of insulation for sewer pipesthat we have dedicated today's article to.

1. Methods of protecting pipes from freezing

From the preface to the article, you could already present in all colors what the consequences of freezing are fraught with sewer pipes. Therefore, we will no longer return to the question of whether this is really necessary, but immediately consider directly the methods of insulation. In practice, really usable methods are:

- Laying sewer pipes to a depth which exceeds the level freezing ground at least 10 cm. If this condition is met, then insulation as such may not be required. This method seems simple to execute only at first glance. But let's figure it out. Let’s say the level of freezing in your region is at a depth of 1.5 meters. So, pipes must be buried at least 1.6 meters into the ground. Given that for normal operation, sewer pipes should have at least a minimum slope, the depth can increase to 2-2.5 meters. Meansseptic tank (if available) will need to be deepened by 2.5-3 meters. Agree, doing it yourself will be very hard physically and for a long time. Just imagine how much earthwork you have to do. In addition, if the pipeline passes at such a depth, its repair will be complicated. Summarize. This method of insulation can be implemented if you have special equipment that will greatly simplify and speed up the work, and the septic tank model provides for the possibility of placement at such a great depth;

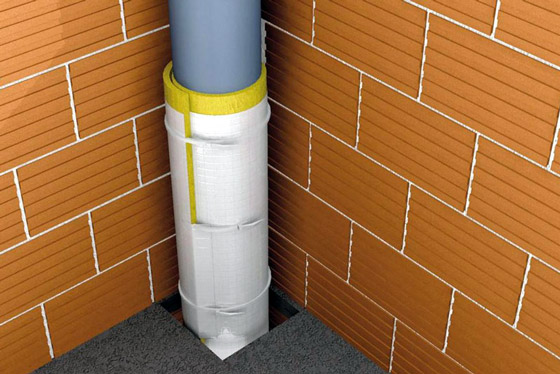

- Thermal insulation materials. This method is one of the most optimal. The benefit of the variety of insulation materials allows you to choose the option that suits you, both in cost and depending on the material of the sewer pipes. In addition, it is quite possible to isolate pipes in this way independently, because installation is extremely simple and does not require special knowledge. The only thing I would like to focus your attention on is that such work should be carried out immediately at the time of laying the pipeline.We will tell you more about the types of insulation materials in the following paragraphs;

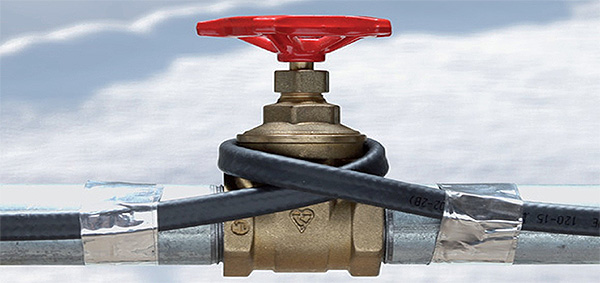

- Warming from using a heating cable. This method and this invention of mankind is gaining increasing popularity. This is not surprising, because having invested once a certain (most often considerable) amount of money, you will get a system that, if used correctly, can last you more than a dozen years and will fully pay for itself. About what types of heating cable are, and recommendations for its selection, you can find in our article by going to this link. The heater can be installed both externally and internally, depending on the diameter of the pipes and the condition of the pipeline. Even a pipe filled with concrete can be insulated with a heating cable, so pay attention to this method;

- The combined method. To enhance the effect, or if your climate zone is characterized by abnormally low temperatures, it is rational to combine several methods of protection in order to really achieve the desired result and not waste your energy and money. Alternatively, pipes buried by a sufficient amount additionally fall asleep expanded clay, or enclose in a foam or other shell. With a small pipeline laying depth, it is rational to use a heating cable and additional external insulation, etc.

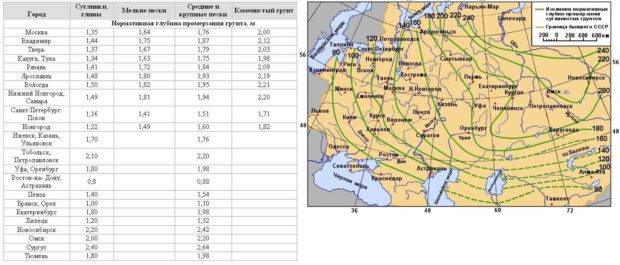

Determining factor the need for insulation sewer pipe is undoubtedly the climatic zone in which you reside. Residents of the southern regions, where the temperature may not even fall below zero degrees, will not need it at all. The remaining regions should be guided by the depth of freezing of the soil. To make it easier for you to decide which way to choose, check out the table that shows the average data.

Determining factor the need for insulation sewer pipe is undoubtedly the climatic zone in which you reside. Residents of the southern regions, where the temperature may not even fall below zero degrees, will not need it at all. The remaining regions should be guided by the depth of freezing of the soil. To make it easier for you to decide which way to choose, check out the table that shows the average data.

2. Requirements for thermal insulation materials

Before proceeding with the choice of insulation, you need to understand what properties he must possess in order to cope with his task.

- For safe operation, the material must be non-combustible;

- A prerequisite is water resistance. Since wet insulation in most cases loses its heat-insulating properties;

- Sure, it's durability.

- It is not recommended to choose materials that contain cellulose, since it quickly disintegrates when exposed to soil;

- Installation of the material should be simple and not require the purchase of expensive fasteners;

- Reusable. Imagine that the installation of the pipeline was leaky, and a leak formed at the joint of the two pipes. To eliminate it, you must first remove the insulation layer from the pipe. It will be much more economical if the material retains its shape, and you can reuse it on the repaired area;

- For high-quality insulation, the material must have a low coefficient of thermal conductivity;

- Also, it must not react with any biological or chemical compounds that may be in the surrounding soil;

- If we are talking about the insulation of a pipeline passing underground, the material must be stiff enough to withstand the pressure of the earth, not to deform, and at the same time not to exert additional pressure on the pipes;

- Do not respond to sudden changes in temperature and other environmental factors;

- It is also worth paying attention to materials that have an additional foil layer, which acts as a protection against moisture. Such materials cost more, but sometimes you can not do without it;

- Well and most importantly - the cost of insulation should not be such that the insulation work turned out to be “gold”.

3. Mineral wool insulation

According to standards, the material belongs to the class of fibrous and is made using molten rocks and metal slag.Three main varieties can be distinguished. mineral wool:

- Glass wool - mineral thermal insulation material, which is obtained from the same materials from which glass is made. It received great demand due to its affordable cost and low thermal conductivity - 0.030 ... 0.052 W / m * K. Also, cotton wool shows good resistance to vibration loads, chemical resistance. The density in the loose state is not more than 130 kg / m3. Glass wool in its properties differs from other varieties. It has a fiber thickness of 3-15 microns, and a length of 2-4 times greater than that of stone (basalt) wool. The insulation is stable when exposed to temperatures up to 450 ° C. The disadvantages include the fragility of the material and its increased fragility. Also, when working with this material, it is necessary to reliably protect your hands, since upon contact, small sharp needles easily penetrate gloves and cause unpleasant burning and itching. Inhalation of air in which particles of glass wool soar is considered more dangerous. They instantly cause long-term lung irritation and are eliminated very slowly. The same goes for the organs of vision;

- Slag wool - produced from slag waste obtained during the smelting of pig iron. It has high friability and residual acidity. In this regard, when used in conditions of high humidity, oxides are formed on its surface that adversely affect the surface of plastic or metal pipes. The thickness of its fibers is 4-12 microns. The thermal conductivity is much higher than that of glass wool - 0.46 ... 0.48 W / m * K, as well as the coefficient of water absorption. In addition, slag wool has low environmental properties. The insulation retains its properties when heated to a temperature of no more than 300 ° C, but is unstable at temperature extremes. Because of this, the service life is significantly reduced;

- Stone or basalt wool - It is made mainly of molten gabbro-basaltic rocks. It is a non-combustible material capable of withstanding record high temperatures without starting the reflow process - up to 870 ° C. However, when exposed to temperatures reaching 600-700 ° C, it begins to decay and turn into dust. The structure of the material is porous, due to which it has high rates of heat and sound insulation. The thermal conductivity coefficient is quite low - 0.035 ... 0.039 W / m * K. This is achieved due to the fact that the air in the pores of the material is in a static state. The vapor permeability index is 0.25 ... 0.35 mg / m kV. * H * Pa. The density of stone wool lies in the range from 30 to 200 kg / m3. and depend on the form of release. For example, stone wool slabs can withstand a load of 700 kg / m 2.

Glass wool and stone wool can be produced with additional protective layer from foil, fiberglass or kraft paper. Stone wool does not absorb water, but constant exposure to moisture can gradually disrupt the structure of the insulation.

4. Foamed polyethylene as insulation

This material is obtained by foaming polyethylene with carbohydrates. The final product has high resilience and elasticity. Its structure has a closed cellular structure. Has the following release forms:

- Rolls

- Sheets;

- Harnesses;

- Shell.

The density of polyethylene is 40 kg / m3, which is not so much. The thermal conductivity is approximately 0.05 kV / m * K. The thickness of the material is insignificant, which saves space or insulates pipes where there is simply not enough space for other materials. However, to achieve a better result and the use of polyethylene in rolls, it is recommended to wrap pipes in several layers.

Consider advantages material:

- Absolutely does not absorb moisture, which helps protect the surface of the pipes from the development of corrosion and the accumulation of condensate;

- It has noise and shock absorbing properties, due to which it is an excellent sound insulator;

- Despite its synthetic origin, it is environmentally friendly;

- Resistant to various aggressive substances, for example, such as liquid concrete or cement, lime, gypsum, various oils and gasoline;

- High elasticity and flexibility allows you to warm not only smooth areas;

- Easy installation and reusability;

- Low cost.

For the insulation of sewer pipes, polyethylene in the form of pipes or sheets is best suited. Hollow cylinders are intended for warming steel, copper, plastic pipes with a diameter of 7 to 114 mm. In this case, the thickness of the insulating layer can be from 6 to 20 mm. For pipes with a large diameter or non-circular section, it is more convenient use sheets or rolls with an additional foil layer. Fasten the material to a special glue, staples or reinforced adhesive tape.

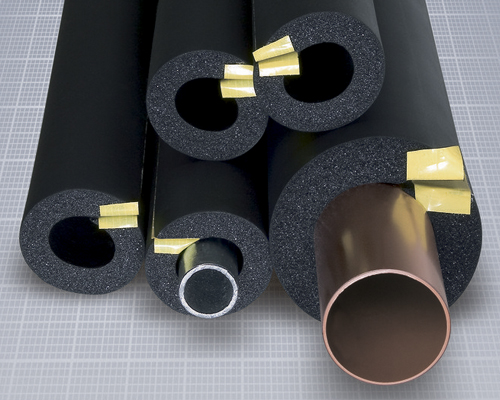

5. Thermal insulation with foamed rubber

This insulation is made on the basis of natural or combined rubber and is referred to as elastomers. That is, to materials with a high elasticity index. It is worth noting that mounting insulation occurs hot stitching method after which a strong seam is formed. To simplify installation, some manufacturers produce rubber hollow cylinders with a technical cut, on the edges of which there is already an adhesive layer under the protective tape. To fix such insulation on the pipe, it is enough to remove the protective strip and firmly connect the ends of the two halves.

Synthetic rubber has a fine cellular structure of a closed type, so it has number of advantages:

- Low coefficient of thermal conductivity;

- Resistance to moisture and steam, which is maintained throughout the entire life cycle;

- The material has excellent adhesion to any surface at the molecular level;

- Due to its high flexibility, it is possible to perform hermetic thermal insulation;

- It retains its properties during sudden changes in high temperatures (from -200 to + 150 ° C). This makes it possible to use it in harsh climatic zones;

- Durability without loss of quality;

- High noise insulation properties;

- The composition of the material includes a large number of extinguishing agents. This is an extremely important point when it is necessary to carry out insulation work in areas with increased fire hazard;

- Absolute safety for health, hygiene, non-toxicity;

- The ability to reuse the insulation, which makes it economically viable.

Foamed rubber is suitable for insulating pipe insulation produced in sheet form or hollow tubes various diameters. It has a standard cross-section for pipes with a diameter of 6 to 114 mm. The insulation thickness reaches 6 -32 mm. For larger pipes, sheet rubber is intended. Fixation of the material occurs in the same way as polyethylene sheets.

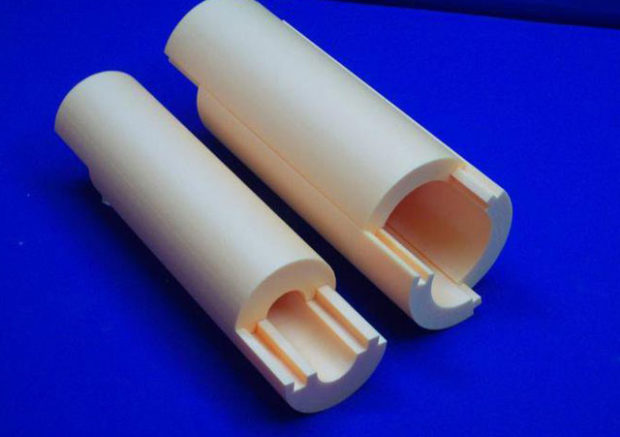

6. Shell for insulation of sewer pipes

Many use insulation in the form of sheets, which is wound on pipes or laid around them in special protective boxes. All this is very long, does not provide the necessary fit of the material to the surface of the pipes and requires additional costs for the organization of the installation site. It is much simpler, faster and more convenient to use a ready-made shell, which has a standard inner diameter equal to the outer diameter of the sewer and water pipes. You only need to connect the two halves together. The following types of shell are distinguished by the material of manufacture:

- From the made foam polyethylene. It is a hollow cylinder with a slot along the entire length, which is characterized by increased flexibility. This type of insulation can be used in the range of operating temperatures from -40 to + 90 ° C. Attracts material at an affordable cost.The insulation itself is susceptible to moisture, therefore it is recommended to additionally carry out a waterproofing coating;

- From expanded polystyrene (polystyrene). Such a shell is distinguished by high density and, accordingly, high rigidity. Foam cylinders can be of two types - with a lock part on both edges and without a lock connection. Such a heater practically does not absorb moisture and is characterized by excellent thermal insulation properties. It can be used at temperatures from -50 to + 80 ° C. Foam shells are actively used not only for insulation of sewers, but also for water supply and air ducts. The rigidity of the structure is sufficient to insulate the pipelines buried in the ground and withstand its pressure. The material does not lose its integrity even when the subsidence of the soil;

- From polyurethane foam. Many experts claim that this is one of the best heaters. Its structure consists of almost 95% closed cells and has a minimal rate of water absorption and vapor permeation. Given the above options, polyurethane foam has the lowest coefficient of thermal conductivity. A wide range of operating temperatures - from -180 to + 130 ° C allows you to use it for pipe insulation in the most adverse climatic regions.

Besides insulation made in the form of shell from polystyrene foam and polyurethane foam has following advantages:

- Quick installation and the ability to install without the use of additional fasteners;

- Small specific gravity thanks to which you can not worry about a significant weighting of the structure;

- Tight fit to the surface of the pipe;

- No need to carry out additional waterproofing;

- The surface is not subject to the formation of fungi or mold and is not susceptible to their effects;

- Various rodents do not like these materials;

- Long service life, which can reach 50 years;

- Reusability.

In addition to the above advantages of the insulation in the form of a shell, it should be noted that the expanded polystyrene shell with an additional protective shell from moisture is considered the best insulation for metal sewagelaid in the ground.

In addition to the above advantages of the insulation in the form of a shell, it should be noted that the expanded polystyrene shell with an additional protective shell from moisture is considered the best insulation for metal sewagelaid in the ground.