7 tips for choosing furniture bolts

Previously, furniture was assembled using wooden dowels and corners. Now more convenient and durable fasteners have appeared. Along with confirmations and eccentric couplers, furniture bolts are widely used. They are somewhat different from conventional hexagon head construction bolts, provide reliable fastening of furniture parts and do not spoil its appearance. Of course, when a ready-made table or bed is bought, few people are interested in the type of fasteners used, but if you decide to assemble furniture at home or repair a factory product, you will have to figure out how to choose furniture bolts, what types and sizes they come from, from which materials and by what standards are manufactured.

No. 1. Distinctive features of furniture bolts

The bolt is one of the most common fasteners. Everyone knows that it consists of a cylinder head and a rod. On the rod there is a thread on which the nut is screwed. The most common building bolts have a hexagonal head; they are used both in private construction and in the construction of industrial facilities. There are also especially strong machine-building and road bolts, ploughshare bolts with countersunk heads (used in agriculture), as well as more rare rail and elevator bolts.

The furniture bolt even differs in appearance from the usual construction. First of all, it "gives out" semicircular hat. The rod may have a full or incomplete thread. Under the head is a mustache or square heading. This element is necessary so that when tightening the nut the bolt does not turn, and the fastening does not loosen. The headrest or mustache rests on a wooden piece of furniture and prevents unnecessary rotation.

Mustache furniture bolt

The semicircular head due to the absence of sharp edges and any protrusions ensures maximum safety of furniture with such fasteners. It is impossible to cling to a furniture bolt, it does not spoil the appearance of the product, since after installation only a smooth surface of the cap will rise above the part. Such bolts are in every modern armchair, sofa and bed.

For production, mainly stainless steel with galvanized coating is used. Less common are bolts made of hard plastics and aluminum. Furniture bolts are inferior in strength, for example, to machine-building bolts, but they also cost several times less. Yes, there is no such heavy load on furniture hardware, but this does not mean that you can buy the first bolts that come across. It is better to check with the seller for a certificate of conformity and quality - this is a guarantee that the fasteners made will be reliable and durable. Qualitative and certified products are sold by the Rusmetiz store.

Furniture bolt with headrest

No. 2. Scope of application of furniture bolts

Where else to use furniture bolts, no matter how in the furniture industry? All right. The main purpose of this fixture is to connect furniture parts, but the convenient design with a semicircular head was highly appreciated by builders and began to be used in other areas.

At the moment, furniture bolts are used for such purposes:

- in the manufacture of tables, chairs, sofas, beds, cabinets, chests of drawers, kitchen sets and other furniture;

- when repairing furniture, when replacement of old bolts is required.By the way, when moving furniture can be disassembled by unscrewing part of the fasteners, and assembled in a new place using existing bolts, because they are not disposable;

- for joining wooden parts in private construction and repair, for example, when creating stairs and arbors;

- in some other areas (mechanical engineering, roadwork, construction of bridges, production of door locks), when it is necessary that the height of the hat is minimal and the site itself is not responsible.

No. 3. Production standards and furniture bolt size

A quality furniture bolt is one that is manufactured in full compliance with the standard. It remains to figure out what kind of standards are used, because there are several of them:

- GOST 7801-81 dedicated to bolts with a mustache and an enlarged semicircular head. According to it, bolts with a thread from 6 to 20 mm cross-section are produced (in marking M6-M20) The height of the head ranges from 3 mm for M6 to 10 mm for M20, the cross section of the head is from 14 to 44 mm, respectively. The length of the bolt can be from 25 to 200 mm, the length of the thread is from 18 to 46 mm, the height of the mustache is from 3 to 9 mm. This standard does not produce bolts of certain lengths. Weight of 1000 pieces of the smallest bolts (M6, length 25 mm) - 6.5 kg, and the largest (M20, length 200 mm) - 484.3 kg;

- GOST 7802-81 adjusts the geometry of bolts with square headrests. The thread cross section for such bolts is 5 to 24 mm (M5-M24), and the head cross section is 11 to 52 mm. Depending on the size, the height of the head is 2.5-12 mm, the head is from 3 to 15 mm, the size of the head on each side is from 5 to 24 mm. The length of the thread is from 16 to 60 mm, the length of the entire fastener is 12-260 mm. The weight of the smallest bolts is 2.7 kg / 1000 pieces, the largest - 911 kg / 1000 pieces.

- DIN 603 - The German standard, an analog of our GOST 7802-81, but in some respects differs slightly from it. The standard allows the production of M6-M8 bolts from hard plastics, for M10-M20 bolts it is mandatory to use stainless steel (A4 or A2), as well as brass compositions. Standard bolts receive a head with a diameter of 12.45-46.8 mm and a height of 2.7-11.05 mm. The height of the head is 2.9-14.1 mm, the length of the thread is 16-65 mm, the length of the fastener is 16-200 mm, the head on each side projects 4.52-20.84 mm. The mass of 1000 pieces of products is from 4 to 597 kg.

The exact dimensions that this or that fixture should have are best looked for in official standards and should be guided by these indicators when buying. Nuts are selected according to the size of the bolt.

Do not confuse furniture bolts with furniture screws. The latter receive a hexagonal head, which during installation is completely recessed into the product. The screws are manufactured according to DIN 912 and our standard 11738.

Number 4. Material of furniture bolts

Indirectly, we have already touched on this topic, considering various standards, but now we will consider in more detail. Furniture bolts used to be made of metal that was not protected against corrosion. Even if the humidity level in the operating room is normal and the rivers do not flow, the mount still rusted over time. The whole blame is natural humidity. Not only does such a hardware gradually lose strength, but even if necessary, it is difficult to disassemble a piece of furniture and remove the nut from the bolt - it tightly “clings” to the thread, and it is almost impossible to remove it, and even in an inaccessible place. This problem has long been eliminated - today's bolts do not corrode, as they are made of the following materials:

- stainless steel with a galvanized coating of white or yellow color, bolts with an additional chrome coating are less common;

- brass and copper bolts are less common, more expensive;

- hard plastics.

The vast majority of furniture bolts are made of galvanized stainless steel. In the marking, the manufacturer must indicate the used steel grade:

- A2 (domestic analogue - 08X18H10) is an excellent material that is not subject to corrosion, almost does not magnetize, withstands temperatures from -200 to +4250FROM;

- steel A4 (10X17H13M2) in the composition has 2-3% molybdenum, due to which it is even more resistant to moisture and acids, so fasteners from this material are used even in aggressive environments. Bolts of class A2 and A4 come out of bolts of accuracy class A (more on that below);

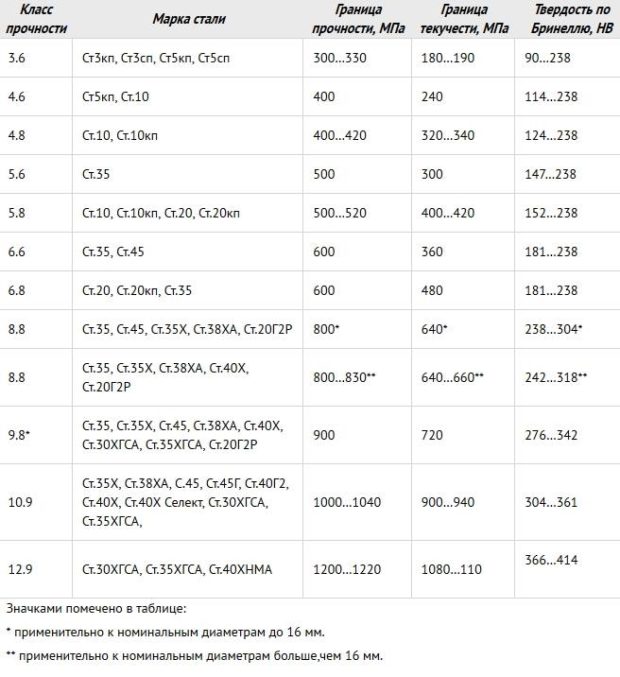

- other types of steels are used in production, for example, 38XA, 30KHGSA, 10KP, 20KP, 10KP, 20G2R, 10, 35 and others. Information on steel grades and strength is collected in the table.

No. 5. Strength class

The steel grade and the features of its processing determine the strength class of the finished product. According to regulatory documents, 11 strength classes are determined, here are some of them: 3.6, 4.6, 5.6, ..., 10.9, 12.9. Deciphering these numbers is easy:

- the number before the decimal point (point) indicates the tensile strength, N / mm2. We get the exact value if we multiply the number by 100. For a bolt of strength class 4.6 it will be 4 * 100 = 400 N / mm2;

- the decimal point is the ratio of the yield moment to tensile strength, expressed as a percentage. For the same bolt 4.6, this parameter will be 60%. The yield strength is considered to be such a load that causes irreversible deformation of the product.

In the furniture industry, bolts from class 4.6 to 12.9 are used. The most popular were the hardware classes 4.6, 5.6, 5.8, 6.6 and 6.8. However, if you have to fasten critical parts, you need to use bolts 8.8. They are called high strength. In general, all fasteners that withstand 800 N / mm2 and more, called high strength. Furniture bolts of even higher strength are much less common and more expensive.

Bolts of low strength are made, as a rule, by turning. For more durable products, volumetric stamping is used, and the most durable are also hardened.

No. 6. Accuracy class

Three accuracy classes are defined by standards: A, B and C. For each class there are manufacturing tolerances, each class is distinguished by the roughness of the thread, the difference in the diameter of the rod and the bearing surface of the head.

- Bolts class C used when making connections that do not require calculations. This is the most popular type of bolt in the furniture industry. Such fasteners are installed in the hole, which is 2-3 mm larger than the diameter of the rod. If you apply some effort to the parts connected in this way, you will notice small movements caused by the difference in diameter.

- Bolts class B put in the holes 1-1.5 mm larger than the diameter of the rod, so when calculating and creating holes requires a more serious approach;

- Bolts class A are performed with the most accurate geometry and are installed in holes created exactly for their diameter (only 0.25-0.3 mm more). Such fasteners are created only by turning, which ensures high strength and excellent accuracy. Only one minus is the cost.

Number 7. What else to consider when buying?

It is probably unnecessary to explain that the durability and reliability of the furniture made will depend on the quality of the bolts. Nobody wants to be on the floor in the middle of the night because the bed was assembled with bad bolts. And you don’t want anyone to fall from a chair or ladder. It is impossible to be 100% sure of the reliability of the future fastening, but you can evaluate some parameters of the bolt, which will indicate its quality:

- fasteners that are not susceptible to corrosion are made by galvanizing. If you twist such a hardware in your hands and scratch the coating a little, there will be no trace left on your hands. If the manufacturer cheated and coated the product with silver paint (for galvanizing), then there will be traces of coating on his hands;

- pick the nut of the required size and try to screw it onto the bolt. If the process went without any difficulties, then the manufacturer released a quality product with good geometry;

- Choose only reliable and reputable stores that will not risk your reputation.Ask for certificates of conformity for the goods - a normal manufacturer will have all the documents.

In conclusion, we note that if you are not completely sure that you can choose the right furniture bolts yourself, it makes sense to use the help of a professional, and in the future you yourself can distinguish high-quality hardware from low-quality.