How to choose a concrete mixer

The question of choosing a concrete mixer is before everyone who has started an independent more or less large-scale construction. Choosing this, at first glance, not the most difficult tool is not so simple, because even experienced builders do not always know all the subtleties. The choice of a concrete mixer will determine how comfortable the work with it will be, how fast and productive the construction will be, and how high-quality the finished building will be. concrete mortar. For each specific case, a different type of concrete mixer is suitable, which may differ in principle of operation, technical characteristics, volume, type of engine, etc.

It is immediately worth noting that in many respects the quality of the concrete mixer depends on the manufacturer and seller: if they value their name, they will only sell reliable products. You can apply for the purchase of such a tool in a specialized store or in an online store.

The principle of operation and type of device

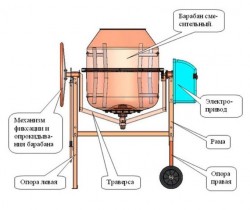

Concrete mixers are popularly called concrete mixers. Their design is not very complicated, and consists of several key elements: bed with or without chassis, concrete mixing tank, power unit with transmission and unloading mechanism.

Concrete mixers are popularly called concrete mixers. Their design is not very complicated, and consists of several key elements: bed with or without chassis, concrete mixing tank, power unit with transmission and unloading mechanism.

Bed combines all the elements and nodes in a single design, it consists of pipes, profiles and is often supplemented by one or two pairs of wheeled chassis for ease of movement of the entire device. Transmission and Power Block - a place where electrical energy is converted into rotational movements necessary for the preparation of concrete mortar. IN working capacity the process of mixing all the components to obtain concrete. This capacity may have a different volume, which will determine the scope of use. Located in it kneading organs, which can have different shapes, different operating principles, and often they are combined with other structural elements.

Bed combines all the elements and nodes in a single design, it consists of pipes, profiles and is often supplemented by one or two pairs of wheeled chassis for ease of movement of the entire device. Transmission and Power Block - a place where electrical energy is converted into rotational movements necessary for the preparation of concrete mortar. IN working capacity the process of mixing all the components to obtain concrete. This capacity may have a different volume, which will determine the scope of use. Located in it kneading organs, which can have different shapes, different operating principles, and often they are combined with other structural elements.

Unloading mechanismdesigned to extract the finished concrete can be implemented in different ways: worm or step gears, a special shutter that opens the part of the bottom of the drum, when necessary, etc.

By type of drive All concrete mixers can be divided into the following types:

muscular drive. These are the simplest and most ancient devices, where the power source for mixing concrete is human power. The muscular energy of a person, by acting on a certain lever, turns into rotational movements of the concrete mixer. Such devices are characterized by the simplest structure, reliability, low cost and autonomy. But they do not free a person to perform other tasks, they require the application of enormous energy, and the volume of the drum cannot exceed 100 liters, otherwise it will be impossible to mix the solution;

muscular drive. These are the simplest and most ancient devices, where the power source for mixing concrete is human power. The muscular energy of a person, by acting on a certain lever, turns into rotational movements of the concrete mixer. Such devices are characterized by the simplest structure, reliability, low cost and autonomy. But they do not free a person to perform other tasks, they require the application of enormous energy, and the volume of the drum cannot exceed 100 liters, otherwise it will be impossible to mix the solution;- hydraulic and pneumatic drive used only in industrial environments. Here the source is a large pressure of water or air, which acts on the gear motor. Such concrete mixers turn out to be very powerful, require strict safety precautions and can be used in places with developed energy infrastructure;

- motor drive involves the use of an internal combustion engine.The main advantage of such concrete mixers is autonomy, but they still have not gained distribution due to the high cost, noise and the appearance of toxic exhaust gases;

electric drive. They are now equipped with 99% concrete mixers, this is the most convenient, thought-out way to get energy today. Very tiny household concrete mixers and huge industrial devices with a capacity of several cubic meters are powered by electricity.

electric drive. They are now equipped with 99% concrete mixers, this is the most convenient, thought-out way to get energy today. Very tiny household concrete mixers and huge industrial devices with a capacity of several cubic meters are powered by electricity.

According to the principle of work concrete mixers can be:

- gravitational. They are intended for the preparation of viscous and tough compositions. The prepared mixture inside is thoroughly mixed thanks to the blades of a special structure, which do not allow the composition to accumulate on the walls: the blades themselves remain motionless, and only the drum rotates. The maximum drum volume in such concrete mixers is 300 liters, and they are great for private independent construction. All components are loaded into the drum manually, with the exception of some advanced models;

- forced They are used for production purposes, they are large, so it is not advisable to use such devices for individual construction. Such concrete mixers are great for preparing solutions that contain a large amount of water, but they are completely unsuitable for mixtures with large particles. Mixing here is due to rotating arachnid lobes.

Gravity concrete mixers may also differ in the type of device:

- crowned - the most popular devices where the mixing of the solution is due to a special crown, which can be made of steel, cast iron or plastic. It is better to give preference to cast-iron options, which are many among Elitech concrete mixers. Polyurethane crowns are also in demand, which are as good as cast iron, but the noise level during their operation is much lower. Steel crowns are the most reliable, but also the most expensive, perfect for the largest construction projects, and for individual construction you can choose the simpler option. Coronal concrete mixers are very easy to repair, they are relatively inexpensive, which brings them wide popularity;

- gear concrete mixers are more reliable and durable. Although it’s difficult to repair them, they break much less often than coronal ones.

Specifications

Drum volume

The volume of the concrete mixer drum is one of the key indicators to consider when choosing. You need to build on what work needs to be done, and how much concrete mix is needed for this. So, for construction pergolas and the construction of a multi-storey building, the volume of concrete, and, accordingly, the drum of the concrete mixer will be different.

The volume of the concrete mixer drum is one of the key indicators to consider when choosing. You need to build on what work needs to be done, and how much concrete mix is needed for this. So, for construction pergolas and the construction of a multi-storey building, the volume of concrete, and, accordingly, the drum of the concrete mixer will be different.

If it is necessary to carry out repairs, build a garage, a bathhouse or other simple small object, then a volume of 100 liters should be enough, while the weight of the concrete mixer will be from 20 kg. If you plan to build a small one-story house, then for more efficient and faster work it is better to purchase a concrete mixer with a volume of up to 150 liters. Even more capacious devices will be needed when you need to build buildings in several floors. In this case, the drum volume can reach 300 liters. Bulk concrete mixers are already useful for the construction of multi-storey buildings and are not used in independent construction.

For example, if you need to build barn, then you can safely buy a concrete mixer for 55-60 liters, but if you need to build a house, and at the same time a team of builders of 4-5 people will work, then it is better to pay attention to devices with a volume of 150-190 liters. It is important not to overload the drum so that the concrete mixer does not fail. Some modern models are already equipped with an overload sensor and, with any signs of overheating, they simply stop the operation by giving a signal.

Engine power

Choosing a concrete mixer, many try to purchase a device with the most powerful engine possible, but this desire, unfortunately, does not live up to expectations. As a result, a powerful engine only costs more when buying and servicing, as it consumes a lot of electricity, and the network also overloads.

Choosing a concrete mixer, many try to purchase a device with the most powerful engine possible, but this desire, unfortunately, does not live up to expectations. As a result, a powerful engine only costs more when buying and servicing, as it consumes a lot of electricity, and the network also overloads.

The most powerful engines will be needed for serious large-scale work, and for domestic purposes, you can use simpler options with a power of up to 1 kW. Someone might be surprised, but for a concrete mixer of 130 liters, a 700 W engine is enough. At first glance, this is a ridiculous figure, but the experience of many builders suggests that this is the optimal value.

Mode of operation

Concrete mixer depending on working conditions They are divided into two groups:

- concrete mixers with periodic operation. These devices are designed for the construction of small facilities or for repair work, and the peculiarity is that periodically such concrete mixers need to be suspended, otherwise the resource of some elements will quickly be exhausted, and the device itself will become worthless. Such concrete mixers are perfect for work in the country, in a country house, etc .;

- continuous concrete mixers - more powerful and complex devices, which, as the name implies, can prepare concrete without interruptions, but you have to pay for it: they cost much more than the first type. Such units are used on large construction sites, where work is carried out in several shifts, and delaying and stopping is simply impossible.

Voltage

More powerful concrete mixers, which are designed to prepare a solution in large volumes, are usually equipped with a three-phase motor, which should receive energy from a three-phase current diesel generator. As a result, the maintenance of all this flies a pretty penny and is justified only if a large object is being built.

More powerful concrete mixers, which are designed to prepare a solution in large volumes, are usually equipped with a three-phase motor, which should receive energy from a three-phase current diesel generator. As a result, the maintenance of all this flies a pretty penny and is justified only if a large object is being built.

For individual construction, it is better to choose a device that can be powered from a 220 V network: the power will be small, but a concrete mixer of this type will cope with its task with a bang.

Drum type

Concrete mixer drum can be welded or seamless. In the first case, specially cut steel plates are used, which are then reliably welded. The wall thickness of such a drum can reach 4 mm: the thicker they are, the more reliable the device, because some frozen pieces of concrete will have to be beaten off with a chisel.

Concrete mixer drum can be welded or seamless. In the first case, specially cut steel plates are used, which are then reliably welded. The wall thickness of such a drum can reach 4 mm: the thicker they are, the more reliable the device, because some frozen pieces of concrete will have to be beaten off with a chisel.

Seamless drums are made in special deep-drawing presses, and the result is a beautiful, one-piece product with wall thicknesses up to 2 mm.

You can check the thickness of the walls not even by eye, but by cotton: the more deaf the sound, the thicker, and therefore reliable, the walls in it.

Seasonality of work

It is better to work with concrete in the warm season, since in winter its performance deteriorates. Therefore, most concrete mixers are designed to work in spring and autumnwhen the conditions for construction are optimal. But in some regions, low temperatures can be kept for a very long time, and concrete mortar may be urgently needed in the winter. Some manufacturers have already responded to this problem and began to produce special concrete mixers that are able to work in winter and at the same time improve the performance of concrete prepared in the cold season.

Manufacturer

Among the concrete mixers are many options from foreign and domestic manufacturers. Experts recommend choosing devices made in Germany, France and Italy - they are of high quality, reliability and durability. Also, Polish and Croatian models have proven themselves quite well, which are slightly cheaper, but they are inferior in quality quite a bit.Nevertheless, when choosing a particular unit, you need to rely not only on your own intuition, the words of the consultant, but also on reviews of a particular concrete mixer, which you can find an infinite number of on the network.

Which manufacturers have proven themselves in the best way?

Guy Noel - one of the most popular concrete mixers in the domestic market. They are perfectly balanced in price and quality, and their main advantage is still the cost. Moreover, they are not without several minor drawbacks, for example, the not-so-well-designed mechanism for tilting the drum, they also have thin blades, and under high loads they can be deformed. But all these disadvantages are not so significant, which explains the wide distribution of devices from this manufacturer;

- Limex - the best concrete mixers in the average price range. The trust in them of thousands of users is justified by high quality and reliability. Their most important advantages include a convenient and well-designed mechanism for tilting the drum, ease of replacing the bearing. The company's specialists are constantly working on improving their products, and now, for example, all concrete mixers are equipped with a special mechanism that prevents the motor from burning out when the drum is jammed;

Altrad - Polish concrete mixers, presented in a huge assortment, but because of their characteristics, you need to adapt to them, and then you can extract solid pluses. The first advantage is a low price, the second is relatively thick blades, so their deformation is almost impossible. But the drum tilt mechanism is not the strongest side of most models, and it is often uncomfortable and fails after a while. Otherwise, these concrete mixers are convenient, practical and reliable.

Some operating tips

Any concrete mixer can quickly fail if used improperly. Therefore, you must be extremely careful not only about the choice of device, but also about its operation.

It is necessary to clearly follow all the rules described in the instructions of the device. It is advisable to check before starting work concrete mixer serviceability at idle, and only then proceed with the preparation of the solution. And in order to prepare concrete, first add water, and only then the remaining components: sand, crushed stone and cement. Better not to use crushed stone with a size of more than 40 mm, therefore, before preparing concrete it is better to sift it. The instructions for the device should indicate when temperatures it can be operated: more often it is a range of 3-400C, but there are concrete mixers that are equipped with a mixture heating system and function normally in the cold, as mentioned above.

If there are gear gears in the concrete mixer, they should never be lubricated with oil, otherwise the adhesion of the particles of the solution will lead to the rapid failure of the entire device. It is important during the operation of the mechanism not to cover it with jackets, rags, rags, etc., since this delays the flow of air, can lead to overheating and even damage.

If there are gear gears in the concrete mixer, they should never be lubricated with oil, otherwise the adhesion of the particles of the solution will lead to the rapid failure of the entire device. It is important during the operation of the mechanism not to cover it with jackets, rags, rags, etc., since this delays the flow of air, can lead to overheating and even damage.

It is better to connect the concrete mixer to the network using a special euro cable, which is used for lawn mowers and washing machines. This is necessary to avoid the influence of voltage fluctuations on the operation of the concrete mixer. Also, when the case is solidly heated, it is strictly forbidden to cool it with water. Naturally, during operation, hands cannot be thrust into the concrete mixer, and immediately after preparing the mortar, it must be removed so that in the future it does not have to be literally gnawed out of it.

Experts advise lubricating the drum with special mineral oils to facilitate care of the device. There are also special tools that can reduce the adhesion of the solution to the walls of the drum and even those that contribute to the destruction of the already formed stone.

When buying, it is better to clarify the product warranty and, just in case, purchase the most wearing parts: crown, drive belt, gear.

electric drive. They are now equipped with 99% concrete mixers, this is the most convenient, thought-out way to get energy today. Very tiny household concrete mixers and huge industrial devices with a capacity of several cubic meters are powered by electricity.

electric drive. They are now equipped with 99% concrete mixers, this is the most convenient, thought-out way to get energy today. Very tiny household concrete mixers and huge industrial devices with a capacity of several cubic meters are powered by electricity.

There was a dispute - you need / you can lubricate the gear. The opponent says that it’s necessary - there will be less rattling and less wear, and I say that it’s impossible, since garbage will stick to the grease, it’s still open, and it will only get worse. Who is right in your opinion?