Knitting reinforcement: tools, materials, methods and patterns of knitting

The key to reliability and durability of any building is foundation. Even the strongest walls without a normal foundation will gradually collapse, and so that it is durable, usually use reinforcement. But it also needs to be connected correctly so that in the end a strong structure is obtained that can withstand the weight of the entire building. That is why the process of knitting reinforcement requires special attention and a careful approach.

In order to create a solid foundation for foundation, individual metal rods can be welded. But now they resort to this method much less often than to knit for a number of reasons.

In order to create a solid foundation for foundation, individual metal rods can be welded. But now they resort to this method much less often than to knit for a number of reasons.

At first, with independent construction, the welding process, as a rule, is impossible, because few people know perfectly all the subtleties and nuances of this business, so it is much easier to turn to knitting. Moreover, it also turns out much faster.

Secondly, in the places of welding, oxidative processes can gradually begin to develop, which means that the weld will become not so strong, and the foundation will lose some of its reliability. When knitting reinforcement, the risk of corrosion is significantly reduced, which becomes another advantage of this method.

Thirdly, during welding, especially abnormal, the metal structure is violated, which does not very well affect the final quality of work. If the reinforcement is knitted correctly, then the foundation, lintels and other reinforced concrete structures will be reliable and durable. But the emphasis here must be made precisely on the correctness of the work.

Materials for knitting reinforcement

To knit reinforcement, you must first buy everything you need. First of all, it’s itself fittings: steel rods of a certain diameter and length are used. The reliability and strength of the finished foundation directly depends on the thickness of the reinforcement, and there should not be less than 6 mm in the diameter of the rod. In length, basically, all rods are standard - from 6 meters. It is better to purchase fittings with delivery: this is convenient and will save the effort and time spent on the construction of the foundation. Also pay attention to the surface of the reinforcement, because there are smooth products, but there are rods with notches, ridges, corrugation. The latter are characterized by better adhesion with concreteTherefore, in the end, a stronger construction is obtained.

To knit reinforcement, you must first buy everything you need. First of all, it’s itself fittings: steel rods of a certain diameter and length are used. The reliability and strength of the finished foundation directly depends on the thickness of the reinforcement, and there should not be less than 6 mm in the diameter of the rod. In length, basically, all rods are standard - from 6 meters. It is better to purchase fittings with delivery: this is convenient and will save the effort and time spent on the construction of the foundation. Also pay attention to the surface of the reinforcement, because there are smooth products, but there are rods with notches, ridges, corrugation. The latter are characterized by better adhesion with concreteTherefore, in the end, a stronger construction is obtained.

Metal rods are connected either with a wire or with plastic clamps. And it is the quality of these connecting elements that directly affects the integrity and strength.

Wire for knitting fittings it is selected with a round cross section and a diameter of 1.2-1.4 mm: if you take a thinner one, it will not cope with the load, and if a thicker one, it will be difficult to bend. Annealed steel wire, which is usually sold in bays, is excellent for this purpose. It easily bends, quickly takes the desired shape, but at the same time it is characterized by high strength and durability. It is better not to use unbaked wire for these purposes, it is much more difficult to work with it: it is difficult to bend it, it often breaks, but if necessary it can be turned into baked wire. So, just hold it over an open fire, and then leave it to cool in air for half an hour.

Wire for knitting fittings it is selected with a round cross section and a diameter of 1.2-1.4 mm: if you take a thinner one, it will not cope with the load, and if a thicker one, it will be difficult to bend. Annealed steel wire, which is usually sold in bays, is excellent for this purpose. It easily bends, quickly takes the desired shape, but at the same time it is characterized by high strength and durability. It is better not to use unbaked wire for these purposes, it is much more difficult to work with it: it is difficult to bend it, it often breaks, but if necessary it can be turned into baked wire. So, just hold it over an open fire, and then leave it to cool in air for half an hour.

For knitting need pieces of wire 25-30 cm long: it is not very convenient to cut or bite off the necessary piece each time, so experienced specialists recommend folding the wire several times, observing the length required for the work, and then simply grinder cut the fold points. Thus, in a few minutes all the elements will be ready, and you will not have to be distracted by constant cutting.

Now more and more popular plastic clampsHowever, many builders remain conservative and do not trust this method of fastening. Nevertheless, the use of clamps provides reliable fixation of the reinforcement, but is also associated with many subtleties. So, the "bare" frame does not withstand dynamic loads, and if it is incorrect to step on the upper elements of the entire structure during assembly or to fill it with concrete incorrectly, some fasteners may not withstand and crack. With special care, it will be necessary to use vibration equipment when compacting concrete. The obvious advantage of plastic clamps is the simplest process of their use, because it is enough just to tighten the clamp properly at the junction of two rods, and this can be done quickly and easily.

Now more and more popular plastic clampsHowever, many builders remain conservative and do not trust this method of fastening. Nevertheless, the use of clamps provides reliable fixation of the reinforcement, but is also associated with many subtleties. So, the "bare" frame does not withstand dynamic loads, and if it is incorrect to step on the upper elements of the entire structure during assembly or to fill it with concrete incorrectly, some fasteners may not withstand and crack. With special care, it will be necessary to use vibration equipment when compacting concrete. The obvious advantage of plastic clamps is the simplest process of their use, because it is enough just to tighten the clamp properly at the junction of two rods, and this can be done quickly and easily.

Rebar Knitting Tools

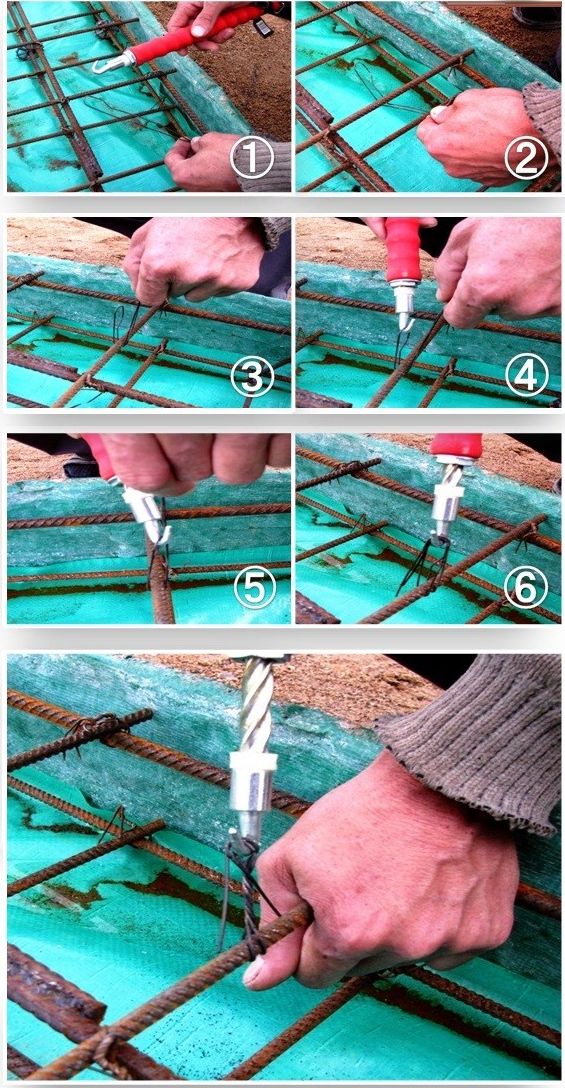

Of course, you can knit the wire with your hands, but the process will be simpler, faster and more effective if you use special tools for this. So, you can use crochet hook: There are plenty of them in hardware stores, and buying them is not a problem. You can find both the most ordinary models, as well as screw and semi-automatic hooks: although they facilitate the work, they still require the application of physical force, even if not to rotate the hook, but to twitch the tool. Many professionals say that store hooks are not always convenient, they are short, and they quickly rust, therefore they advise making such a tool for yourself: in the end, you can save money and make the future knitting process more convenient. For this, a piece of corrugated reinforcement may be needed, and a bearing can be mounted in the handle to make it easier to work. For these purposes, a nail that can be used as a nozzle for screwdriver.

Of course, you can knit the wire with your hands, but the process will be simpler, faster and more effective if you use special tools for this. So, you can use crochet hook: There are plenty of them in hardware stores, and buying them is not a problem. You can find both the most ordinary models, as well as screw and semi-automatic hooks: although they facilitate the work, they still require the application of physical force, even if not to rotate the hook, but to twitch the tool. Many professionals say that store hooks are not always convenient, they are short, and they quickly rust, therefore they advise making such a tool for yourself: in the end, you can save money and make the future knitting process more convenient. For this, a piece of corrugated reinforcement may be needed, and a bearing can be mounted in the handle to make it easier to work. For these purposes, a nail that can be used as a nozzle for screwdriver.

An alternative to hooks and all homemade products - rebar knitting gun. This device, which greatly simplifies and automates the entire process and will become simply indispensable when it comes to large-scale construction. The device itself twists the wire with the necessary strength and to a certain extent in record time - 0.8 s. In addition, such devices weigh a little, so the second hand can be free, it can hold the mount. Depending on the diameter of the reinforcement, a specific model of the gun is selected, and the modern assortment allows you to choose equipment for any diameter of steel rods. Due to the high cost of this unit, it makes sense to buy it only to large construction companies.

An alternative to hooks and all homemade products - rebar knitting gun. This device, which greatly simplifies and automates the entire process and will become simply indispensable when it comes to large-scale construction. The device itself twists the wire with the necessary strength and to a certain extent in record time - 0.8 s. In addition, such devices weigh a little, so the second hand can be free, it can hold the mount. Depending on the diameter of the reinforcement, a specific model of the gun is selected, and the modern assortment allows you to choose equipment for any diameter of steel rods. Due to the high cost of this unit, it makes sense to buy it only to large construction companies.

At home, you can create an alternative to a gun for knitting reinforcement and convert a conventional screwdriver for this: drill not suitable due to the higher rotation speed. A kind of knitting hook is inserted into the tool holder, which can be made independently from a wire with a cross section of 4 mm, a thick chopped off nail, a piece electrode etc. You don’t have to do anything with your own hands - just press the button and hold the tool firmly.

At home, you can create an alternative to a gun for knitting reinforcement and convert a conventional screwdriver for this: drill not suitable due to the higher rotation speed. A kind of knitting hook is inserted into the tool holder, which can be made independently from a wire with a cross section of 4 mm, a thick chopped off nail, a piece electrode etc. You don’t have to do anything with your own hands - just press the button and hold the tool firmly.

With a gun, knitting reinforcement is 5-7 times faster than using a hook, but this method also has its drawbacks. It is very poorly suited for hard-to-reach places, consumes more wire and needs regular recharging of the battery or connection to the electric network.

Methods and schemes of knitting reinforcement

First of all, it is necessary to prepare all materials for installation, transfer them to the installation site, if necessary, align the fittings and place plastic clamps under it, which are placed between the fittings and the formwork and are necessary so that certain parts of the fittings do not stick out from under concrete. Now you can produce a bunch. Reinforcement can be knitted in several ways, depending on the tools and materials used.

So, if self-tightening is used for knitting plastic clamps, then no questions can arise here in principle, and most importantly, it’s good to tighten them. Even simpler is the case with the gun, which he does everything in literally an instant. The most complex and time-consuming is the process of knitting reinforcement with a wire and hook: several basic methods and techniques are used.

Today, there are many options for knitting reinforcement, which differ in where the wire is bent. In principle, in terms of reliability and strength, all options are almost the same, and everyone can choose the technique that is most convenient for him.

Method number 1

The simplest and most common option, which includes this sequence of actions:

- fold the length of wire twice;

- we conduct a wire for reinforcement, in the place of connection of two rods;

- thread the hook into the loop of the wire;

- with the fingers we pull the free end of the wire to the hook and impose on it, slightly bending;

- we begin the rotational movements of the hook, twisting both ends of the wire;

- after 3-5 turns, when the connection is securely fastened, you can get the hook out of the loop.

Method number 2

The process has much in common with the previous one, but it is still slightly different:

- fold the wire in half and put it under the armature, at the desired connection point;

- hook up the loop;

- we bend the second end through the hook so that in the end an O-shaped loop is formed;

- twist the resulting loop until a reliable twist is achieved, and after that we pull out the hook.

Method number 3

According to many experts, this particular method is the most convenient, since it frees one hand:

- we start the wire under the reinforcement;

- insert the hook into the loop and pry the second end of the wire with it;

- bend the wire down;

- pull the hook onto yourself, twist it several times, and you're done.

Method number 4

- again we fold the wire in half and start under the reinforcement;

- we carefully press it to the rod, and bend the ends onto ourselves;

- insert the hook, make a few turns and get the hook.

This method allows you to get a more reliable twist. The most experienced craftsmen advise bending the wire before twisting so as not to make many revolutions, because reliability will not increase, but there is a chance that the wire will simply break. The optimal number of revolutions is 3-5.

As you can see, all methods are very similar, and differ only in nuances. If you need to knit reinforcement with your own hands, then after several attempts you can get used to and choose the best option for yourself. Some masters say that the process of hand knitting is simplified if you use screw hooks, but this is a matter of technique and habits.

In conclusion

Knitting reinforcement - although not the easiest task, but, in principle, is quite feasible even by the most inexperienced master. You just need to stock up on the necessary tools, choose the appropriate knitting method and proceed with the actions. Of course, using plastic clamps is the easiest and cheapest, and a special knitting gun is even faster, but it will cost a lot, so many still use a special hook: it’s not difficult to work with it, but with some skill strong connections are obtained.

Hello. I’m doing a foundation under a doghouse, do I need fittings for such a small volume?

Personally, in my opinion, it is not necessary if we are of course talking about a booth of normal size, for a dog, and not for an elephant. Your foundation will not experience any significant loads. But to calm the soul - you can throw a few pieces of reinforcement, wire or other scrap metal.