Preparation of metal for painting - removal of traces of corrosion and clogging

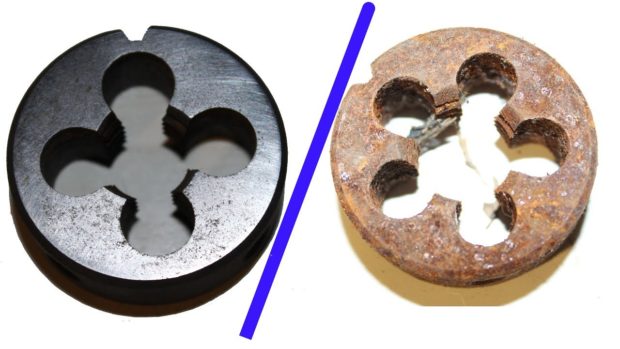

We are used to considering metal as the most durable and strong material, but, alas, even it has a weak spot, and its name is corrosion. The easiest way to protect yourself from it is to coat the metal with a paint coat. But what if the rust has already hit the metal? Then, before painting, you will have to pay attention to the proper preparation of the metal for painting and removal of corrosion from its surface.

The technology consists of two stages - preparation and application of paint material. The quality of these works directly affects the subsequent operational period. That is why the cleaning of metal from corrosion and dirt is an important point for maintaining the durability of the metal structure. Consider the most effective ways to remove rust from metal before painting.

How does corrosion manifest itself?

Scientists have found that about 10% of metal products per day "dies" from corrosion. One can argue with this figure, but if you look around, you can easily find rust spots on the mixer, fence, window grill, car and other items. If no action is taken, then corrosion will quickly destroy the metal. And if rusty mixer change is not a problem, then corrosion on industrial equipment and critical structures can lead to irreparable results.

Surfaces that often come in contact with a liquid or are exposed to high temperatures suffer most from rust. Sometimes rust develops even under a paintwork as a result of damage that is invisible to humans, but, as a rule, the foci of corrosion are clearly visible and represent individual points and spots of brown color. Iron oxides give a specific color. Specialists distinguish such rust damage to metal:

- corrosion spots - they are characterized by a shallow depth, and development begins in width;

- pitting corrosion - small dots penetrating deep inside. If you do not interfere with their development, through holes will appear in the material;

- through - a complete defeat that destroys the structure of the part;

- sub-film - the center of the spread of rust is under a layer of paint, which eventually begins to swell. It happens that such corrosion does not manifest itself at all until the metal is completely destroyed. Such damage is the most dangerous, because it is an invisible enemy.

How to protect metal from corrosion? You just need to apply high-quality paint, varnish or other protective coating, periodically update it. Many make the mistake of spraying paint over the hotbed of corrosion. and hoping that the affected area does not grow. The adhesion of the paint to a loose rusty surface is low, so that the paint will crack in the near future and make the metal structure vulnerable. That is why before painting it is worth removing all traces of corrosion, and with them all types of bites and old layers of paint. The old coating can not be a quality basis for the new, therefore it should be disposed of immediately.

How can corrosion be removed from metal?

Mankind has come up with many ways to remove traces of rust from a metal surface. Professional methods include:

- mechanical;

- chemical;

- thermal.

In addition, there is a number of home methods based on chemical reactions and mechanical removal of damage.

The tool is selected on the basis of what scale corrosion has reached and what damage it has caused. If rust has just “attacked” the product, then it may be possible to cope on its own, using improvised means. On a large scale and to obtain a more effective result, it is better to resort to the use of professional tools and not try to fight rust at home in order to avoid the risks of decomposition.

Mechanical cleaning

The mechanical method is considered laborious, but gives excellent results. Cleaning takes place with a manual or mechanized tool. Emery paper, wire brushes, grinding machines, as well as abrasive compounds based on sand, or sand with water are used. As a result, it is possible to achieve a rough surface, which is characterized by high adhesion to the paint.

The following tools are used for mechanical cleaning:

- Pwire brushes. These are special tools with a fairly rigid base. With the help of human strength, under pressure, they affect a steel product, as if scraping off traces of decomposition from it. Basically, they resort to it to eliminate small foci of corrosion, as well as for stripping welds at primary finish. The method does not allow to achieve high quality cleaning, because the brushes do not remove the scale. In addition, a large amount of dust is generated in the process;

- grinding discs. This is a much more effective way that allows you to remove all rusty deposits. The method is suitable for small defects and is used during restoration work. If there are loose layers, then it is better to remove them manually, and only then take on the grinding discs. Decent results will be obtained if you use high-quality grinding wheels. True, this method also has some disadvantages. It will require expensive consumables and certain skills to work with the tool;

- sandblasted the damaged surface is treated with sand or other abrasive, which, under high pressure, enters through the tube outward, acts on the surface, completely cleansing it of rust and dirt, even in the most inaccessible places. The advantage is that both river and construction are taken for sandblasting sand microparticles (particle size and shape may vary depending on technology and installation), moreover, they can be easily reused. However, with the second use of the same sand, the processing efficiency decreases, and the amount of dust increases.

- gabrasive stripping (waterblasting) uses a similar principle, but cleaning in this case occurs under a powerful stream of water and sand. Processing can occur at different pressures. Ultrahigh pressure (more than 1700 atm) is used when it is necessary to completely remove all traces of heavily stubborn rust. At high pressure (700-1700 atm), most of the rust and paint are well removed, minor traces may remain, which also go away with a longer treatment. Cleaning at a pressure of 350-700 atm allows you to get rid of the old layer of paint, dirt and part of the rust, but magnetites will still remain on the surface. Processing at pressures up to 350 atm is used mainly for preliminary cleaning of the surface, removing dirt, peeling paint. Cleaning at a pressure of 6-8 atm allows for the most economical use of abrasive, reduces the level of dust formation, but secondary cleaning may occur after cleaning. Hydroabrasive cleaning is considered difficult, a similar installation is not easy to build, and only professional, experienced specialists should work with it.

After machining, a rust transducer is applied to the metal surface. When it dries, evaluate the result. If there is still rust, then re-treatment is carried out. All work is carried out in personal protective equipment: clothing, glasses, a respirator.

Chemical stripping

Solution pickling is one of the best options because rust breaks down under the influence of chemically active substances. The compositions are applied using brushes or by spraying. They can conditionally be divided into two categories:

- fromwashable substance They work efficiently, they must be washed off with water after the reaction, and when exposed to the surface of the water, new foci of rust will appear. Therefore, after washing with the product, the element must be thoroughly dried and covered with an anti-corrosion layer;

- nwashable, the so-called soil converters. The reaction product of the agent and rust can hardly be called a full-fledged soil, but it does not need to be washed off with water, but this is a big plus.

The chemical method allows you to remove not only rust, but also various kinds of pollution. For this, various washes and solvents:

- a good rust remover is 5% water solution of sulfuric or hydrochloric acid. But an inhibitor is added to them, which can slow down the reaction. It is important to understand that it is categorically not recommended to use acids without it, since this can damage not only steel, but also adversely affect the human body. Urotropin is added to hydrochloric acid; phosphoric - tartaric acid or butyl alcohol;

- severely affected surfaces are treated a mixture of lactic acid and liquid paraffin. Under the influence of acid, rust turns into iron lactate, which, like salt, is easily dissolved by liquid paraffin. At the end of the work, the part is wiped with a rag.

Even more effective cleaning can be achieved with electrochemical methodbut for its implementation sophisticated industrial equipment and special conditions will be required.

Heat treatment

This method involves exposure to rusty formations of extreme temperatures. Used for this oxygen acetylene burner, which eliminates almost all mill scale, but not all rust, with a strong flame. That is why today the method is used very rarely.

Sometimes used steam cleaning, which is supplied under a pressure of 100-120 atm. The option is not suitable for removing rust, but it copes with dirt perfectly, and the metal surface dries much faster than when treated with water, which reduces the risk of secondary rust formation.

How to remove rust at home?

If corrosion has not yet been bite into the metal, and the part or structure itself does not perform any critical tasks, then you can try to remove rust with improvised means. The ingenuity of the people allowed to develop several interesting and effective means:

- white vinegar able to dissolve rust, for this, the damaged part is immersed in vinegar for several hours, after which loose rust is cleaned mechanically. If the item is large, then vinegar is simply poured onto the surface. You can use aluminum foil, dip it in vinegar and use instead of a desk brush. Ordinary vinegar will do, but the processing time will increase to 24 hours. In some recipes white vinegar mixed with salt (1 tablespoon per 300 ml of vinegar) and flour, the remedy treats the damaged areas, then wash off;

- baking soda can be diluted with water to the consistency of liquid sour cream, so that the composition can be applied to the surface. Cleaning is carried out with a toothbrush, then the surface is rinsed;

- can be thorough sprinkle with salt damaged surface, then squeeze on it lime or lemon juice. Try to squeeze it as much as possible.Leave for 2-3 hours, and then clean the surface, for this you can use a brush or peel of lime;

- citric acid You can pour warm water into containers of the required size and place the damaged part there. The appearance of bubbles suggests that the process has begun. Leave the item for 8-10 hours, then rinse and dry;

- potatoes contains oxalic acid, which can act on rust. The method is suitable for very small foci, for example, for newly formed rust on a knife. Potatoes are cut in half, sprinkled salt and they clean the knife with it. You can attach potatoes to a rusty place for 15-20 minutes. Another variation of the method involves preliminary rubbing potatoes with laundry soap, after this, potatoes are applied to the hearth for a couple of hours;

- you can use it yourself oxalic acidJust remember to wear a protective mask, gloves and a bathrobe. Mix oxalic acid with warm water at the rate of 10 ml of acid per 100 ml of water. Dip the rust-affected item in the resulting solution for 20 minutes (it does not interfere with washing with detergent in advance), then clean it with a brush, rinse and dry;

- fish fat can dissolve rust if applied to damage and left for a couple of hours. Moreover, this tool will create a protective film on the metal;

- can be added to 300 ml of water 50 g caustic soda50 g ammonium250 g formalin (40%), dilute the product in 1 liter of water. Immerse the damaged part in the resulting solution for 15-35 minutes - the period depends on the degree of damage. Then the item is washed in hot water and wiped dry;

- diesel fuel also can handle rust. Take 1 liter of diesel fuel, put the rusted tools there, leave for a day, then clean them with a brush and wipe with a rag;

- there’s even a way that rust is treated ketchup, tomato paste and even Coca-Cola. Contrary to the seeming unreality of these methods, they work;

- allows you to cope with corrosion and means "Alkazeltser". A pair of tablets is dissolved in a basin with water, damaged parts are placed there. It remains to wipe and dry them;

- special phosphoric or oxalic acid in-store products very effective, but working with them is unsafe, so take care to protect the skin, eyes and respiratory tract. On the packaging of the product will be indicated instructions. Such substances are expensive. The most popular are Cinderella, Topperr and Furman;

- after cleaning the surface with a brush, you can apply a layer auto cleaner 3-4 mm thick and leave for several minutes, then rinse and wipe;

- sandpaper, steel brush-sponge, grinding machine - these mechanical cleaning devices can be used at home, however, they will require considerable effort;

- rust converter in the can will help to suspend the development of the corrosion process, can be used after processing by one of the above methods

How to evaluate the degree of paint removal?

Specialists in industrial conditions use standards to determine the degree of purification of a metal surface from corrosion. For Russia it is GOST 9.402, the international standard ISO 8501-1 is also used. At home, such an assessment is not carried out, but you still need to know something about it.

It is believed that even the most high-quality paint coat not able to protect metal from corrosion if its surface is poorly prepared:

- degree of preparation St1 - surface without preparation, the life of such a part is only 5-10% of the maximum possible;

- when brushing, the degree of preparation St2 is achieved, the service life is increased to 10-15% of the possible;

- when cleaning with other mechanical tools (St2-3), the service life will be 20-50% of the maximum;

- with chemical etching - 60-80%;

- when sandblasted (St 3) - 100%.

Painting materials

Before applying paint to a cleaned surface, it is better primer, but many modern compounds can do without a primer. For metal painting use such paints:

- epoxy based on silicone resins with hardener. High toxicity implies exclusively external use;

- oil - a traditional composition, before using which steel products are pre-coated with soil. The presence of a pungent odor requires staining in a well-ventilated area;

- alkyd - has good stability, does not require preliminary priming, can be applied in any conditions;

- acrylic - A modern type created on the basis of polymers. Not toxic, easy to use, needs careful preparation;

- rubber - perfectly protects roofs and outdoor elements subject to precipitation.

These are classic paint and varnish resources, which are found everywhere and are popular. However, there are other, more specialized mixtures:

- enamel applied specifically on rust, which impede its development;

- anticorrosive, not allowing the flow of moisture and oxygen;

- blacksmith, imparting wear resistance;

- toxic nitro paints.

All of them are able to provide additional protection, as well as improve performance and give reliability. All of these actions are an important part of preparing products for further painting and increase their lifespan.