6 tips for choosing building sand

Sand, in principle, and even more so in construction, is a very universal “tool”. It belongs to the category of sedimentary rocks and is mined in various ways: both natural and artificial, by crushing crushed stone or gravel. Sand really plays an important role, being part of all kinds of compounds and mixtures, and the quality of the building as a whole may depend on its quality.

The choice

For a different type and stage of construction work, different types of sand with different particle sizes and, as a result, their unique properties that will be useful in a particular application are needed. And, of course, choosing sand for these matters it is worth paying attention to a lot of criteria, which we will list below.

For a different type and stage of construction work, different types of sand with different particle sizes and, as a result, their unique properties that will be useful in a particular application are needed. And, of course, choosing sand for these matters it is worth paying attention to a lot of criteria, which we will list below.

So if you decide to do repair or if you don’t know what kind of sand is needed for your plans, you should read this article, in which we will analyze in more detail all the subtleties noted above and provide some useful tips on choosing sand for construction.

Types of sand

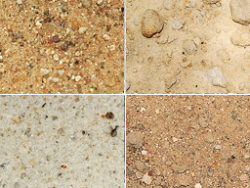

Before proceeding to the direct selection of sand for a start, it would be logical to consider several criteria that affect its use and quality. It’s best to start by classifying it by type, and basically, three types are most often distinguished:

Before proceeding to the direct selection of sand for a start, it would be logical to consider several criteria that affect its use and quality. It’s best to start by classifying it by type, and basically, three types are most often distinguished:

- ravine (or quarry);

- river;

- quartz.

All these types of sand have various features and qualities and somehow find their place in the application during construction.

Quarry sand

This type of sand, perhaps, The most common in construction and can be used at all its stages. It is a pretty good competitor to other types, as it ideally combines indicators such as price and quality. Moreover, its properties are practically not inferior to other species, with the exception, probably one single minus. This sand has very high levels of impurities, such as clay and other possible rocks, depending on the place of extraction. And despite this, it remains one of the most popular, used by many.

This type of sand, perhaps, The most common in construction and can be used at all its stages. It is a pretty good competitor to other types, as it ideally combines indicators such as price and quality. Moreover, its properties are practically not inferior to other species, with the exception, probably one single minus. This sand has very high levels of impurities, such as clay and other possible rocks, depending on the place of extraction. And despite this, it remains one of the most popular, used by many.

Due to this, it is not recommended for use in the construction of important elements, the main qualities of which are strength. However, such sand is perfect for adding foundation or building a canopy, as well as for various other purposes like concreting tracks or drainage and so on. On average, the particle size (the so-called fractions) is 0.7 mm. This indicator may also differ, given the area of production, as in the case of impurities.

There are also, if I may say so, improvements in the subspecies of quarry sand, namely washed. This is all the same sand, only better washed from various impurities, but this does not mean that it has become absolutely clean. Its strength, if it has increased, is not so much that it can be used for critical buildings. In this case, it would be better for you to pay in excess of a certain amount and buy more reliable sand.

Such sand, depending on the extraction, processing and the sieve installed on the processing equipment, can be, as small and medium or even large. It is worth paying attention to GOST, according to which in this sand there can be no more than 10% of gravel and up to 5% of other impurities.

River sand

As the name implies, this sand is mined from the bottom of rivers. At the same time, it is additionally washed, and its main advantage is an almost complete absence of any impurities and a high level of filtration. It also means that foundationmade with the addition of this type of sand has less drawdown and actively removes water from its structure.

As the name implies, this sand is mined from the bottom of rivers. At the same time, it is additionally washed, and its main advantage is an almost complete absence of any impurities and a high level of filtration. It also means that foundationmade with the addition of this type of sand has less drawdown and actively removes water from its structure.

It is best to use sand with large fractions for building walls, erecting columns and pouring the foundation under the bearing parts of the building. Usually it is mined in rivers with a fast current, which qualitatively leaches impurities in a short time period. And the water throughput, compared with the career option, is as much as 2 times higher.

It will not do without disadvantages. The main disadvantages of this type of sand are its higher cost in comparison with the previous version, as well as the “complexity” of production. The last drawback is not in the complexity of the process itself, but rather in the fact that, of course, not every village or nearby has rivers, and the cost of shipping can sometimes cost a considerable amount.

Quartz sand

While some resources and experts classify quartz sand as absolutely unsuitable for construction, others empirically prove in practice that this is not so. However, it is worth noting that this type of sand is mechanically mined and crushed pieces of rock. The consequence of this is that each such grain of sand has an increased, especially in comparison with other species, strength, as well as the mostred coefficient of impurities.

While some resources and experts classify quartz sand as absolutely unsuitable for construction, others empirically prove in practice that this is not so. However, it is worth noting that this type of sand is mechanically mined and crushed pieces of rock. The consequence of this is that each such grain of sand has an increased, especially in comparison with other species, strength, as well as the mostred coefficient of impurities.

From this we can draw the following conclusions. Firstly, this sand is best suited for the construction and erection of structures, the main parameter of which should be strength. It doesn't matter if it’s the foundation, concrete blocks or other types of buildings, quartz sand can make them stronger. The second important indicator may be greater porosity in contrast to river sand, which allows even more quickly to remove water from concrete.

Given the fact that this sand is a product of crushed rocks, it can have a different color, due to which it is often used as a “dye” for making concrete blocks. Minusit becomes a very high cost, since production costs are quite high, and there are not so many companies involved in this.

Particle size

The particle size index affects the strength, quality and removal of moisture from the mixture. Usually, when buying a particular type of sand, grain size is indicated in the documents, or in the product description. Basically, by this criterion The following groups are distinguished:

The particle size index affects the strength, quality and removal of moisture from the mixture. Usually, when buying a particular type of sand, grain size is indicated in the documents, or in the product description. Basically, by this criterion The following groups are distinguished:

- fine sand: diameter up to 0.2 cm;

- medium sand: from 0.2 to 0.25 cm;

- coarse sand: from 0.25 to 0.5 cm.

Fields of application

From the above, an attentive reader, as well as a more experienced user in this matter, should already understand that for different types of construction work it is best to choose a more suitable type and type of sand, since there are basically no universal solutions in this matter. Let's look at the three most classic cases, and determine which sand is best for each of them.

From the above, an attentive reader, as well as a more experienced user in this matter, should already understand that for different types of construction work it is best to choose a more suitable type and type of sand, since there are basically no universal solutions in this matter. Let's look at the three most classic cases, and determine which sand is best for each of them.

Sand for construction

If you intend to purchase the majority of building materials from a reliable and trusted company, however, do not forget to check it, because you cannot build business relationships on one trust. And since the construction process is very important, then the sand for him must be appropriate.

First of all, it should be dry and cleaned thoroughly, and its density should reach about 1.3 tons per cubic meter. If this indicator significantly exceeds this mark, this can tell us that either there is a large amount of extraneous impurities, or it is too wet.

Sand for masonry and decorating

Since for the solution used in masonry If you need high-quality sand that can quickly remove moisture, you often use a river version in a batch. As we recall, this type of sand costs a little more than career sand, and therefore the overall cost may increase, but its use makes the mixture more durable, and at the same time flexible.

Solution for finishing work, and more specifically plastering, best done on the basis of quarry sand, which will provide good adhesion to the working surface due to the sharp edges of small grains of sand. The presence of clay in the impurities, which acts as a well-binding element, also has a positive effect.

Foundation sand

Since there is not much to talk about the importance of having a foundation and its stress resistance to various conditions, it is worth noting that quarry sand with medium-sized grains is best suited for it. Among all the possible options, it has a combination of all the necessary indicators and is very affordable in terms of cost.

Since there is not much to talk about the importance of having a foundation and its stress resistance to various conditions, it is worth noting that quarry sand with medium-sized grains is best suited for it. Among all the possible options, it has a combination of all the necessary indicators and is very affordable in terms of cost.

Quality definition

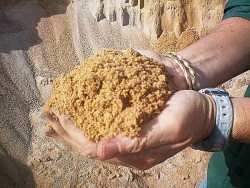

Many experts recommend on their own, at what it is best to determine the quality of sand before buying or already upon delivery. And according to their statements, this can be done in two ways: visually and tactfully, in simple terms - to look and touch.

Many experts recommend on their own, at what it is best to determine the quality of sand before buying or already upon delivery. And according to their statements, this can be done in two ways: visually and tactfully, in simple terms - to look and touch.

Visual way determining the quality of sand includes the presence of a compact sieve through which it will be possible to sift this sand. Based on the remaining possible impurities and the size of the fractions, provided that the above information is already obtained, you can easily determine both the type and type of sand.

For example, if its particles are as large as possible and practically free of extraneous impurities, then it will be quartz sand, respectively, and if, say, clay remains in the sieve, then this is the most common career option.

Tactile way even simpler than the previous one and, as you might guess, all you need to do is take a little sand in your palm and squeeze it in a fist. Naturally, if after this procedure you managed to create a lump of sand from this sand, then this is still the same quarry sand and you should not believe the words that it is simply wet. If it were sand of any other kind, even in a wet state it would have remained very crumbly.

There is also third way determine the quality of sand and for this you will need a transparent container, the role of which is best suited ordinary plastic bottle. Next, only a few simple steps are worth it:

- pour clean water into the bottle;

- pour a small amount of sand there;

- shake the contents and leave for about a day.

After 24 hours, you will be able to understand how high-quality sand is, just by looking at this very bottle. The thing is that if the sand is not properly processed, then the water in the bottle becomes cloudy. While high-quality cleaned sand will lie at the bottom, practically without coloring the water. Yes, this method also has a place to be, but on a large scale it is simply not profitable due to the amount of time spent on checking.

The supplier

Turning to the direct order, buying sand, it is important to choose a high-quality and reliable supplier who will be able to offer the cleanest, necessary, type of sand at an adequate and appropriate cost.

Turning to the direct order, buying sand, it is important to choose a high-quality and reliable supplier who will be able to offer the cleanest, necessary, type of sand at an adequate and appropriate cost.

Regarding pricesFirst of all, it is better to familiarize yourself with the price list in order to understand what you have to deal with. Of course, it’s quite natural that a quality filtered sand can cost more than ordinary, non-sifted sand.

Also, any supplier must provide accompanying documentation, reporting on the characteristics of this type of building material, during registration and signing of the contract. This information should be as accessible as possible even for a person who may not be too familiar with this field of activity. First of all, it will be a sign that the supplier is as open and honest as possible.

The presence in the company of a manager who promptly advises on all possible emerging issues regarding sand also indicates the seriousness and reputation of the company. You should always be served by an intelligent specialist who, in case of confusion, will help clarify a particular situation for you.

And since we started talking about specialists, each serious supplier company should provide the most comfortable sand delivery services, having its own freight transport, as well as personnel capable of serving it.