Welded Mesh Fence: 8 Tips For Choosing

Fences made of welded wire mesh and welded panels were subdued by their low cost, ease of installation and durability. They are actively used to protect private areas, warehouses, sports fields, farmland and industrial enterprises, construction sites and kindergartens. Despite some simplicity and even primitiveness of the design of such a fence, a lot of its varieties are distinguished, which it does not hurt to deal with before choosing a fence from a welded mesh.

Pros and cons of mesh fence

A fence of this kind is used, for the most part, to indicate the boundaries of the territory, but if you correctly design the fence, then it can be made part of the interesting landscape design

The advantages of welded wire mesh fences include:

- affordable cost;

- simplicity and high speed of installation;

- the fence will not become an obstacle to sunlight and air flow, which will positively affect the plants grown;

- the grid will not hide from you what is happening outside the site, so you can enjoy the picturesque scenery;

- durability from 10 to 50-60 years, it all depends on the type of coating. The galvanized grid will not need constant care and will last a very long time;

- light weight simplifies transportation and installation;

- the grid withstands strong gusts of wind, is sufficiently durable, so that it can withstand the weight of a person or a climbing plant;

- safety for children due to the lack of sharp corners and harmful fumes.

Minuses:

- the fact that everything is clearly visible through the grid is perceived by many as a drawback. A compromise solution is to put the grid where the trees grow densely so that the site is not visible to outsiders;

- maximum height of the fence - 3.5 m;

- the mesh fence cannot be called unaesthetic, but in appearance it is inferior to many analogues;

- the design is unlikely to become a reliable barrier to intruders.

Application area

Application area

Fence from welded wire mesh can be of absolutely any length, so they will be able to protect any territory. Similar designs are used for fences of private houses, industrial areas, construction sites, kindergartens and schools, sports fields, etc. - Examples can be given a lot.

In addition, the welded mesh is actively used and in agriculture when arranging pens, cages, pastures and land.

In construction Welded wire mesh is used in the installation of pavement, paving slabs and building foundations to strengthen the structure and prevent mechanical damage.

Wire Diameter and Cell Shape

Welded wire mesh is made of steel wire. The latter is first leveled, and then cut into segments of the desired length, after which bends are formed by a bending machine, which eventually become stiffeners. The final stage is spot welding, after which it is possible to apply a protective zinc layer, and possibly a polymer one.

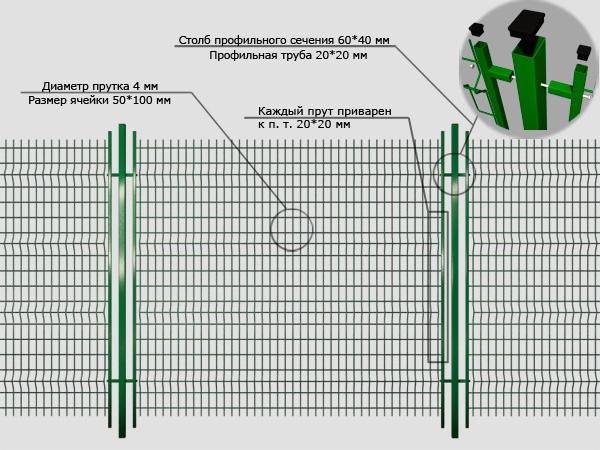

wire diameter in welded wire mesh does not exceed 4 mm, and wire products with a diameter of 5-6 mm are usually called welded panels. Naturally, the thicker the wire, the stronger the structure comes out.

Wire can be molded cells of various shapesbut usually use the following options:

- square and rectangle;

- rhombus;

- trapezoid (usually made to order).

Welded wire mesh (diameter up to 4 mm) is transported in rolls. At the installation site, the roll is easily deployed, and the grid itself quickly comes into shape. Welded profiles are made of thicker and stronger wire, so that it cannot be bent into a roll - such products are transported by cards, i.e. finished sheets that remain to be fixed on a support.

Type of mesh coverage

According to on the availability and type of coating welded wire fences are:

- without protective coating - The cheapest option that requires the most care. If you do not regularly update the paintwork, the structure will quickly rust and become worthless;

- galvanized wire mesh not afraid of moisture due to the presence of a protective zinc coating. It can be applied to a wire, from which they then make a mesh, but more often galvanize ready-made welded construction. Zinc is applied by galvanic or hot method. The second option is somewhat more reliable, but also much more expensive;

- PVC coating receive some galvanized nets, due to which they acquire maximum durability. It turns out that zinc protects steel from corrosion, and polymer spraying protects the zinc coating. The durability of such products is up to 60 years or more. The polymer coating is usually made green, but other options can also be found, and some manufacturers custom-painted the mesh in any shade of the RAL palette.

The structure of the welded mesh for the fence

The type of construction design affects both the strength and the appearance of the fence:

- grid 2D - flat, has square or rectangular cells. She does not have any protrusions, bends and other relief elements, because it is cheaper, although it is inferior in strength to the 3D version;

- mesh 3D characterized by the presence of characteristic bends, which can be located both at the top of the structure, and in any other place. Such elements play the role of stiffeners, reinforcing the fence and making its appearance more interesting.

Mesh fence design

The design is most affected by the diameter of the wire used to create the fence. Mesh fences can be divided into two types:

- sectional fence, often referred to as European. Such a fence is erected from welded panels, which are delivered by cards. Manufacturers supply such products with all necessary fasteners, thanks to which the fence is assembled very quickly, and special skills are not required. Strength and attractive appearance allowed the structures to be actively used in parks, for fencing office buildings, etc .;

- tension fence obtained from a less durable mesh, exactly the one that is transported in rolls. It costs less, but in terms of installation is more complicated. It is necessary to build metal, wooden or concrete poles. Concrete supports are considered the most reliable and durable.

What is important to consider when choosing?

To make the fence strong and durable, when choosing, pay attention to the following nuances:

- strength depends not only on the thickness of the wire, but also on the size of the cell. A thicker rod and a smaller cell allow you to get a more solid structure;

- around the perimeter, the mesh size and the thickness of the rod should be the same. In addition, the rods themselves must be smooth, without any defects;

- during inspection, pay special attention to the integrity of the protective layer, because the durability of the entire structure depends on it;

- welding places when unrolling the roll should not crack;

- all fasteners and other accessories must be well-packed;

- grid size is selected depending on the goals. The length of one roll can reach 30-50 m, and the width varies from 0.5 to 2 m or more, and the height of the fence depends on the width;

- certificate of conformity.

Mounting Features

The easiest way is to install a welded fence using metal poles. The procedure will be as follows:

- marking up the territory.Pegs are driven in at locations of future angles. Twine is pulled between them, and then pegs are driven in at equal distances from each other in the places of future supports;

- dig a hole under each support. Depth depends on the level of soil freezing, but usually stops 1/4 of the height of the support. If the soil freezes deeper, you will have to deepen the pit;

- a pillar is inserted into the prepared hole, it is set clearly vertically and poured in advance prepared concrete. It is better to install spacers so that after the solution has solidified, the column remains vertical. Particular attention is paid to the pillars on the corner and those to which the gate will be attached;

- when the concrete finally hardens, you can proceed to the installation of the mesh. As fasteners use special clips or staples with a bolt and nut;

- most manufacturers attach detailed installation instructions, so there should be no question.

The process is described in more detail in the video.

Application area

Application area