Warm floor under the laminate: how to choose and install with your own hands

Underfloor heating systems that can be laid under the laminate

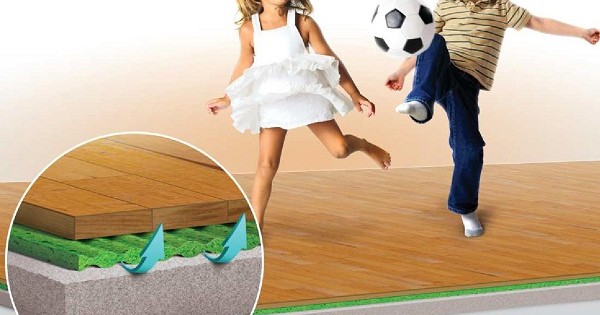

The advantages of laminate over others floor coverings lots of. This is its affordability unlike parquet boardwhich requires a significant budget. Though laminate flooring is not as durable as parquetYet it has a good life. Ease of laying it will allow you to easily replace some part of the coating that is deformed and to easily return the original appearance to the laminated floor without spending a lot of money on it, as is the case with parquet floors. For those who decide to install a warm floor system in their home, a final coating of laminated panels will be the best choice.

The advantages of laminate over others floor coverings lots of. This is its affordability unlike parquet boardwhich requires a significant budget. Though laminate flooring is not as durable as parquetYet it has a good life. Ease of laying it will allow you to easily replace some part of the coating that is deformed and to easily return the original appearance to the laminated floor without spending a lot of money on it, as is the case with parquet floors. For those who decide to install a warm floor system in their home, a final coating of laminated panels will be the best choice.

To better understand which system of underfloor heating to choose, let's take a closer look at each option from the existing ones in more detail. The modern construction market today offers three main types of underfloor heating, which have different types of structural solutions, but are equally suitable for laying under a laminated floor.

- Electric underfloor heating (cable floor) - this heating system is based on the principle of converting electric energy into heat through special heating elements that are evenly distributed on the floor surface and heat the room. Installation of cable underfloor heating does not require special expenses and separate additional systems, just “plug it into a power outlet” and adjust the heating intensity depending on the ambient temperature.

- Water floor heating - this type of heating system is based on the principle of heat exchange of a circulating heated liquid (water) through special pipes with a floor covering. Tubes are placed in the same way as in the first case - evenly over the entire floor area, under the floor covering. This is one of the most cost-effective options, since water can be heated by a gas boiler, and not by electricity, which is more expensive. This option is suitable for people who are used to save.

- Infrared Warm Floor - This technology works on the principle of converting electrical energy into infrared radiation, that is, thermal.

The main advantages of underfloor heating systems

- All three types of underfloor heating have common positive characteristics, which are uniform heating of the entire space of the room, thanks to the impressive area of the "radiator", that is, the heating elements themselves.

- The second positive point is compatibility with any design solution, which will be implemented indoors, because such a heating system will not be visible under the laminate floor.

- Another positive feature is lack of "cold zones" and uniform heating with the direction of heat from floor to ceiling.This gives a more efficient heating and with properly implemented insulation of a house or apartment it will be quite economical in terms of costs for electricity or gas.

Which system of underfloor heating is better to choose for laying under the laminate

Let's take a closer look at each type of warm floor and consider in more detail their capabilities and design features. Since each of them has its positive and negative sides. This will help you better understand what type of underfloor heating is best for laying under a laminate floor.

Electric underfloor heating (cable floor)

Electric or cable warm the floor has a construction consisting of two layers.

Electric or cable warm the floor has a construction consisting of two layers.

- Firstof which is a special shielding insulation, which prevents heat from escaping to the base of the floor and retains heat in the room. With the correct and high-quality installation of thermal insulation and the use of expensive building materials, heat savings can be about 10-15% or even more.

- Second layer the heating elements themselves are in the form of a cable, which is evenly distributed over the entire floor area and is attached to a special grid, then a thin screed made of cement or concrete mortar is poured on top.

This is a very easy-to-assemble floor that going in a few hours, thanks to its simple design and ease of connection to power. The thickness of the screed of the heating element itself ranges from 3 to 6 centimeters. Also a feature is a very precise adjustment of the degree of heating up to one degree and minutes. This will allow you to control the consumption of electricity and turn on or off the heating as you wish.

Although adjusting the intensity of heating is a big plus, it still consumes quite a lot of electricity on the electric (cable) floor. The disadvantage is that there is the possibility of overheating the cable of the heating system and as a result, it can burn out. But it all depends on the quality of installation of a warm floor and the use of high-quality building materials. This design is easily combined with laminate flooring and in case of any problems you can easily unmount and fix the damage.

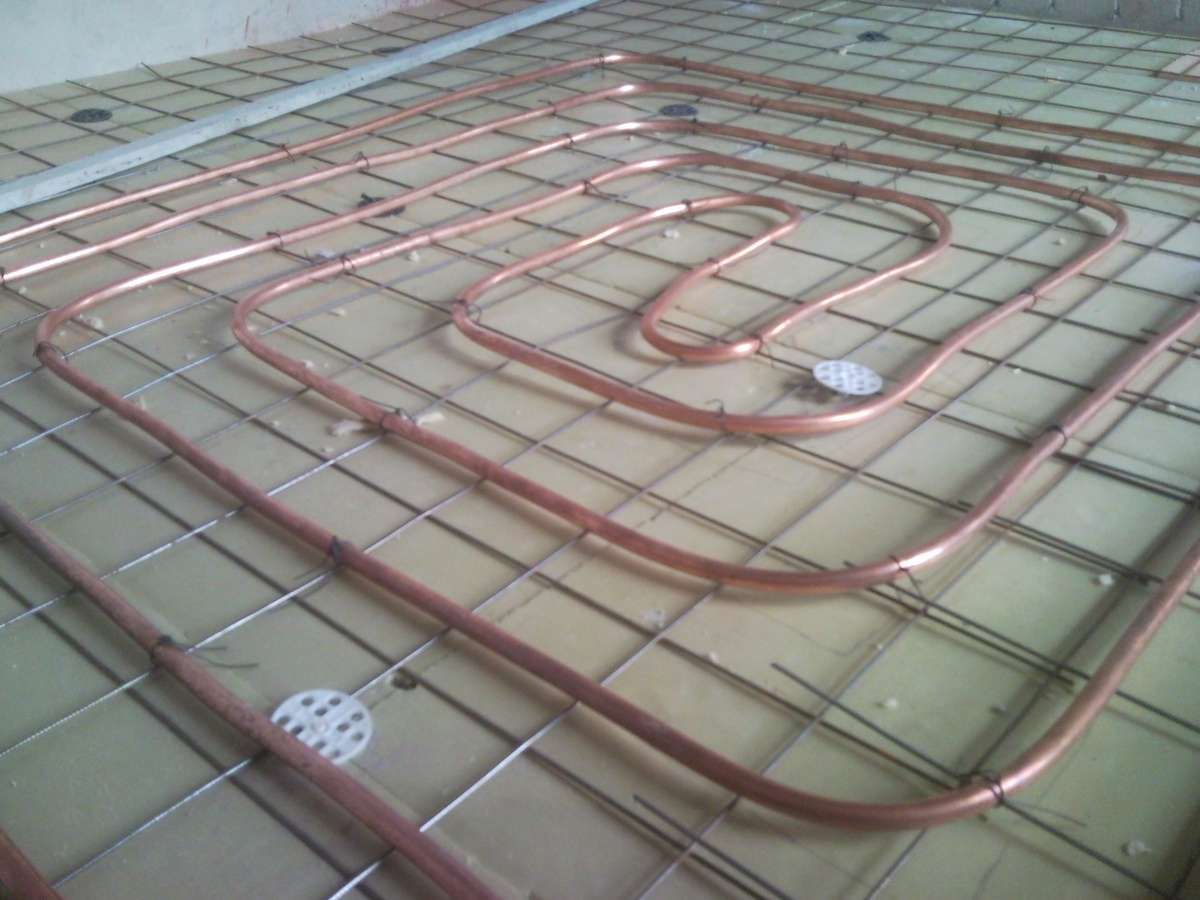

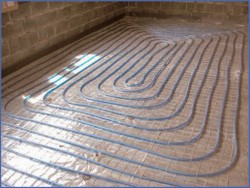

Water floor heating

This type of floor heating unlike the previous version, it has a more complex design, since pipes that hold hot water are used as a heating element. This requires additional costs for waterproofing and an additional pipe system for connecting to equipment that will heat this water. The heating equipment is a gas boiler or electric boiler heating, the installation of which also requires financial costs.

This type of floor heating unlike the previous version, it has a more complex design, since pipes that hold hot water are used as a heating element. This requires additional costs for waterproofing and an additional pipe system for connecting to equipment that will heat this water. The heating equipment is a gas boiler or electric boiler heating, the installation of which also requires financial costs.

The water floor system consists of four layers.

- The first of which is a waterproofing protection, cutting off water tubes heating from the base of the floor. The waterproofing protection acts as a safety barrier in the event of a break in the pipes, which is extremely rare, but can happen.

- The second layer is a heat-insulating layer that creates a screen of heating elements and does not allow heat to go to the base of the floor.

- The next third layer is actually a system of heating pipes or a heating circuit.

- And the last layer is a layer of cement screed or self-leveling mixture.

The advantages of a water floor heating is him electricity independence, unless, of course, the water is not heated by equipment that runs on electricity. Indeed, in the event of a power outage, heating will stop. If the circulation of hot water stops, for some reason, then the water will give off heat for quite a long time.

The downside of this type of underfloor heating is the thickness of the heating element, which can reach 15 centimeters, which is very difficult to create a screed, because it will be difficult to make such a plate, which will require significant financial costs. There is also the risk of a breakthrough of the heating circuit and the formation of an undesirable flood, which can ruin the relationship with the neighbors below if you live in a multi-storey building. Or damage to the decorative coating, in our case, the laminate. therefore laminated manufacturers panels are not advised to use their products as a finish layer in water heating of the floor. But it all depends on the quality of building materials and the professionalism of the masters who will perform the laying of the warm floor.

Infrared underfloor heating

The main feature of this type of underfloor heating is its design, which is a filmconsisting of heating infrared elements. Unlike cable or pipe systems, it is easy to install and does not require special fasteners or other additional building materials, for example, to create a screed. When installing an infrared warm floor, the creation of a screed is not required and the finishing decorative coating can be laid on top, which is very convenient and fast.

The main feature of this type of underfloor heating is its design, which is a filmconsisting of heating infrared elements. Unlike cable or pipe systems, it is easy to install and does not require special fasteners or other additional building materials, for example, to create a screed. When installing an infrared warm floor, the creation of a screed is not required and the finishing decorative coating can be laid on top, which is very convenient and fast.

This floor consists of three layers:

- The first of which is penofol or penoizol screen, represent a layer of foil and foamed polymer, which prevents heat from escaping into the floor and leaves it indoors.

- The second layer is itself film with infrared heating elements that are very easy and quick to mount on the floor.

- Well, the last layer is a finishing coating.

The effectiveness of this floor is very high and has an indicator Efficiency of about 90 percent, since there is no screed and a small thickness of the entire system, which is only 2-3 centimeters, which allows heat to freely pass through the finish of the laminate into the room.

It should be noted that the energy consumption of an infrared warm floor is much lower than that of a cable heater, but the heating film itself is more expensive than a system of heating wires. Another plus is the easy replacement of failed sections of the infrared film, which in the event of a break in any place does not fail along the entire floor surface, as is the case with cable underfloor heating.

Such a warm floor will be easy to match with laminate flooring, since it allows you to lay it directly on the infrared film of the heater. Manufacturers are positioning this floor, as an ideal solution for laying laminate on it. Often the way it is, it all depends on the quality and strength of the infrared film. Indeed, with strong pressure on the laminate floor, the heating elements of the film can be damaged, which may lead to rupture, so this should also be taken into account when choosing a warm floor on the infrared principle.

Some tips for choosing the best underfloor heating system

In principle, each of the three types of underfloor heating, which was described above, can be used under the laminate floor. The main thing is that the quality of materials and the professional skills of the specialists who will install the underfloor heating and laminate are high. In order to avoid unpleasant consequences should not save on building materials and try to use products where new developments are applied, with which manufacturers improve their products.

In principle, each of the three types of underfloor heating, which was described above, can be used under the laminate floor. The main thing is that the quality of materials and the professional skills of the specialists who will install the underfloor heating and laminate are high. In order to avoid unpleasant consequences should not save on building materials and try to use products where new developments are applied, with which manufacturers improve their products.

- The most advanced in this regard is film floor heatingwhich is best suited for laying under the laminate. The main advantages of this type of underfloor heating are its low energy consumption, unlike cable underfloor heating, the simplicity and ease of installation of the entire system does not heat the laminate board above 26 degrees, which can cause the formation of formaldehyde vapor, which is often used by laminate manufacturers, in the manufacture of products. But the more expensive types of laminate flooring have environmental safety, so the last factor should not be given much importance.

- Electric (cable) floor is also good and effectively warms the room, but it is more difficult to install and in some cases can be more expensive than a film heat-insulated floor. However, when creating a screed, the cable system will not be damaged by the load that will come from furniture or heavy equipment, but this can damage the film system. But it all depends on the correct installation and quality of materials, as well as a significant budget will allow you to purchase products from the best manufacturers.

- It is undesirable to install a water floor under a laminate coating, as there is a risk of breakthrough water pipes that are mounted throughout the room. But here the same situation, if everything is done at a high level, there will be no problems. Moreover, a water heated floor is considered the most economically viable, since heating water with gas is much cheaper than using electricity.

Instructions for self-installation of underfloor heating under the laminate (for example, film underfloor heating)

Each type of warm floor requires its own approach to laying it on the surface, but the main thing is to follow the basic rules that must be observed for a more efficient and safe use of this type of heating. As an example, let's look at laying an infrared film underfloor heating, which suits the laminate flooring best. But this is not necessary, because other types of underfloor heating also have their advantages.

Each type of warm floor requires its own approach to laying it on the surface, but the main thing is to follow the basic rules that must be observed for a more efficient and safe use of this type of heating. As an example, let's look at laying an infrared film underfloor heating, which suits the laminate flooring best. But this is not necessary, because other types of underfloor heating also have their advantages.

- First stage - First, the preparation of the floor surface, i.e. alignment and removal of all defects, such as cracks or through holes. Infrared film, like other types of underfloor heating, requires a perfectly flat surface, so this is an important stage of work. The ideal is to use a ready-made self-leveling cement screed.

- Second phase - Next, on the prepared surface that has been leveled, lay the next layer of penofol or penoizol, which is a shielding heat insulator, one side of which is made of a foil coating. This heat-insulating material prevents the loss of heat that can escape to the base of the floor. This stage is carried out after the screed has completely dried, which should have a perfectly flat surface.

- Third stage - installation of a warm floor when laying an infrared heating film. When installing the infrared floor, you must expand the roll and divide it into strips that must correspond to the dimensions that are required for the insulated zone. The film is laid with the copper side down to the insulating layer. The distance between the strips should be at least 10 millimeters, and the indent between the strip and the wall should be 50 millimeters. You should also consider the length of the strip, which has limitations.

If the width of the infrared film strip is 80 centimeters, then the length should not exceed 10 meters.

If it is 50 centimeters, then you can use the 13-meter length of the strip. - Fourth stage - connection of contact clamps, which is easy to do with pliers. Usually the contacts are located at the very skirting boards on the copper side of the infrared heating film. Contacts that have not been used should be isolated with special bitumen mastic.

Next, you should install the temperature sensors, attaching them to the contacts and hide the line behind the baseboard. After all the lines are connected to the contacts together with the temperature sensors, you should connect to the control unit. - Fifth stage - The finishing step, which involves laying a laminate or other flooring. Read more about laying laminate flooring. here.

Which laminate is suitable for a warm floor?

At choosing a laminate for a warm floor, the thermal load that will come from these heating systems should be taken into account.After all, the laminate flooring can be deformed along the joints, which will lead to damage to the floor surface and ruin the aesthetics of the interior. Modern types of laminate are divided into classes that indicate the resistance of the coating and its wear resistance, it also shows its resistance to temperature changes and indicates the service life.

At choosing a laminate for a warm floor, the thermal load that will come from these heating systems should be taken into account.After all, the laminate flooring can be deformed along the joints, which will lead to damage to the floor surface and ruin the aesthetics of the interior. Modern types of laminate are divided into classes that indicate the resistance of the coating and its wear resistance, it also shows its resistance to temperature changes and indicates the service life.

- Class 31 laminate It has medium strength and will last about 10 years. It can be used in offices with few visitors and at home where it is best suited.

- Next in seniority class is 32. It can be used in offices with medium traffic, as well as in hospitals and schools. The service life is about 15 years.

- Next class - 33, which has excellent strength and wear resistance, and also well resists the temperatures that a warm floor emits. It can be used in places with high traffic. Some manufacturers give a lifetime warranty on their laminate class 33.

This shows that laminate flooring of the highest class is better for a warm floorto avoid unpleasant consequences.