Tips for choosing glue for gas blocks and foam blocks

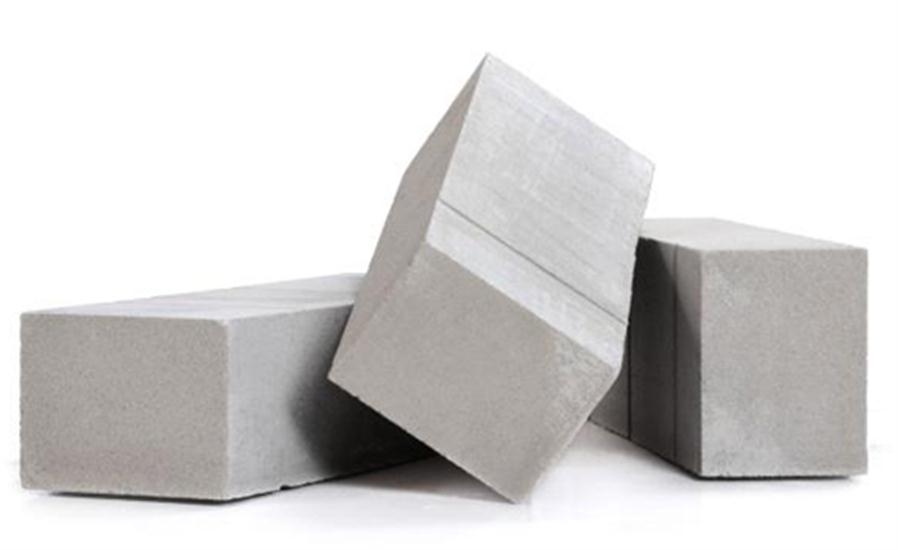

Over the past few years, the popularity of “porous” blocks made of cellular concrete, namely gas and foam blocks, currently actively used in the construction of buildings and residential private houses, has grown very much due to their greater accessibility and practicality, if you, of course, know all the nuances and subtleties when working with them.

And choosing them as the basis for the building material, the next relevant and no less important question for you may be how exactly the masonry will be made. The use of cement mortars in the construction of structures from this type of block is not only obsolete, but simply will be impractical, since the cost of cement will be quite high, given the considerable consumption of the mixture. This is mainly due to the fact that the blocks, having a “porous” structure, suck out most of the moisture from it during the solidification of the solution, making the brickwork less durable.

That is why today, when building using gas or foam blocks, most craftsmen prefer special glue. Naturally, it can be of different types, grades and structures, and it is better to use a certain glue for this or that type of block.

So, if you decide to start building a house and don’t know which glue is better to choose, then pay attention to this article, which presents several tips to help you make a choice.

Mixture composition

Naturally, the adhesive for laying cellular blocks comes in the form of a dry mixture from which it is subsequently made. Such a mixture is always based on Portland cement, which is essentially very fine quartz sand, due to which the strength of the already hardened composition is achieved.

In addition to it, there are also various modifiers that retain moisture, allowing the glue to harden properly, and also prevent the appearance of cracks, which is also completely undesirable. The plasticity of the mass, which allows the composition to fill all the cavities, is increased by various polymer additives, which in turn increases the adhesion between the block and the solution, ensuring the strength of the structure.

Types of glue

The construction process is almost a year-round business and you never know what weather it will be produced in, whether it is hot summers or snowy winters. Of course, in most cases, many builders and construction companies try to plan their work, but if you do not want it to stand still in a certain season, then manufacturers of building materials and in particular adhesive compositions provided the market with two types: summer and winter.

The construction process is almost a year-round business and you never know what weather it will be produced in, whether it is hot summers or snowy winters. Of course, in most cases, many builders and construction companies try to plan their work, but if you do not want it to stand still in a certain season, then manufacturers of building materials and in particular adhesive compositions provided the market with two types: summer and winter.

Summer team:

The characteristics of this mixture is white cement, and it sets in two hours after adding water, so you need to carefully monitor this. Naturally, this glue is used during construction in the warm season, and the working temperature is considered to be from 5 to 30 degrees Celsius.

Winter composition:

Here it can be judged from the name that this mixture is used to work in colder weather, with temperatures from +5 to -10 degrees Celsius on average. In fact, this mixture has the same composition, but in addition to the main components, it also includes antifreeze.It is necessary to dilute the mixture with water, which according to the instructions must be heated to 60 degrees, and such a mixture solidifies in just 30-40 minutes, so it is best to knead the glue in small portions and work quickly.

The proportions of the solution

Basically, professional builders always know what proportions of the components are needed for a certain amount of the mixture, but if you are just starting to become interested in this topic, you can always find the “recipe” for preparing the solution on the bag with the composition. The rules for preparing the mixture will also be located there.

Basically, professional builders always know what proportions of the components are needed for a certain amount of the mixture, but if you are just starting to become interested in this topic, you can always find the “recipe” for preparing the solution on the bag with the composition. The rules for preparing the mixture will also be located there.

But if for some reason they were not there, it is worth noting that they are quite simple and will be available to absolutely everyone:

- pour the contents of the bag (approximately 25 kg) into a clean container;

- pour in about seven to eight liters of water;

- with help mixer drills mix the mixture at a low rotation speed, bringing the solution to a homogeneous state;

- after five minutes of "ripening" of the solution, it can be used.

This is what the standard cooking instruction looks like, and checking the plasticity of the mixture will be quite simple, you just need to put it with a spatula on the surface of the block and see if it spreads. When thickening, the adhesive can always be stirred with a mixer, but still you should not keep the mixture unworked after more than 2 hours.

It will also be important to note, as already mentioned above, that the technology for preparing glue from the winter composition is very slightly different from the main one as follows:

- water should be hot (at least 60 degrees Celsius);

- the temperature of the finished working mixture should not fall below the mark of +10 degrees;

- the duration of the "life" of such a solution at sub-zero temperatures of no more than half an hour;

- Never apply glue to blocks covered with frost, hoarfrost or snow.

Masonry process

First of all, it is worth noting that when working with foam blocks, the first row is always placed on the cement mortar, in order to avoid various (probably possible) irregularities of the foundation, and from the second row glue is used.

First of all, it is worth noting that when working with foam blocks, the first row is always placed on the cement mortar, in order to avoid various (probably possible) irregularities of the foundation, and from the second row glue is used.

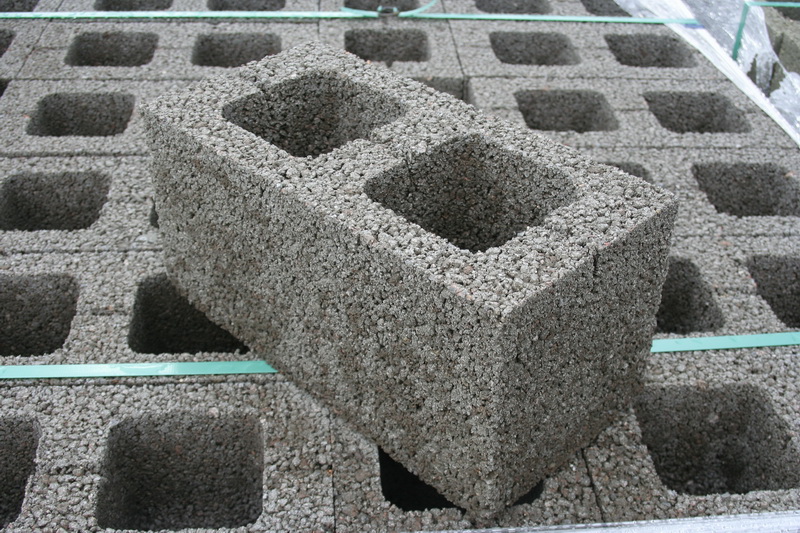

During the laying process, if you are working with ordinary, standard blocks, then glue must be applied not only to horizontal faces, but also to vertical ones. In the case of using blocks with a groove-comb connection, the application of adhesive solution on the vertical ends is optional, if not necessary.

Naturally, the blocks themselves immediately before installation are also best prepared by cleaning them from dust and possible fine dirt, so that the glue is applied to an absolutely clean surface.

Advantages of Using Glue

The use of glue for laying blocks of cellular concrete has a number of positive features, which in turn affect many more or less important indicators, both at the construction stage and in the final analysis.

Among the main advantages are the following:

- the possibility of achieving a minimum thickness of the seams, which in turn virtually eliminates the formation of “cold bridges”, which does not allow frost to get into the house;

- taking into account the same small thickness of the joints, the consumption of the adhesive mixture is much less than that of cement-sand;

- time savings achieved by reduced laboriousness of production and preparation of the solution, which is required in small quantities;

- there is no need for any bulky mixer, everything is done with your own hands using a construction mixer or a drill with a special nozzle;

- also rise heat- and soundproof properties of the walls of the foam block;

- excellent moisture-resistant qualities of the mixture exclude moisture absorption, and, consequently, the formation of fungus mold etc.;

- production becomes much easier, but thanks flat walls cost is also reduced finishing work;

- and, of course, all the components that make up the mixture do absolutely no harm to the human body;

disadvantages

As for the shortcomings, in terms of the direct use of the adhesive mixture they are not.But the cost of these compounds is still relatively high, so at this stage they are mainly used for small buildings.

As for the shortcomings, in terms of the direct use of the adhesive mixture they are not.But the cost of these compounds is still relatively high, so at this stage they are mainly used for small buildings.

However, despite the fact that cement mortar it can be much cheaper, with the right geometry and accurate calculations, you will probably be able to save a lot of money, since with the above advantages and great plasticity of the mixture, the adhesive on the masonry can go up to six times less than cement mortar. And here you do not need to be a mathematician to calculate the difference in costs, so this drawback is also very ambiguous.

The best manufacturers of adhesives

So, you decided to use glue for laying your future home or other building and it is time to choose the composition on which you will assign one of the most important missions, namely the strength and integrity of the structure.

So, you decided to use glue for laying your future home or other building and it is time to choose the composition on which you will assign one of the most important missions, namely the strength and integrity of the structure.

Today, the market for building materials is filled with various companies and brands, and the category of mixtures is not an exception at all, providing a fairly wide selection. So for a more optimal solution, it is worth considering the three best and most popular options, from world leaders and simply proven brands.

Ceresit

One of the most popular brands of building materials, mixtures and other things is the brand Ceresit and she deservedly occupies a high position, thanks to numerous recommendations and her exceptional quality.

One of the most popular brands of building materials, mixtures and other things is the brand Ceresit and she deservedly occupies a high position, thanks to numerous recommendations and her exceptional quality.

Made on the basis of cement with mineral fillers and an organic modifier, Ceresit adhesive mixture is perfect for thin-layer laying of exterior and interior walls from gas or foam blocks.

This adhesive is produced in bags weighing 25 kg.

Knauf

Also quite a popular solution among many construction companies and professional builders themselves are compositions from Knaufwhich, thanks to their gypsum base, provide high and lasting grip quality.

Also quite a popular solution among many construction companies and professional builders themselves are compositions from Knaufwhich, thanks to their gypsum base, provide high and lasting grip quality.

Eco-friendly adhesive Knauf perlfix It does not have any adverse effects on a person, and its plasticity allows you to quickly align the blocks.

This adhesive composition is produced in bags weighing 30 kg.

IVSIL Block

Excellent dry mixes suitable for foam and gas blocks can also provide IVSIL Block. This glue is well suited for both grooved and conventional blocks, and the composition of this glue mixture contains various imported polymer additives that significantly increase adhesion (adhesion between the block and the glue).

Excellent dry mixes suitable for foam and gas blocks can also provide IVSIL Block. This glue is well suited for both grooved and conventional blocks, and the composition of this glue mixture contains various imported polymer additives that significantly increase adhesion (adhesion between the block and the glue).

The big advantage of this mixture is the ability to adjust the position of the blocks for up to 25 minutes, when in many other cases this time is only 3 minutes.

This adhesive is produced in bags weighing 25 kg.