Selection and installation of the furnace in the bath

One of the most important factors in building a classic Russian bath is the selection and installation of the furnace. The right choice is important not only for the observance of the traditional style of the Russian bath, but also in terms of technical characteristics, such as fire safety, the heating rate of the bath, the softness and saturation of the steam, the presence of convection, etc. As you know, traditionally used in a Russian bath brick kilns with a specific design designed specifically for the bath. Considering that not everyone has the option of making an oven to order, today the market is full of factory models for every taste. The only difficulty: choose the optimal model that will meet your needs and all the parameters of the steam room.

Choosing a stove for a bath

Classification of furnaces: by type of fuel

So there is three different types of heaters and one combined:

- wood;

- gas;

- electric;

- gas-wood, respectively.

Each of them can be adapted to your type of steam room, despite the fact that only a wood-burning stove is recognized as true connoisseurs. Although, this is not surprising, since the wood stove is superior to all others in the comfort of the procedures themselves. In such a bath it is quite easy to breathe, the atmosphere is natural, and the air is optimally humid. The only drawback is the complexity of maintenance.

The furnace on a thermoelectric heater significantly overdries the air, compared to a wooden one. In addition, the heater consumes a lot of electricity, so if you take a steam bath for a long time, this can be a very expensive pleasure. Gas stoves are almost not inferior in characteristics to wooden ones, but here it is difficult to install gas equipment, and in the presence of gas mains in general.

Differences in Functionality

Among the varieties bath stove by functionality are found:

- furnaces with integrated steam generators;

- with water tanks;

- with a furnace tunnel for tossing firewood directly from the steam room;

- with convection.

Steam generators are usually installed only in wood or electric heaters. The latter, among other things, have built-in electronics with the ability to program the furnace and remote control modes.

The power of the furnace and the order of its selection

It is very important to make accurate calculations of your steam room parameters. The correctness of the operation of the heating system will depend on this: the main condition that must be met is the power range of the bathhouse. This range should correspond to the nominal mode, otherwise the system will cause a lot of problems, either constantly overheating (in the case of working at the maximum range), or not catching up with the temperature to the desired one in a given period of time. But this is easy to avoid if you know the design characteristics of the bath. Fortunately, manufacturers indicate in the parameters of the furnaces the volume of the steam room for which it is designed (usually in the technical specifications).

When calculating the volume of the steam room, be sure to consider the heat loss from glass doors and windowstherefore, for each such element add 1 cubic meter to the total volume, if you have no time to make more accurate calculations or not.

- Will be wrong choice of heater with power reserve counting on quick heating of the bath and the same quick drying after the procedures. Under these conditions, the steam room will operate at its lower power range and you will not have the opportunity to adjust it. However, the stove will quickly heat the air, but this time is not enough for the stones, so it will not work to get additional steam by pouring water on hot stones - it will be too saturated and heavy.

- On the acquisition of a low-power furnace You will not save either. Working in extreme mode, such a heater will never be able to provide a heating rate unlike optimal (therefore, heating time will increase - and with it costs), and due to constant overload it will simply fail soon.

From the above it follows that before purchasing a stove you must know the heated volume of the bath, taking into account all the nuances and the capacity required by the furnace itself.

The principle of calculating the required power of the stove

As already mentioned earlier, it is not enough to calculate the total volume of the bath room, because there are a number of nuances that need to be taken into account. If you are not impressed by the approximate calculation, then you can follow a few simple steps:

- When you have the total volume of the bath in your hands, it is also necessary to separately calculate the total volume of all non-insulated surfaces (this is not only glass, but also bare brickwork, tiling, etc.). To do this, the surface area of each surface is considered, then multiplied by 1.2 and added to the total cubature.

- Some experts advise that if there are glass doors or windows for more accurate calculations, add not 1 cubic meter, but 1.5 cubic meters;

- In addition, it is necessary to multiply the entire calculated value by 1.5 if the bath consists of logs without thermal insulation.

Having the final size of the room, you should choose a stove with a range in which it fits. Moreover, the value of the volume provided should not be at the boundary points (for example, for a volume of 17 cubic meters, you need to take a furnace with a capacity corresponding to 10-22 cubic meters, but not 17-25 cubic meters).

Also it is important to strictly follow the manufacturer's recommendations when operating the heater. This also applies to acceptable operating modes and the number of stones loaded.

But sometimes it happens that the thermal power is not indicated by the manufacturer in the data sheet. Nevertheless, it is necessary to know this value. As you know, the volume of the furnace is proportional to power. That is, taking as a basis the proportion where the power of the stove with a volume (V) of 30 liters is 15-17 kW, according to the formula where the power of the stove = 0.5xV, you can calculate the power of the stove, knowing its geometric parameters.

Features of a gas furnace

For owners of a gasified bath, preferring convenience over tradition, this stove fits perfectly into the design of the steam room. The comfort of this heating option is several points:

- there is no need to constantly monitor the intensity of combustion;

- no need to harvest firewood and constantly throw them into the furnace during bath procedures;

- there is no need for a stable supply of electricity and related devices (voltage stabilizer, new wiring, high-quality machine, etc.)

- in operation has lower costs than a furnace with a heating element;

- it is possible to take a gas model that combines operating modes both on gas cylinders and on wood.

One more plus of the gas furnace: simplicity in leaving. With gas burner chimney It will be minimally contaminated, unlike wooden, where burning logs smoke walls.

In addition, the gas furnace is easy to operate.After all, it does not leave solid combustion products after bath procedures and does not require tossing firewood into the furnace.

The difficulty of installing a gas furnace

The design of gas equipment provides such a furnace with low weight, but due to fire safety considerations, gas should be handled very carefully and carefully. Moreover, It is not recommended to mount a gas furnace on your own - it is better to entrust it to an experienced specialist, since any slightest mistake in installation can cause an emergency and life-threatening situation. In addition, during installation, it is necessary to take into account all the manufacturer's recommendations regarding the distances when installing nearby wooden coatings, etc.

Wooden or electric: what to prefer?

Climate creation quality

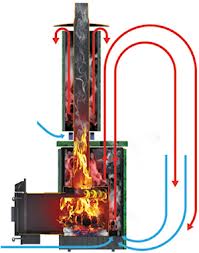

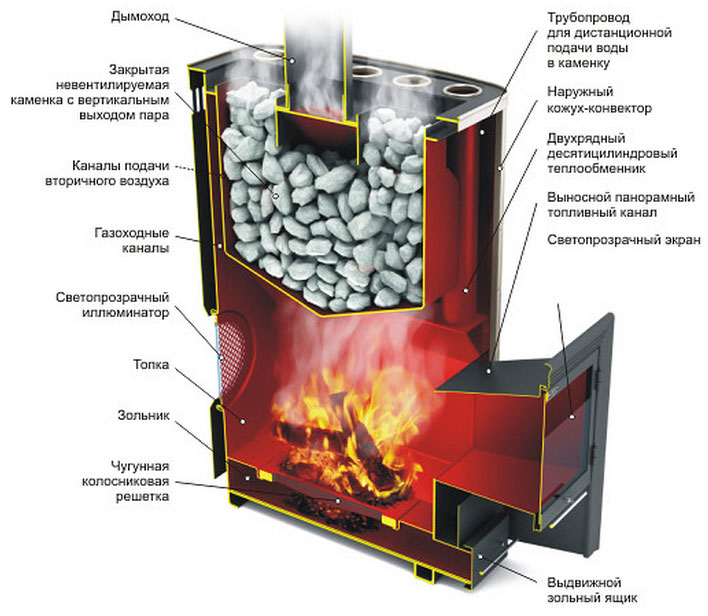

The device of a wood-burning stove

If we compare the electric and wooden stove-heaters in terms of performance, then under the condition of the same external influences, these heaters produce almost equal power heating in a given period of time. But as mentioned earlier, in terms of steam quality, the wood stove is significantly ahead of the rest.

The device of an electric bath stove

The stove must have a convection system;

- So that the heat does not escape too quickly into the environment, the furnace must be thermally insulated, that is, not have large surfaces that emit heat above 150 degrees.

- It is definitely worth constructing a furnace tunnel and there are several reasons for this. These include: the need for a large amount of air to ensure combustion, the possibility of heating from another room (to avoid dirt in the bath, etc.), for proper circulation of air flow, and the latter - the furnace tunnel makes it possible to design a stove in the form of a fireplace.

In general, we can say that in terms of creating a microclimate, a wood-burning stove is much better and cheaper, as it will not require any additional devices to maintain the necessary humidity and steam saturation.

Performance characteristics

In terms of ease of use, a modern anti-wood sauna stove is like a Porshe 911 vs Lada Kalina.

- With an electric furnace, the need for continuous firewood and maintaining a place for them is eliminated;

- During installation, half the labor costs will be required, since the electric furnace does not require a chimney;

- There are thousands of models with remote control that will make the day off in the bathhouse a truly relaxing vacation.

Economic aspect

It is rather difficult to judge here on the one hand, because everything depends on needs, on the method of execution of the furnace itself, on the method of operation, and so on. But judging by the standard situation, then in terms of high cost, in the first place there will still be an electric furnace, in the second - a gas stove and the last - wood.

- When choosing a gas-fired oven high economic costs can be incurred only if you need to obtain a permit for gas equipment or to stretch the pipe from the highway. Otherwise, this is a matter of choice.

- When choosing an electric furnace most of the money will have to be spent on additional devices that create a natural microclimate and, if desired, on electronics to program modes.

- The wood stove in the classic version, it requires almost nothing except the design and construction of the furnace tunnel. Here, the expense will depend entirely on your taste and additional wishes. When equipping a furnace tunnel with a fireplace window, such a furnace can cost no less than an electric one.

Having summed up some results, we can say that according to the selection criteria it is possible to divide the furnace into the following groups:

- if you are not a big fan of a traditional Russian stove, then for you any stove will be almost the same;

- if convenience is very important to you, then an electric oven will be the best solution;

- from the point of view of economy, it is better for lovers of an excellent microclimate in a steam room to choose wood, although its maintenance is very laborious;

- the golden mean in convenience and price is a gas stove.

Basic rules for installing a sauna stove

Installation is a very important stage in creating the perfect bath. And for it to succeed, you must follow a few important rules:

- In brick and metal stoves, in terms of installation, there is a big difference: when a brick is needed, a prepared foundation, metal can be installed directly on the floor.

- At the stage of construction work, you need to think about the chimney in advance: it should have a minimum number of bends. This will provide a high level of efficiency to your heater at the exit.

- Also, in order to save energy inside the system, the chimney near the wood stove should be insulated with a heater to avoid condensation.

- Under the metal stoves, it is necessary to lay thermal insulation material. This will prevent the loss of heat, especially if the bath floor is made of wood.

- If there is an open flame in your stove, it is better to lay a refractory material under it to prevent accidental fire, since coals that have fallen on the wooden floor can become a source of fire.

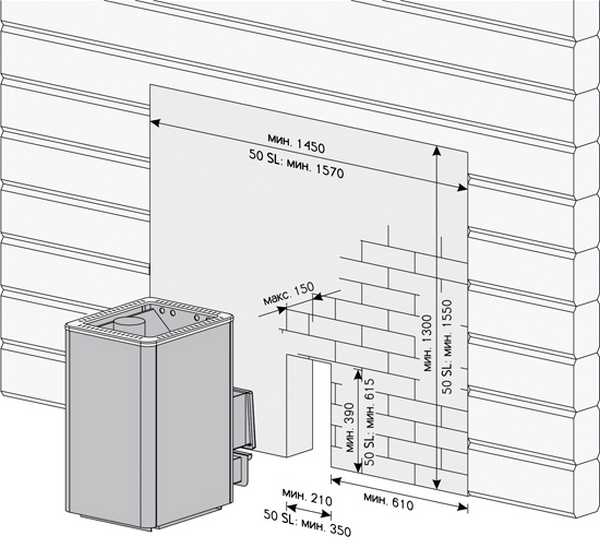

- Also, the kindling zone can be protected with a special insulation shield. The surface of the heater can heat up to 400 degrees during the maximum heating mode. Naturally, intense heat is released from such temperatures, which is reflected from nearby surfaces and materials with a flash point close to the tree, like the tree itself, can easily char or even catch fire. Therefore, shielding a furnace is the right solution. Insulation boards can be purchased at any bathhouse store.

- For the same reason, the stove should be installed in the bathhouse in accordance with the manufacturer’s clear instructions: when buying a stove, make sure that there is an installation instruction with it that lists the distances from the nearest surfaces.

- If you have built a combustion channel, then for the sake of preserving heat, it should also be insulated with thermal insulation material.

- A prerequisite for installing an electric furnace for a bath is its grounding. The best option would be to use a separate circuit for grounding the heater and the machine, which will be configured to emergency power off for any deviations in the network.

Before you start using your bath, you should thoroughly check everything, since self-installation of the furnace and other elements of the steam room requires increased attention. If after completion of work something during operation of the bath is suspicious, it is better to consult with the master.

Wood-burning stove: basic installation steps

Wood burning stove with grate

From the correct installation of the wood-burning stove, its effectiveness and your safety depend. After all, it is much more comfortable to be in the bath when you do not need to constantly worry about the possibility of fire or damage to expensive wooden coatings.

Factory wood-burning stoves: how to install?

There are two types of such furnaces:

- with standard firebox;

- with a separate combustion channel.

As previously stated, the flue channel is very important in maintaining a healthy microclimate in the bath, since with intensive burning of firewood, the air combustion rate is so high that without an additional source, the air in the steam room will not have time to replenish again. In the presence of a combustion channel, it is quite possible to realize additional convection. The convenience of a conventional firebox consists only in the ability to throw firewood directly from the steam room, but this has a number of disadvantages that have been described previously.

The purchase of a factory heater has a big plus: any model can be "customized" to the parameters of your bathhouse by setting the modes, or simply choose the one that is suitable for the characteristics if you are not constrained by the means.

Homemade stoves: how to install?

Here, of course, the situation is more complicated, but if you adhere to two basic rules, installing a home-made heater will not cause any special difficulties.

- Use a thermistor screen. There are two types of panels: steel (cast iron) and brick. They must be installed with a gap of 1-5 cm between the walls of the furnace and the screen. It is not necessary to create a fence around the heater over the entire area, it is enough to protect the side that is too close to the flammable surface. To do this, the front and side screens are sold separately, that is, you can purchase any as needed. Such a shield will reduce the temperature radiated by the furnace from 300 to 90 degrees Celsius. Fortunately, installing them is now quite simple - in modern screens there are special legs for attaching to the floor. In addition to safety, a thermoresistive shield will increase the compactness of your furnace, which can play a significant role in the design of the bathhouse itself and reduce the cost of additional space.

- Any floor in front of the furnace, except for concrete (it can be left as such), must be covered with a protective sheet of metal with thermal insulation. This will prevent it from spoiling in case of accidental ingress of fuel during a tossing.

Brick kiln: basic installation steps

Brick heater

Usually, the first mistake in installing a brick heater is the decision to do it yourself, having an insufficient amount of knowledge and experience. The desire to save on the services of a professional usually leads to fatal errors in the design of the furnace.

If, nevertheless, the desire to make a brick heater with your own hands won, then you will need detailed drawings of both the stove itself and the chimney. You will also need high-quality materials: refractory brick, a special binder material that does not crumble under the influence of critical temperatures and so on.

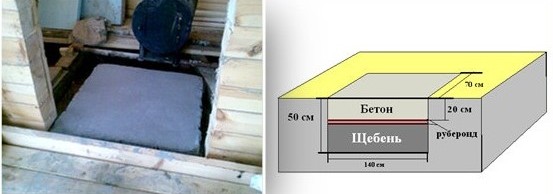

Foundation foundation

Because the foundation of the furnace must be laid simultaneously with the foundation of the bath, then it is necessary to think over its design before the start of construction. If the furnace is metal, then for her this stage can be skipped.

An example of a foundation for a bath

The foundation of a bathhouse is the most difficult part of the process of building a steam room with your own hands. Economically, this stage accounts for 20% of the total cost of construction, and even more in time and labor. On the one hand, it will be calmer to entrust this issue to professional builders - this will be faster in time and will relieve unnecessary tasks. But on the other hand, if the brigade comes across unscrupulous and floods, for example, poor-quality concrete, then you will know about it after at least a year and this error will no longer be fixed.

So, in order to comply with the technology, you will need to know the deformation of the soil and the characteristics of its bearing capacity.

- Determination of soil type. A reliable way to determine the type of soil is the cut method. According to this method, it is necessary to make several pits with a depth of at least 1.5 meters so that soil layers are visible. Depending on the type of soil and using the reference characteristics of the soil cut, you can determine the bearing capacity of the land on the site. Standard - from 2 kg / sq. Cm.

- Determination of the mass of the bath. When calculating it, it is necessary to take into account not only the weight of building materials, but also objects that will stand inside. Knowing these values, you can calculate the load on the foundation, and, accordingly, determine its composition and characteristics. But the best solution is still to seek the advice of a professional.

Further, knowing all the parameters of the furnace foundation (we omit the calculation of the foundation parameters for the entire bath), a depression is made in its location (foundation pit), with a depth of at least 75 cm. Following the sequence, the following layers fall into the pit:

- A layer of sand is poured, 12-15 cm thick. After preliminary watering, the layer is rammed;

- Then a 20-cm layer of crushed brick is filled up;

- In conclusion, the last layer - 10 cm of crushed stone, pre-irrigated, tamped.

On top of the resulting multilayer base, a mold is placed for the steel frame, which is placed inside. Next, in advance prepared concrete it is poured into the mold before reaching the ground level of no more than 10-15 cm. At the solidification stage, be sure to use the construction level so that the surface is perfectly smooth. The mold is taken out after final solidification and level measurements.

Waterproofing

When the foundation is laid, waterproofing occurs in several layers:

- Over frozen concrete roofing material is put;

- Next, a layer of a series of bricks is laid;

- Bricks are covered with the last layer of roofing material.

In between new layers you need to periodically measure the level of all deviations. If you want the stove for the bath house to not cause big problems later, you must follow all the rules for laying the foundation.

Brickwork of the furnace for a bath

For laying the sauna stove with your own hands, you will need:

- refractory mortar,

- refractory bricks of several varieties (often use fireclay bricks, but other options are possible depending on the task),

- elements for blower / doors and handles.

The oven itself can be of several types:

- Kamenka "With a stove" - heating of stones is very long, comes from a stove, which in turn is heated by the heat of burning fuel and almost completely blocks the chimney, during operation it almost does not give dirt or soot.

- Kamenka "On White" - similar to the previous type, but with a partially open chimney, it heats up for a long time - about 12 hours, the minimum amount of dirt and soot;

- Kamenka "On gray" - with the presence of a chimney, the average heating time gives a moderate amount of soot due to the open walls of the chimney;

- Kamenka "On Black" - completely without a chimney, heats up quickly, to use the steam room with such a stove you will have to wait for the complete combustion of fuel;

Drawings are selected depending on the design of the building itself. Fortunately, there are a huge number of their varieties. When the drawing is already approximately selected, it is necessary to determine the type of furnace that will be laid out in the furnace: grate or hairless. The first type gives a high-power flame and intense combustion, but it is much more difficult to maintain it than a hairless one, which in turn is very economical and economically consumes wood fuel. A firebox with grates is also perfect if you have raw or fresh firewood (it will provide a rapid increase in temperature inside the combustion chamber).

If all these stages do not scare you, you are ready to spend a lot of effort and time for designing a man-made furnace - then you can proceed with the laying, along the way, using training aids and accurate measurements. But, nevertheless, this stage is very difficult and without experience in designing such complicated devices it will be very difficult to avoid mistakes. Sometimes you can save just by calling a specialist.

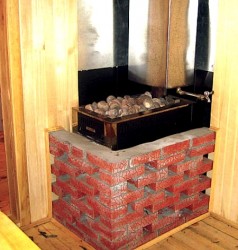

Oven shielding: types and applications of heat shields

Now let's talk more about insulation boards of thermal radiation. In general, the need for their installation is determined by the location of your heater relative to the walls. If it is possible to place the oven at a sufficient distance, then shielding may not be necessary. On average, the safe distance for operating a furnace without shields is 30-35 cm (depending on the heat intensity) if the furnace is brick, and 100 cm if it is metal. But if the bath space is limited, then the screen is what will save you space in a small room and provide a safe rest. First of all, such shields are placed for a Russian bath made of wood. If the walls of the steam room are brick and sheathed with a refractory coating - for the sake of saving space, you can put the stove closer to the wall.

Now let's talk more about insulation boards of thermal radiation. In general, the need for their installation is determined by the location of your heater relative to the walls. If it is possible to place the oven at a sufficient distance, then shielding may not be necessary. On average, the safe distance for operating a furnace without shields is 30-35 cm (depending on the heat intensity) if the furnace is brick, and 100 cm if it is metal. But if the bath space is limited, then the screen is what will save you space in a small room and provide a safe rest. First of all, such shields are placed for a Russian bath made of wood. If the walls of the steam room are brick and sheathed with a refractory coating - for the sake of saving space, you can put the stove closer to the wall.

The design of screens for stoves is quite different, but in general the principle of operation is similar for everyone. The metal (steel, cast iron or other) walls of the screen consist of tubular hollow elements providing high refractory properties.When using a metal shield, the heat radiated by the furnace is reduced by 4 times. They are also very convenient for installation.

A brick screen can increase not only the fire safety of the bath, but also its aesthetic qualities. The most relevant material for laying out the protective casing of the stove is chamotte brick due to its fire-resistant and other suitable characteristics. Depending on the thickness of the masonry, the protective properties of the screen will change. If done in a quarter of a brick, fire resistance will drop by about 2 times from standard, half masonry. Brick shields usually make a few holes in a quarter to half brick to enhance convection currents. The shield itself is placed at a distance of 5-8 cm from the walls of the furnace.

The most popular brick screens in combination with convection-type stoves are most often used for models where the furnace tunnel is remote, that is, with loading firewood from another room. Among other things, on the basis of a brick shield, you can make a fireplace insert.

As a final touch, you can make not only a screen, but also fire-resistant wall cladding (especially if the walls are easily flammable). Often, stainless steel sheet is used as the first layer. In the second layer, you can use any of the following materials:

- Minerit - special refractory boards designed for thermal insulation and protection against ignition of fireplaces, boilers, stoves, etc.

- Asbestos cardboard;

- Basalt cotton wool.

Usually, sheathing is done as follows: the first layer is refractory sheathing, the distance to the wall is 2-3 cm; the second layer is a stainless steel sheet at a distance of 1-2 cm from the insulation. At the same time, the distance to the furnace should not exceed 38 cm (according to SNiP 41-01-2003).

Since the stainless steel can spoil the general appearance of the bath, it is recommended to revet it with suitable fire-resistant materials, such as:

- Brick tile;

- Porcelain tile;

- Terracotta tiles made of baked clay;

- Wild stone (natural stone).

In general, how to make your bath comfortable for you is up to you. The main thing is to immediately assess how much time, effort and money will go to the bath of your dreams, whether to do it yourself or give preference to professionals.