How to choose a grinder for home: 7 tips for choosing an angle grinder

There are such categories hand tools, which sometimes just can not do. This type of angle grinder (angle grinder) or “grinder” refers to, as everyone is used to calling it. Whether it’s a minor home repair or construction work on a summer cottage, independent tile laying or polishing of wooden elements - successfully selected type of grinder will cope with all this. In this article we will give 7 literate tips for choosing a grinder for the home, consider pricing and recommend trusted manufacturers.

1. The principle of operation and scope

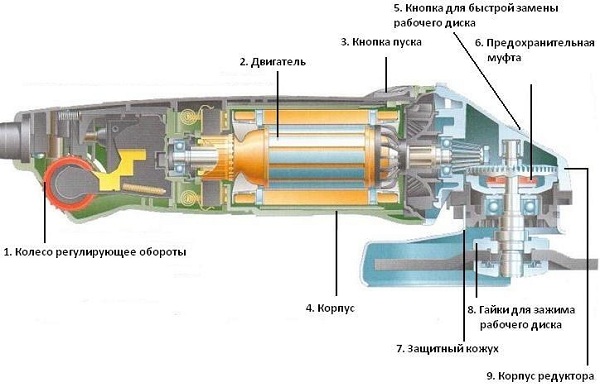

angle grinder - This is an electric hand tool, which is designed for cutting, cleaning and grinding products from materials such as various types of stone, including concrete, metal, wood and others. The device of the grinder is not particularly difficult. However, it is necessary to navigate this issue in order to be able to carry out repairs or preventive cleaning yourself. In a durable plastic case are enclosed essential elements as:

- The wheel regulating turns;

- Engine;

- Start button

- Housing;

- Quick Replace Button:

- Safety clutch;

- Protective cover;

- Nut clamping the working disk;

- Gear housing;

Himself principle of operation It comes down to the transformation of the torque that comes from the spindle connected to the engine using a gear transmission. It is to the spindle that the various nozzles necessary for this or that type of work are attached. The tool body is made of high-strength plastic, which can withstand shock. Just using different types of nozzles, or rather, different types of abrasive wheels, you can perform completely different tasks, which greatly increases the scope of this tool.

Bulgarian applies when necessary:

- Cut or cut tiles;

- Cut metal sheets or rods;

- Cut the strobes in a brick or concrete wall under electrical wiring or water pipes;

- Remove rust from a car body or a layer of old paint;

- Sand wooden or metal surfaces to a high degree of smoothness;

- Strip welds;

- Dull sharp edges with chamfers.

2. Types of grinders

All the variety of this tool can be sorted by type of food. Despite the fact that most of this tool, approximately 95%, are electric, there are four types of power supplies.

Network grinders

The most common type, operating on a voltage of 220V. Have the ability to use discs of various diameters. It is advisable to use them in confined spaces where there is free access to the network or in areas equipped sockets. This is the best option for use in an apartment or in the country. It is a network tool that professional electricians, plumbers and tile stackers use. Depending on the power, there are both professional models and simpler ones.

Network grinders have the following advantages:

- have a high rotation speed;

- are powerful, but at the same time economical;

- for ease of use, there are several options for the dimensions of the case in accordance with the disks of various diameters;

- affordable pricing policy;

- relatively light weight;

- a variety of nozzles that can be used with a particular model;

- Long life with proper use.

TO disadvantages can include:

- limited use due to volatility;

- the power cord during operation can interfere with the process and create inconvenience;

- interruptions and instability of the tool in case of a fall can be observed

- mains voltage.

Cordless grinders

Their appearance and body structure has a characteristic difference from network models. At the end of the tool is a large compartment for attaching batteries. Such grinders are available in modest sizes, and their body serves as the main handle while holding. The size of the disk nozzles does not have such a variety as the previous type and lies in the range of 125-150 mm. The battery used is a 18V lithium-ion battery. To work continuously for a long time with such a tool will not work. It is rational to use it when it is necessary to perform short-term work in an open area remote from access to power supply. For example, in construction fencing along the perimeter of the work site, in case of emergency opening of metal doors or work in suburban, non-electrified houses. Despite some limitations, these models have a number of advantages:

- high speed of rotation of abrasive disks;

- compact dimensions of the body and the tool itself;

- For safe storage and transportation, most of these grinders by default are equipped with a case made of shockproof plastic. Thus, you save on an additional purchase of this item;

- due to its low weight, it will be very convenient to work; it is possible to make precise cutting or cutting of materials;

- most models are equipped with a number of additional protective functions;

- the presence of an additional side handle significantly reduces the level of vibration, which makes it possible to more evenly hold the tool.

Consider the main limitations:

- the period of the tool is limited by the battery capacity;

- Not all models come with a battery. In some cases, it must be purchased separately;

- limited disk size, and therefore a limited list of work performed;

- high price.

Gasoline angle grinders

This type of grinder is clearly distinguished by its appearance. Their case has large dimensions. Inside it is placed a fuel tank and an internal combustion engine. Due to its large size, the tool is equipped with a massive frame-handle for easy holding and an auxiliary handle. Gasoline grinders are equipped with large diameter discs and are used for cutting concrete and iron in places with no access to the electric network. This tool has an increased noise level due to the characteristics of the engine. Work must be done using hearing protection.

Benefits These models are as follows:

- increased power and larger disc diameter;

- fast cutting of large items - pipes, profiles, concrete products;

- autonomous work thanks to the gasoline engine;

- work can be performed continuously with regular refueling of the fuel tank;

- the presence of the stand, which allows you to use the grinder as a complete cutting machine.

disadvantages gas grinders:

- additional costs associated with the purchase of fuel;

- high noise level during the work;

- work only with nozzles of large diameters;

- due to the large dimensions of the tool, it is not always possible to get the cut area in hard-to-reach places;

- in order to avoid overheating of the engine, regular interruptions in operation are required until complete cooling;

- high price.

Pneumatic models

They have the same principle of operation and purpose as the other types of grinders, but differ in their internal structure. Such models do not have an engine, and the rotation of the nozzles is ensured by a powerful stream of compressed air acting on the blades inside the housing. When the blades rotate, the axis on which the disk is mounted is launched. For operation, a valve is used that allows access to the air flow to the internal channel in the housing. Thanks to this structure, pneumatic grinders are the lightest among all possible types. The duration of its work is not limited and can last at least a whole day. To work with such a tool, access to the compressor, which pumps air, or to the air network is necessary. Due to such features, pneumatic tools are not used for domestic purposes. But in the metalworking industry, these models are indispensable. Benefits they have quite significant:

- very low weight;

- due to the lack of engine, overheating of the tool is impossible;

- minimum time of continuous operation is 6-8 hours. It is limited exclusively by the human factor;

- replacement of bearings, valves and other parts will be inexpensive;

- such models can be used in high humidity conditions without any risk;

- high speed;

- the operation of the instrument is completely silent. Sound appears only at the moment of contact with the processed surface.

Disadvantage just two:

- high price;

- the need for additional equipment that will ensure the operability of the tool.

Summarize. For using the grinder at home, of course, the best tool would be a network tool. It is more affordable and has the ability to work with different diameter discs, and even more economical. Having picked up the tool of the right size, you can cope with a ton of tasks. However, if planned construction of a country house or long-term repairs in suburban areas, it is worth considering the purchase of autonomous models that can and fittings chop, and concrete blocks. The choice of type of food depends on the work ahead.

3. Tips for choosing the size of the blade

It is the diameter of the disc that is key factor which defines the scope of work performed by the tool. It is worth noting that the landing diameter for the circles has a standard size of 22.2 mm. But, the larger the diameter of the cutting wheel, the higher the rotation speed and power of the grinder. Minimum the diameter is 115 mm, as much as possible possible - 230mm.

The diameter of the disk is selected depending on the thickness that will need to be cut. Based on the fact that not all, but only the part of the circle protruding beyond the tool can be used as a working one, it is necessary to pay attention to the size of the case. For example, if the case has a width of about 60 mm, then when using a 125 mm disk, it is easy to understand that only half of its surface will work. That is, it will be possible to cut through a material with a thickness of not more than 35 mm, but in reality even less - 30 mm. After some time, the cutting surface of the disc is sharpened, which will significantly reduce this figure. With the help of such simple calculations, the required disk size is selected. But it is strongly not recommended to use circles of larger diameter than allowed by technical documentation.

To make it easier for you to navigate, we will analyze the types of grinders in more detail, based on the size of the disk:

- Angle grinder on the 115 mm - minimum size for the simplest jobs. Most often used for grinding, as cutting this size is very inconvenient. A smaller diameter means less weight, and therefore less power. Weight lies in the range of 1.5-3 kg, and power is not more than 1000 watts.But the "small" grinder has a maximum speed of 10-11 thousand rpm. It is possible to capture both one and two hands. The size of the instrument does not affect the price, and such a compact instrument can have both low cost and vice versa. There are models equipped with many additional features for professional use.

- Bulgarian on the 125 mm - the most popular model. It has sufficient power, optimal weight and size for the convenience of work, affordable cost. In any store, the most extensive selection of grinding or cutting wheels with a diameter of exactly 125 mm. This is the best tool for home use if you do not plan to cut too thick parts.

- Bulgarian on the 150 mm - unlike the previous model, it is not in such demand, although it is an excellent alternative for home use, if not a small, but not a large model is needed. It is convenient to perform both grinding and cutting operations. But many argue that a more convenient solution would be to buy a separately small - by 125 mm and large - by 180 mm grinders. This tool has an average power of 1000-1500 W, an average rotation speed of 8-10 thousand rpm and an average weight of 3-5 kg. "Golden mean" for home craftsmen.

- Bulgarian on the 180 mm - A suitable option for construction work. Depth of cut will make cutting easy bricks (True, it is necessary to incise anyway from both sides), a thick pipe and other elements. This means that performing smaller work with such a tool may not be very convenient.

- Bulgarian on the 230 mm - maximum provided by manufacturers. It is called the "big" Bulgarian. It has a more substantial weight - 5-8 kg, a powerful engine - 1500-2000 W, speed of revolutions - 6-8 thousand rpm. They are equipped with two handles - stationary rear and side with the ability to install on different sides of the case. They have a high cost, which justifies the number of built-in functions. With its help, rough work is performed where the use of force is necessary, for example, cutting metal pipes, shredding walls for wiring, etc. For small works, such models are absolutely unsuitable, even grinding seems unlikely. But with major repairs or construction work, they will be most welcome.

Having analyzed five possible sizes of this tool, it is clear that each has its own advantages and disadvantages. If you are engaged in construction work at a professional level, then the best solution for you would be to purchase two grinders. Small - by 125 mm for precision work and medium - by 180 mm. If you have to repair or construction, then a tool for 150 or 180 mm is suitable.

4. Main tool features

When you have exactly decided which tool size you need, you can proceed to the selection by the following parameters:

- Power grinders are the main indicator of tool productivity. The possible power range varies from 0.5 to 2.7 kW, and the increase in power is not directly proportional to the diameter of the working disk. Choosing a performance indicator follows the same principle as the size - depending on the degree of complexity of the work ahead and their duration. It is clear that using the maximum diameter of the working circle, it is necessary to choose models with a power indicator of about 2 kW in order to ensure high rotation speed and increase continuous operation time. But for small tools with a minimum diameter of the disk, sometimes high power is needed, especially if you have to continuously clean solid welds for several hours. A small tool with a power index of 0.5-0.9 kW is considered household and is quite suitable for a small amount of work, which does not imply a long cutting of pipes or grinding of concrete surfaces.For more difficult work, models with a power of 1 to 1.5 kW are suitable, which are classified as professional. To carry out construction work, it is preferable to have a grinder with a power of 1.3 to 2.7 kW.

- Rotational speed Angle grinder lies in the range from 6000 to 15000 rpm. It is believed that the higher this figure, the faster you can perform grinding work or clean the surface from rust and other contaminants. In practice, this indicator for each tool is selected individually depending on its weight and is optimal. The only thing you need to know is that the angular speed of rotation depends on the diameter of the working disk. Therefore, for large grinders, it is preferable to have a speed adjustment function. When erasing the working edge, this figure must be reduced, thereby normalizing the speed of angular rotation. For domestic use, a tool with a minimum indicator of 6000 rpm is quite enough. If you are planning to build or work, including polishing wooden surfaces or making wooden fencing, you will need a model with an indicator of 7000-11000 rpm. For cleaning car bodies and other metal surfaces, choose a tool with an indicator of 15,000 rpm. Such can often be seen at the service station.

- Weight tool determines the duration of work. Do not forget that when working creates a load on the arms and back. The lightest tools, the weight of which starts at 1.2 kg, is suitable for daily work lasting no more than 4 hours. Average grinders weighing from 3 to 4 kg are suitable for work for 2-3 hours every day. For heavy work, it is necessary to choose larger models that will cope with the task faster and do not require much effort from the operator. Their weight is 6-9 kg.

- The number of handles. Grinders are one-handed and two-handed. It immediately catches the eye when visiting specialized stores. All models have a main handle, which is screwed in at the spindle itself and has the ability to rearrange on different sides of the housing. This makes working with the tool equally convenient for both right-handed and left-handed people. The second handle is either the body itself, or an additional handle at the end. This makes it possible to hold the tool with both hands if necessary. The choice of the number of handles is again based on the nature of the work ahead. It will be equally convenient to carry out cutting work as a tool with one handle, or with two, and it is dangerous to carry out grinding work with a one-armed tool. During operation, the grinder can be heavily drifted and even a physically strong person can hardly keep it. Therefore, choosing powerful models for grinding, look only at two-handed. Grinders for fine grinding of low power can be one-armed. The main handle should preferably have finger protection for large tools and an extension at the top for small ones. This will prevent the instrument from slipping out of tired or sweating hands. The auxiliary handle should have a mushroom shape and, ideally, be able to twist in several positions. This will make working with a grinder as convenient as possible. Both handles should have a rubberized coating.

- Tank capacity or battery. Gasoline models have a tank volume of 0.7 to 1.5 liters. If you have the opportunity to carry an additional canister of fuel with you, then this figure does not matter. Cordless grinders have a battery capacity of 2-4 A / h. Due to this, the spindle rotation speed reaches up to 11000 rpm. Accordingly, the larger the capacity, the longer the tool life. For short-term work, a minimum indicator is sufficient.

- Pressure and feed rate air - for pneumatic models. Speed is essential in maintaining a high speed of revolutions. This indicator reaches from 100 to 540 liters / min.The larger the diameter of the disc, the higher the feed rate. The pressure in this case reaches from 6 to 6.5 atmospheres.

5. Useful extras

More expensive models are equipped with a number of additional features. For instance:

- Case It will be very useful if frequent transportation of the instrument is supposed, and simply for storage and protection from dust, from accidental impacts. The grinder must be securely fixed in special recesses. In the case you can place all the necessary keys and disks.

- System soft start allows you to make the load on the engine minimal. When you turn on the tool, the speed of revolutions will be minimal, gradually increasing. This will protect the internal elements of the gearbox from a sharp blow and from biting the disk in a hard surface. Accordingly, such a tool is easier and more convenient to use.

- Start button lock also greatly facilitates the work. You do not need to constantly hold the power button in a clamped state, from which your hands always get tired quickly. With the help of a small additional button located next to the launcher, you can lock it in the on position.

- Speed adjustment drive - this feature is present in expensive professional models. You can independently set the required rotation speed depending on the work performed and the diameter of the working disk. This eliminates the need to purchase several tools. But if you do not have the skills to work with a grinder, difficulties may arise in the independent selection of modes, and the final result will not live up to expectations. Curved slices and other troubles may result.

- Speed stabilization depending on the load on the disk. Such a function is useful regardless of the user's skills. The tool automatically selects the optimal rotation speed and optimizes the work process. It is very useful when working with heterogeneous materials that have a soft outer coating and a hard core or vice versa. Electronics detects load changes and instantly adjusts speed.

- Dust protection very important when working with concrete surfaces. The gearbox and shaft will be reliably protected from small abrasive particles. The service life of the grinder depends on this. Models with such a function are very expensive, so if you are not involved in construction, then in domestic conditions you can do without it.

- Automatic disk balancing inherent in very high quality tools. The point is that the angle grinder smoothes out the runout that occurs when unevenly erasing the working edge of the disc. This is very useful when polishing. You will notice the difference in working with the tool with and without this function in an hour.

- Opportunity connecting building vacuum cleaner makes the work more comfortable, allows not so much to pollute the surrounding space, the instrument itself and the respiratory tract of the employee. This is an alternative to the built-in dust protection feature at a more affordable price.

- Automatic power off It will be useful in case of power outages. If the light turns off during operation, the machine will work, which will turn off the power of the grinder, and it will not start to rotate when the power is restored.

6. Verified brands and price range

To buy a reliable tool that will last you for many years, you should consider only trusted manufacturers and not skimp on the purchase. After analyzing the reviews of ordinary consumers and professional users, we identified several of the most popular brands:

- Sturm - A proven company co-produced in Germany and China. We can distinguish one of the popular models, which is suitable for home and country use - AG9512P. The diameter of the working disk is 125 mm, while the machine produces a power of 1 kW with a number of revolutions from 4 to 11 thousand rpm.It has a convenient weight - only 2.5 kg and an affordable price - about 3800 rubles. equipped with such additional functions as speed control, soft start, protection against jamming. The handle can be mounted in three different positions.

- Makita - A well-known brand for the production of hand tools. Made in Japan, there are factories in China and Romania. An inexpensive but high-quality model that is suitable for both home and professional use is the 9555 HN. The diameter of the disk is also 125 mm, the power is slightly lower - 0.71 kW. The number of revolutions reaches 10 thousand rpm. This model is lighter - 1.9 kg, but is not equipped with any additional functions. Its cost is about 3600 rubles.

- Metabo, Germany. For more difficult construction work, which involves the processing of stone or concrete, the W 2000 model is suitable. It has a maximum working disk diameter of 230 mm, an impressive power of 2 kW and a weight of 5.8 kg. The number of revolutions is about 6.6 thousand rpm. Equipped with protection against premature start. The price of this model is about 6900 rubles.

- Dewalt - Doesn't even need a description. US production. Among the more powerful and professional models, one can distinguish a medium-sized model - D 28136. The disk diameter is 125 mm, the power reaches 1.5 kW, and the number of revolutions lies in the range from 2.8 to 10 thousand rpm. The tool weighs 2.6 kg. It is sold complete with a case, it has the function of adjusting the speed, soft start and protection against deliberate starting. For a single use at home, it has a high price - 7,800 rubles, but is suitable for professional use.

- Sparky - a real "Bulgarian" made in Bulgaria, where the name comes from. Among the entire model range, the M 850E will be the most suitable for home use, reliable and compact. Its weight is 2.4 kg, the diameter of the working circle is 125 mm. The machine has a power of 0.85 kW and a speed of 3 to 10 thousand rpm. Equipped with speed control and soft start. The price is about 3,700 rubles.

- Among domestic manufacturers can highlight the brand Energomash and its model UShM-9512P, which is suitable for work in an apartment or in a country house. This model is not recommended for continuous operation for a long time, there is a risk of overheating. The tool weighs 2.5 kg, has a power of 0.85 kW and a rotation speed of 3-10 thousand rpm. The diameter of the disc is 125 mm, the price in the region is 3,700 rubles.

- "SPECIALIST"- Another worthy representative of domestic production. The BShU-1050 model has a low cost - only 2100 thousand and a good price / quality ratio. Suitable for small housework. No additional features. The working diameter is 125 mm, the power is 1.1 kW. The number of revolutions is 11 thousand rpm. Machine weight - 2.3 kg.

Choosing the right tool, you should not buy it in obscure places. It is better to go to a specialized store, be sure to check the performance on the spot, carefully examine all the connection points, clarify whether there is a guarantee, and what kind of equipment. Pay attention to the start button, or rather its size. It should be large enough so that even with rude gloves you do not have difficulty turning it on.

7. Rules of operation of angle grinders

Repairing a grinder is quite expensive. To delay this moment as much as possible, it is necessary to handle the tool correctly. Consider highlights:

- Without critical need, do not remove the protective circuit above the abrasive wheel. If the need nevertheless arose, be sure to use safety glasses so that small particles of abrasive do not damage the organs of vision. In addition to your own protection, you need to ensure that the tool itself does not touch anything with unprotected sides;

- Particleboard materials are not recommended to be processed with a grinder, only a hacksaw or a saw;

- When working, you need to hold the tool very tightly.If the disc jams, the grinder may fall out of hands and cause serious injury or malfunction;

- When working with metal surfaces, sparks and small scale are inevitable. It is necessary to protect the skin of the hands and eyes and carefully monitor so that sparks do not get on the wiring or flammable materials;

- When cutting any material, in no case should you press on the subject of cutting in order to speed up the process. It is necessary to press only on the tool and then, not too much.

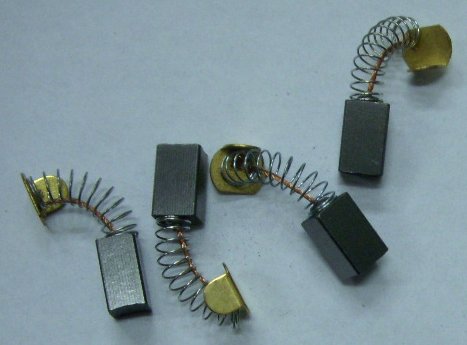

Preventative care also no one canceled. It consists in periodically cleaning and lubricating the tool from the inside, for this part or the entire device is disassembled, dust is blown out and surfaces that need lubrication are processed. Replacing small parts that wear out quickly is very simple. But if you do this in a timely manner, you can protect more responsible and expensive parts from wear and tear.

If the device refuses to start after pressing the button, you do not need to immediately try to disassemble it completely. Start off problem identification costs from the simplest places. For example, to begin with, check the power cord, perhaps a strong bend has formed somewhere, then replacing the power cord will solve the problem.

If the wire and plug are not damaged, then it may be the trigger. It must be disassembled and cleaned, or completely replaced. If too much construction dust has accumulated inside the appliance, this can also cause a failure. To eliminate it, it is often necessary to replace brushes that are so dirty that they simply no longer receive electric current. If this does not help, then you should seek the help of a specialist, otherwise subsequent repairs without proper skills can only aggravate the situation.

If this does not help, then you should seek the help of a specialist, otherwise subsequent repairs without proper skills can only aggravate the situation.

Hello!

Among the advantages of pneumatic grinders are listed: “high speed; the operation of the instrument is completely silent. ”Let me disagree. Whatever the speed, the linear speed of the wheel should not exceed 80 m / s. (It is written on all abrasive wheels!) And the second. Pneumatic angle grinder in the industry is called the “marmoset”, due to the characteristic squeal of the turbine. Silent air motors have not yet been invented.

Sincerely.