10 tips for choosing tiles for the pool

Arrangement and subsequent private pool decoration - This is a complex process, including many time-consuming steps, each of which requires certain knowledge and a responsible approach. Despite possible difficulties, most of us do not deny ourselves the pleasure of having our own own swimming pool, and the most practical ones try to do the whole range of work on their own. Be that as it may, the most common question is choice of finish. In this article we questionchoosing tiles for the pool,one of the most popular and beautiful types of cladding. We will figure out what requirements the selected material must meet and how to perform independent cladding.

1. What should be the tile for the pool?

Before you start choosing a tile that is suitable for design and color, you should know that plain tile, which is widely used for decorating bathrooms and other rooms, absolutely not suitable for swimming pools. This is due not only to the fact that it does not have a very suitable composition, but also to its size and other characteristics.

During operation, the tile, which is lined with a bowl, will experience constant loads. Water in the tank and other external factors will exert enormous pressure on it. Plus, an important factor is the location of the pool - whether it is equipped in the open air, or indoors. It is also worth considering the fact that it will be the tile play the role of waterproofing, because concrete bowls are not able to maintain integrity and tightness with constant contact with water. Concrete refers to porous materials, which are able to absorb moisture, weaken in this regard and form cracks.

Given all of the above, to the tiles for finishing the pool put forward very clear and strict requirements, which must be adhered to:

- One of the main criteria is low coefficient of water absorption. This is an indicator that characterizes the ability of a material to absorb moisture. In our case, it should not exceed the value of 6%. Why is it important? With prolonged contact with water, a material with a high absorption coefficient will fill its structure with excessive moisture in a very short period of time. This will lead to its internal destruction, possible deformations under water pressure and premature cracking. Accordingly, there is no question of tightness in this case;

- Resistance to aggressive chemicals. During the cleaning of the pool and its disinfection, mainly detergents are used, in which chlorine is present. The surface of the tile should not react with such substances and withstand their regular effects without losing their original appearance;

- Also, the material must have increased impact resistance;

- Tile for finishing the pool, which is located on the street, must be frost resistant and immune to sudden changes in temperature;

- Availability anti-slip effect. This is a mandatory item on which the safety of using a swimming tank directly depends. Particular attention is paid to hazardous areas, such as steps, descent into the water and the area around the pool where water constantly gets. The facing material may have a relief or rough surface;

- High strength, which will withstand significant pressure of the water volume;

- Strange as it may sound, but the tile must be flexible. Excessive water pressure should not cause internal stresses in the material, but should be compensated. This will allow the finish to last much longer;

- Non-porous surface. A material with a porous surface structure is absolutely unsuitable for finishing pools. In addition to absorbing water and gradually breaking down, the pores will serve as a breeding ground for bacteria. mold and other microorganisms. Because of this, the walls can become covered with mucus, which will not only make them very slippery, but will also pose a health hazard.

Only that kind of tile that will meet all the requirements can provide reliable and durable waterproofingas well as security.

2. What to consider when choosing tiles for the pool

Considering the material requirements that we listed in the previous paragraph, you should definitely choose pay attention to following points:

- Choose only the material whose surface is absolutely smooth, without visible pores;

- Each manufacturer who specializes in the production of just a variety of tiles for pools, puts on their products appropriate marking. It indicates for which surface the material is intended - for finishing the bottom, side walls, steps under water or the territory adjacent to the pool, etc. All of them may differ in terms of water absorption and anti-slip class. This must be taken into account;

- The tile, which is designed for finishing wet areas, according to European standards, is divided into three slip classes - A, B, C. According to this division, the material is marked with Latin letters, meaning the minimum angle of inclination. Thus, class A implies that on a wet surface with bare feet you can stay at a maximum angle of inclination equal to 12 degrees. Class B means a tilt angle of 18 degrees, C - 24 degrees;

- Class A Material recommended to lay on footpathswhere the humidity level is minimal, in the locker rooms or at the bottom of the bowl, if its depth exceeds 80 cm;

- Class B suitable for laying paths around the perimeter of the pool where people walk barefoot, for laying on steps of stairs whose width does not exceed 1 meter and which are equipped with handrails on both sides, for facing children's pools or bowls whose depth is less than 80 cm;

- Class C also used for laying around the pool and lining the sides. It is not recommended to use for facing steps or slopes;

- Be sure to pay attention to the shape of the material. The edges of the tiles should be rounded in the form of an arbitrary radius. This minimizes the risk of injury by hitting an acute angle;

- An important role is played by material size. The larger the tile, the greater the likelihood of its destruction under the influence of water pressure. The maximum allowable fragment size is 125 × 245 mm. If the bowl has the correct rectangular shape, tile lining with a size of 150 × 150 mm is acceptable. For finishing complex radius surfaces, it is better to use smaller elements. Working with them will be much more convenient. The sizes of elements for finishing custom designs range from 20 to 100 mm, both in width and in length;

It is recommended to choose one of the following types of tiles.

3.Clinker tile for pool lining

Brick tile most often used for minimize costs. The name comes from the German word "klink", which means a durable, waterproof refractory brick. It is an environmentally friendly material with a very long service life. Like ceramic, it is made from clay dough with a minimum amount of additional impurities by extrusion. In this regard, the clinker may have small deviations from the size. Taking into account possible deviations in geometry, it is necessary to stack elements not with a minimum gap between each other, but with a seam with a width of at least 5 mm. To give a characteristic shade, coloring oxides and fluxes are introduced into the composition. The surface of the tile may be glazed or unglazed. When baking, the glaze penetrates even into the smallest pores of the structure and seals them, making the material immune to moisture.

The main the benefits Material are:

- Clinker water absorption coefficient is almost zero, comparable to glass;

- In addition, the indicator of wear resistance and abrasion increases;

- Such a tile will not crack or burn out in the sun;

- The material is not afraid of sudden temperature changes and its minus indicators, which makes the clinker an ideal material for facing outdoor pools;

- The tile is able to withstand prolonged monotonous loads;

- The choice of colors and shades is quite diverse;

- Some manufacturers claim that the material has virtually no life, and give a guarantee of up to 100 years.

It is recommended to use glazed tiles for finishing the pool bowl, and for the adjoining territory you can use tiles without glaze, which has anti-slip properties.

When choosing a clinker, it is imperative to clarify the availability of a hygiene certificate that meets national quality standards.

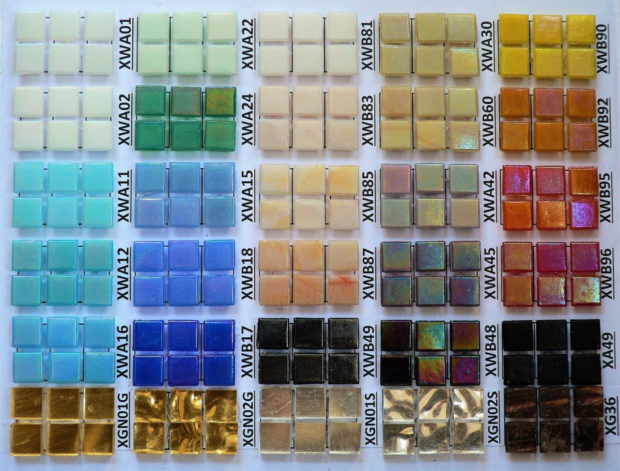

4. Finishing the pool with glass mosaic

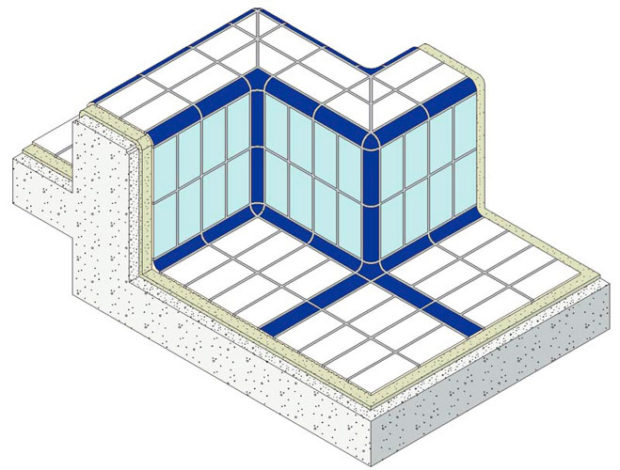

Glass tile has the lowest rate of water absorption. This makes it an ideal facing material, but more expensive than clinker. The main component in the production is quartz sand, in which various oxides are added to give a certain shade. The vast majority of glass tiles are mosaic. The form and the size A single element can be very diverse. But most often you can find sheets measuring 30 × 30 or 60 × 60 cm, on which small squares are pasted.

Mosaic, whose fragments are hexagons, gained great popularity. Such cells look more interesting and unusual. A big advantage of mosaics over tiles is the presence of a flexible base in the form of a grid. Although the installation process itself can hardly be called quick and easy, such a solution greatly facilitates the work. In addition, due to the small size of individual elements, complex surfaces of radius shape can also be tiled using mosaics. It is possible to divide the sheets into smaller pieces and create a colorful, detailed panel at the bottom or on the walls of the pool. In addition, glass mosaic has the following advantages:

- Long period of operation;

- Heat resistance and frost resistance;

- Immunity to chemicals;

- Absolutely smooth surface without pores, which can be breeding sites of harmful microorganisms;

- Increased impact resistance, which is achieved by additional firing of each individual element;

- A diverse and extensive color palette;

- Color fastness to ultraviolet radiation;

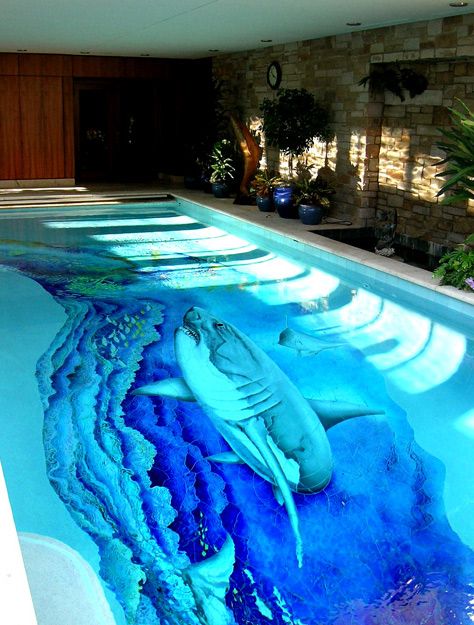

When dyes are added to the composition during manufacture, each individual tile can have its own individual shade, which most clearly manifests itself under water. This creates an internal flicker effect and a stunning optical illusion. The water in the pool begins to overflow and flicker.

5.Porcelain tile for swimming pools

Another suitable material for decorating swimming tanks is porcelain tile, which belongs to a variety of ceramic. It got its name because of its similarity in color and composition to real china. It is made of white clay with the addition of feldspar, kaolin and quartz. Oxides of various metals are introduced into the mass to impart the desired shade. Next, the finished mass is pressed using special presses or extruded through an extruder. After that, high-temperature firing must be carried out at a temperature of about 1300 degrees. This processing method allowed me to achieve the melting of even the hardest and finest particles in the composition and their sintering with each other. The structure of the porcelain tile is very uniform and dense, which helps to increase indicators such as strength and durability.

The end product has many advantages:

- The surface has a very low coefficient of water absorption. In appearance, it resembles glass - it is also smooth and shiny, i.e. porcelain tiles do not need to be specially glazed after heat treatment;

- Due to this, the material is impact resistant. Under the influence of the impact, the tile will not be covered with small cracks and will not chip;

- Increased frost resistance makes it possible to use this type of ceramics for finishing outdoor pools;

- Resistance to chemical agents will greatly simplify the process of pool care and cleaning;

- The surface of the porcelain tile is not a suitable environment for the habitat or propagation of harmful microorganisms;

- Also, the material is heat-resistant, which makes it possible to lining therapeutic pools with hot water.

6. Finishing the pool with ceramic tiles

Ceramic tiles are also widely used for decorating pools. Moreover, with its help, you can perform the lining of all surfaces - and steps, and side walls, and the bottom. It should be noted immediately that the composition of the material used for swimming pools differs from the composition of ceramics, which is used to decorate bathrooms and other rooms. Components are introduced into the mass that significantly increase the density and hardness of the tile and its other characteristics.

The most significant the benefits ceramics are:

- Practicality;

- Long term of operation;

- The surface has high water repellent properties;

- Increased strength;

- Refractory properties;

- Hygiene

- Safe operation of the pool due to the presence of rounding radii at the edges of the tile;

- Easy care due to absolutely smooth surface;

- A wide selection of colors.

Ceramic tiles are available both in the form of individual fragments, and in the form of mosaics. Both varieties have high anti-slip properties.

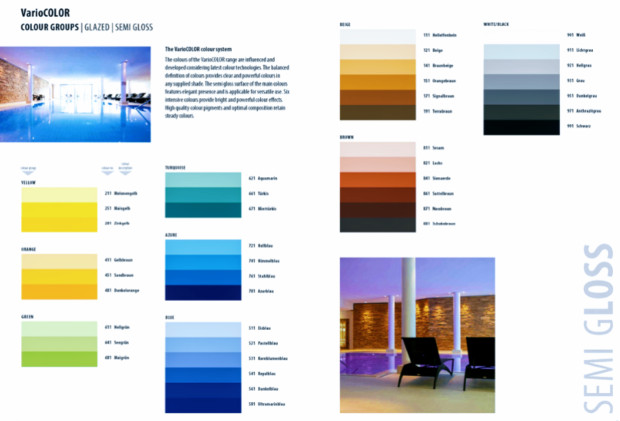

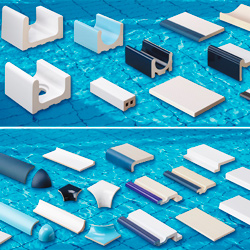

7. Pool tile manufacturers

The range of tiles for swimming pools is quite diverse. The vast majority of manufacturers produce products that immediately divided into collections. Each of them will definitely include a tile of a background shade, one or several decor options to choose from, which can be a whole colorful panel, and a set of basic shaped products. The presence of the latter will greatly facilitate the finishing of complex surfaces such as places around handrails, corners, gutters for draining water, etc. When choosing a particular shade, do not forget that if you facing the ends of the steps or the edges of various complex surfaces with a darker or brighter shade, they will become much more noticeable, which reduce the risk of injury. Basically, the entire range of finishing materials is represented by a spectrum of blue, blue and green shades and decors on a marine theme. However, there are more interesting options - shades of black and panels with abstract drawings.

When choosing a particular shade, do not forget that if you facing the ends of the steps or the edges of various complex surfaces with a darker or brighter shade, they will become much more noticeable, which reduce the risk of injury. Basically, the entire range of finishing materials is represented by a spectrum of blue, blue and green shades and decors on a marine theme. However, there are more interesting options - shades of black and panels with abstract drawings.  To the most popular manufacturers tiles in the Russian market, which have managed to win many positive reviews, include the following brands:

To the most popular manufacturers tiles in the Russian market, which have managed to win many positive reviews, include the following brands:

- Porcelain tiles for swimming pools from a Turkish manufacturer called "SERAPOOL" has a water absorption coefficient of only 0.1%. Tiles are available with absolutely smooth as well as with a raised surface. The plasticity index of the material reaches an indicator of at least 27 square mm, which allows you not to worry about the appearance of cracks during filling the pool with water. The products have certificates of compliance with international quality standards Q 9001-2000 and ISO 9001 and are recommended for facing private or public swimming pools, both indoor and outdoor. The products are characterized by a wide variety of decor options;

- Trademark "Floor Gres" (Italy) from the leading manufacturer of the Florim group is one of the leading manufacturers of tiles for pools. The company has been presenting its products since 1962. During this time, she managed to achieve the highest quality, which meets international standards F.I.N. and F.I.N.A .;

- German brand Interbau Blink specializes in the production of ceramics for facing industrial, sports and private pools. In total, the manufacturer’s catalog contains 7 varieties of clinker tiles and 40 types of ceramic. Fans of non-standard color solutions will surely find a suitable option for themselves among the extensive color gamut;

- Another German manufacturer Agrob Buchtal offers over 70 collections of tiles for swimming pools. The company is engaged in the production of elite finishing materials that have no analogues. Technologies are regularly improved, which improves product quality. Specialists managed to develop a unique antibacterial coating for tiles, which prevents the formation and reproduction of bacteria and microorganisms, simplifies surface care. Among all the variety you can find material for the decoration of indoor sports pools and outdoor pools and small private structures;

- Among domestic manufacturers can be noted the Russian plant "Falcon", which, among other things, produces tiles for swimming pools. It is characterized by high strength indicators, is not subject to cracking, does not crumble, does not corrode.

8. Adhesive requirements

Not only the tile itself, but also the adhesive composition must be selected properly. After all, only comprehensive selection all materials will create a truly reliable waterproofing. Recommended for each type of tile. different glue. The choice should also depend on the base material. Pay particular attention to requirements which are put forward to the composition:

- It must have a high level of adhesion and ensure reliable fixation of the lining. Moreover, this indicator should remain unchanged not only during finishing work, but also after complete drying. For tiles, adhesives with adhesion of 1 MPa or more are recommended, for mosaics - at least 2.5 MPa;

- To be flexible in order to remove and not accumulate internal stresses associated with constant pressure of the water volume and other deformations;

- Demonstrate resistance to constant exposure to the aquatic environment.

- Possess inert properties. Given that water contains various disinfectants, which are usually produced on the basis of chlorine, the adhesive should not react with such components. When cleaning pools, the chemicals used should not corrode glue;

- For outdoor pools, it is important to choose compounds that have increased frost resistance and heat resistance. The water temperature in such tanks can range from +15 to + 30 ° C, and in winter, after the water is completely drained, all finishing materials freeze.Such differences should not lead to a loss of the adhesive properties of their original properties, otherwise all waterproofing will be unsuitable for further operation;

- It is also necessary to choose formulations with antifungal properties. If this is neglected, over time, the seams absorb a large amount of moisture and become the site of the formation and propagation of a harmful fungus.

It is best to give preference to latex-based mixtures. Average consumption adhesive mixture per 1 sq.m. with a layer thickness of 1 mm is 1.4-1.5 kg. But do not take these numbers as accurate when calculating the required amount of glue. After all, all the data are given on the basis that the conditions of use are close to ideal. That is, your surface is absolutely flat, humidity and temperature correspond to those indicated on the package. In practice, this does not happen. In addition, an important role is played by what and at what angle the adhesive is applied, how high the teeth of the spatula-comb, etc. actual consumption closer to 2.3-7 kg. on 1 sq.m.

9. Glue producers

To be sure of the quality of the purchased products, you need to give preference to brands that are widely known and have been producing their products for several years. To adhesives that well myself recommended according to reviews of ordinary consumers and finishers, the following items can be attributed:

- Ivsil aqva - waterproof tile adhesive, which is made on the basis of high-quality cement with the addition of fractionated sand and polymer additives. Specially designed for the decoration of pools, fountains and other water tanks. It is highly resistant to hard chlorinated water. Designed for continuous contact with the aquatic environment. It has frost resistance. It is suitable for use on concrete, brick, cement substrates, as well as on top of old tiles using the tile-to-tile laying technology. Ivsil Aqua glue can be used to lay ceramic tiles, slabs made of natural stone, porcelain tile;

- Ceresit - a well-known brand that produces several compounds designed specifically for lining pool bowls with various types of finishing materials. For laying ceramic tiles, a frost-resistant mixture based on a polymer-cement base Ceresit CM 117 or Ceresit CM 17 is recommended. When lining with a glass mosaic, it is better to use a polymer-cement composition Ceresit CM 115. All of the above items have water resistance, elasticity, increased whiteness of the finished seam;

- Eunice Pool - adhesive composition based on high-quality cement with additives that improve the quality of the finished mixture. It is specially designed for laying porcelain stoneware (no more than 60 × 60 cm in size), mosaic tiles, tiles, ceramics and plates based on natural stone on the horizontal and vertical planes of water tanks. Recommended for work with complex substrates - old tile base, heated surfaces. Suitable for both outdoor and indoor use;

- Founces Belplix T-16 whether T-17 - reinforced tile adhesive designed for laying slabs made of marble, natural or artificial stone, porcelain stoneware, ceramic tiles, glass tiles or mosaics. It is applied to any substrates - concrete, brick, cement plaster, old tiles, cellular concrete. It has high adhesion, frost and water resistance. It has a white color, which allows you not to worry about the color change of the tile after installation. It is used for indoor and outdoor use, when lining bowls of artificial reservoirs and pools. The same adhesive can also be used as a grout.

10. What should be the grout for the pool?

An equally important element of reliable waterproofing is joint filling mixture. The most commonly used grout for pools two-component epoxy mixture. She must possess the following qualities:

- Water resistance;

- Resistance to chemicals;

- Durability;

- Elasticity;

- Antibacterial effect.

Wide application received the following grouting compositions:

- Ivsil fuga - It is made on the basis of white cement, a complex of polymer additives and a special filler. It is used for grouting joints with a width of 2 to 6 mm between tile, ceramic, mosaic, marble tile, both on walls and on floors. Suitable for both dry and wet rooms and outdoor applications. Ivsil Fuga has high elasticity, strength, water resistance, frost resistance and ease of use. In the finished form, the grout fits snugly to the edges of the finishing material. The color of the mixture is bright white. After drying, the seams are easy to clean and do not lose their original color. It does not require additional use of protective equipment, which makes the finishing process more economical;

- To the company for trademark tile adhesive Ceresit recommended grouting compositions of a similar manufacturer. Together with mixtures of CM 117 and CM 117 and CM 115, it is desirable to use a hydrophobic, frost-resistant and waterproof grout on a polymer-cement base Ceresit CE 43 or an epoxy composition Ceresit CE 44, Ceresit CE 47 or Ceresit CE 48;

- Kale fugapool - Troweling mixture of a Turkish manufacturer. It is a one-component cement-based elastic composition. It is used to fill joints 1-6 mm thick between floor or wall tiles of any sizes, mosaics, marble, concrete tiles. It prevents the formation of mold and various bacteria due to the presence of fungicidal and antibacterial additives. Provides a high level of elasticity and waterproofing, is not subject to fading and cracking, quickly sets, is presented in 9 colors. It is used to decorate the bowls of pools, saunas, Turkish baths, showers and other wet rooms.