Types of waterproofing materials used in construction

This article will talk about types of waterproofing and their purpose. The modern construction market is represented by many options for waterproofing materials, which are designed to effectively protect the foundation, roof, walls, building floors from the harmful effects of groundwater moisture, precipitation. The protective work must be carried out qualitatively using that waterproofing, which should be used in each individual case according to the rules of construction work. Each type of waterproofing has its advantages and disadvantages, can be used in various construction works. Let's take a closer look at each type of modern protective materials that are used today.

This article will talk about types of waterproofing and their purpose. The modern construction market is represented by many options for waterproofing materials, which are designed to effectively protect the foundation, roof, walls, building floors from the harmful effects of groundwater moisture, precipitation. The protective work must be carried out qualitatively using that waterproofing, which should be used in each individual case according to the rules of construction work. Each type of waterproofing has its advantages and disadvantages, can be used in various construction works. Let's take a closer look at each type of modern protective materials that are used today.

Painting waterproofing

Painting waterproofing is waterproof film, which is formed by applying liquid or plastic materials to the surface, such as bitumen (the most common waterproofing material), mastic or special paint and varnish, which have the appropriate properties, that is, resistance to moisture.

Painting waterproofing is waterproof film, which is formed by applying liquid or plastic materials to the surface, such as bitumen (the most common waterproofing material), mastic or special paint and varnish, which have the appropriate properties, that is, resistance to moisture.

Bituminous mastics have different fillers - lime, asbestos, talc, which will make waterproofing quality and guarantee capillary moisture protection in a wall or floor of a building structure. Modern waterproofing paints or varnishes have synthetic resins and plastics in their structure, which will also create excellent protection against wet environments. The main types of paint waterproofing material are bitumen, rubber, acrylic, polyurethane and silicone mixtures.

Drawing bituminous painting waterproofing

To apply bituminous hot mastics, the mixture should be heated to 170 degrees Celsius so that it is easily applied and penetrates well into all cracks and bumps through which moisture can penetrate. For cold mastics, heating is not required, they immediately ready for usebut cost more than the first option. Cold mastics require heating at ambient temperature + 5 degrees. They are made from furyl, epoxy, perchlorovinyl and other resins on a synthetic basis.

Before carrying out waterproofing with bituminous mastic, the surface should be treated with a composition of one part of bitumen itself and three parts of white spirit or gasoline. Then composition applied by roller, brush or faster using a spray gun or spray gun. Painting waterproofing is also considered a flame spraying method, in which the coating is applied in at least two layers with a time interval of about 15 hours. The thickness of the bitumen should be 2 millimeters.

Waterproofing waterproofing

This type of waterproofing combines two types at once - it is painting protection, and actually gluing, therefore it has great efficiency, perfectly protecting a brick, concrete, metal and other surface. Gummy waterproofing means covering the surface roll or sheet materialssuch as roofing material or extruded polystyrene foam, which are glued to bituminous mastics of the cold or hot application method.

The main type of pasting materials is roll waterproofing, which is represented by a huge selection in modern building supermarkets designed for various waterproofing works. The most affordable roll material is roofing material.

Installation of gluing waterproofing

When carrying out gluing waterproofing, bitumen mastic is used, and not bitumen-rubber. It is necessary to paste the rolled material in several layers, while maintaining a certain interval, allowing the layer to dry. One of the types roll materials are foil isol, metal isol, hydroisol, glass bit, reinforced asphalt mats, polyethylene or polyvinyl chloride films. Also, glass Ruberoid, Isol, Brizol are used.

When carrying out waterproofing works with gluing materials, it is densely rolled out and glued with bitumen or similar mastic, connecting the edges with an overlap of 10-15 centimeters. Last layer required covered with bitumen mastic hot type and if possible close with a brick or other wall. On the foundation such waterproofing can be strengthened by dipping clay.

Coating waterproofing

This waterproofing is a different liquid compositions of mastics and solutions (sludge) to create a seamless continuous waterproofing layers. It can be one or several layers depending on the required degree of protection. it durable waterproofingwhich is resistant to physical and mechanical stress, has good resistance to aggressive chemical and aqueous media. It is also flexible enough so that no further cracking occurs under the influence of weather conditions or uneven rainfall at home.

This waterproofing is a different liquid compositions of mastics and solutions (sludge) to create a seamless continuous waterproofing layers. It can be one or several layers depending on the required degree of protection. it durable waterproofingwhich is resistant to physical and mechanical stress, has good resistance to aggressive chemical and aqueous media. It is also flexible enough so that no further cracking occurs under the influence of weather conditions or uneven rainfall at home.

Classification of coating waterproofing can be in two main groups - these are mineral and bitumen masses.

- In the first case, it is a cement-based mixture (white or gray Portland cement) with special polymers and granules. They are supplied in the form of a dry powder, which is diluted with water in certain proportions.

- In the second case, the basis of the waterproofing mixture is bitumen, which is covered with a layer of at least 4 millimeters and is additionally reinforced with the corresponding reinforcing mesh.

Application of coating waterproofing

If you use seamless cement waterproofing, then such a protective coating can withstand, quite high pressure in 7 atmospheres, which is equivalent to diving to a depth of about 70 meters. It is often used for waterproofing. poolsthat require good protection from water and in basements, to prevent moisture from entering the house or stop the active flow. It can be applied on different substrates made of concrete, cement or bricks.

Depending on the type of material used, a hot or cold coating is used when waterproofing the surface. You should know that bituminous mastics and sealants on the same basis are good insulate dry surfacebut have toxicity that should be considered. If you do not want to use toxic waterproofing, you will have to increase your budget and purchase two-component polyurethane mixtures that are free from this drawback and completely non-toxic.

Stucco waterproofing

Depending on the materials used, plaster waterproofing can be divided into three subspecies.

- First -cement plaster, which is applied to the surface with a layer with a thickness of 5 to 40 millimeters. The application of cement-sand mortar with the addition of water repellents or mineral fillers is done in layers. The solution is mixed in a ratio of 1 to 1 or 1 to 2. The total thickness of the plaster is a durable waterproofing layer.

- Second -asphalt plaster, which is applied in a layer of up to 4 millimeters in several layers, usually 2-3 layers, but more can be. The coating is a protection of hot or cold mastics. After application, create brick protection layer or concrete layer when creating vertical waterproofing. With horizontal waterproofing, 2 layers of 7-8 millimeters are created, which is protected by a screed of cement mortar or concrete.

- Third - cast asphalt waterproofing. represents hot mastic solution, which is poured into the cavity between the protective wall and the insulated surface. This is with vertical waterproofing. With horizontal moisture protection, the solution should be leveled on the surface, and then additionally coated with a cement screed.

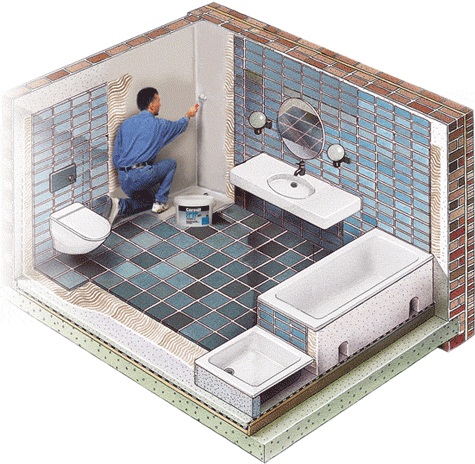

The use of plaster waterproofing

Most often, plaster waterproofing is used in places where a large amount of moisture is concentrated. For example, very often pools are waterproofed with this particular type moisture protection. Such waterproofing is also very effective in the bathroom or other rooms with a high level of humidity. In addition, it is used as an antifiltration and anticorrosive protection of inclined and vertical surfaces.

They also use plaster waterproofing on concrete, metal or brick surfaces. Layers of such protection are applied from the side where it comes from hydrostatic pressure. If this pressure is variable, then waterproofing should be fixed between rigid supporting structures, for example, brickwork.

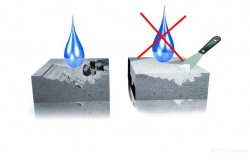

Penetrating waterproofing

This type of waterproofing provides good waterproofness. concrete structures. A feature of these waterproofing materials is that they can be used both at the beginning of the construction process, and at the final stages of work. Further penetrating waterproofing can be used for recovery of lost properties water resistance of building structures. Compositions are a structure that penetrates deeply into a surface with a porous structure.

This type of waterproofing provides good waterproofness. concrete structures. A feature of these waterproofing materials is that they can be used both at the beginning of the construction process, and at the final stages of work. Further penetrating waterproofing can be used for recovery of lost properties water resistance of building structures. Compositions are a structure that penetrates deeply into a surface with a porous structure.

In addition to penetrating into the surface and creating a moisture barrier, this waterproofing has the property of preventing corrosive processes in reinforcing structures. Penetration compounds may also resist chemical attack and significantly increase the surface resistance. Significantly increases the service life of building structures that have been treated with penetrating waterproofing. This allows you to solve several problems at once when protecting against moisture.

The use of penetrating waterproofing

An example of waterproofing with penetrating waterproofing is the application of a solution of Portland cement and fine sand, to which chemically active ingredients have been added, stimulating crack healing process and their prevention. After applying this protective layer to concrete the surface of the wall or floor, the strength of the surface increases by a rather impressive 20%.

In addition, a feature of penetrating waterproofing is resistance to frost. It does not require surface priming, leveling or perfect dryness. Also, a protective wall or additional backfill is not required. This waterproofing is pretty universal and has many advantages over others, due to the property of strengthening and waterproofing the surfaces of walls and floors without the need for reinforcement with additional structures such as metal reinforcing mesh.

Sprayable waterproofing

The composition of the waterproofing mixture is sprayed using a spray gun or a special airless spraying unit. The composition that is sprayed on the surface is liquid rubber or another similar acrylic composition sprayed onto absolutely any surface. Such waterproofing is now quite popular and quite affordable for small budgets.

Due to the growing demand for this waterproofing material, they began to produce a very durable sprayed waterproofing on polyurethane basedacrylic or traditional bituminous compositions. Waterproofing has a long service life, which will undoubtedly interest people who want to protect their home as much as possible from moisture and the further destruction and corrosion of walls, floors or foundations.

Application of spray waterproofing

The unique properties of sprayed waterproofing allows you to maintain their anti-corrosion properties and protection against moisture for 50 years, which is an impressive period and gives a great advantage over other types of waterproofing. The drying time of this composition on the surface is about 10-20 hours, depending on the thickness of the layer that was applied. The versatility of this waterproofing gives it an extensive scope, thanks to its resistance to aggressive environments. These materials have good soundproofing and anti-corrosion properties.

This waterproofing is used in the manufacture and repair of construction cranes, protecting pipelines from breakthroughs and creating an additional layer of protection. The scope of use also includes the processing of machine parts in the relevant industries and creation of a protective layer on the decks of ships. In addition, waterproofing spraying with a color compound at sports fields is used. This very effective waterproofing spraying will protect the structure even from a high level of humidity in various conditions. Versatility and good protection give advantages over traditional waterproofing.