9 pool finishes

Many owners of private houses and summer cottages are eager to establish a pool in the adjacent territory. Inflatable options are unreliable and can not be compared with the usual ones, they are suitable only for children's games. An adult needs a spacious and deep object in order to swim with comfort and enjoyment. The best from this point of view are concrete pools. They are durable, reliable, can have any shape and size. To enjoy such a pool, you will have to spend a lot of time, effort and money, and in order for the result to please the eye, it is important to properly finish the pool. We figure out what materials are used for this, and what preliminary work will have to be done. Everything is not as complicated as it might seem at first glance.

No. 1. Creating a pool bowl

You can handle the decoration of the pool yourself if you have free time and skills. It is much more difficult to independently fill, install filters, a pumping system, utilities and other important details. Before creating a structure, it is necessary to investigate the type of soil and the presence of groundwater. Not everyone can carry out such procedures independently. In this case, it is better to entrust the process of preparatory and finishing work to specialists who have extensive experience in decorating pools and know all the nuances of the process. For example, the POSEYDONSTROY company has been doing this for more than 15 years and has many good reviews from customers and a large number of examples of work that can be studied on the company's website.

Pool shape is selected individually, but it is better to dwell on an elongated structure. The optimal aspect ratio is 2 to 1. For a comfortable stay, a pool length of 6 meters is suitable, which can accommodate even a large group of adults or children.

Pool organization divided into several stages and includes foundation pit preparation, formwork and casting. After this, a concrete or brick bowl is formed, at the same time engineering communications are established.

In suburban areas, the following types of pools are used:

- from reinforced concrete - the ideal of strength and reliability, which is achieved due to the absence of joints on the bowl. First, the excavation digs, then the formwork with reinforcement is installed, after which concrete is poured. A similar design transfers solid loads, including the pressure of a large volume of water, so that even the largest pools of any shape are made of monolithic concrete;

- brick wall pool arrangement is much easier. In this case, only the bottom of the bowl is made of reinforced monolithic concrete, the walls are built of bricks. Use only Red brick, wall thickness - at least one brick. Such a design will not withstand a large volume of water, maximum 40 m3, length less than 6 m, but if the pool is being built in the country, then this should be enough;

- frame pools do not need finishing, their installation will take less time and money, but in terms of size they are limited. Seasonal structures are installed on the site, do not require the preparation of the pit, but for the winter they must be dismantled. Frost resistant frame pools go deep into the ground and look almost like real concrete bowls. They do not require decoration, can be of almost any size, but their service life is limited - up to 10-15 years;

- inflatable pools also do not require finishing work, but to call them a serious adult option is difficult. Neither swimming normally, nor jumping, nor having fun in such a bowl will work. The size of the pools is limited, as is the service life. This is an option for children.

If you want to swim and swim normally, you will have to dig a pit and pour concrete. And if many, indeed, entrust these tasks to specialists, then they often take matters into their own hands. Facing a pool bowl is not the same as making a repair in a bedroom. This is a more subtle and demanding process. You can’t just take it and start finishing right after the concrete has gained strength, or when the mortar has frozen in brickwork. You will have to first perform the plaster and waterproofing works, and only then - lay the tile or mount the film.

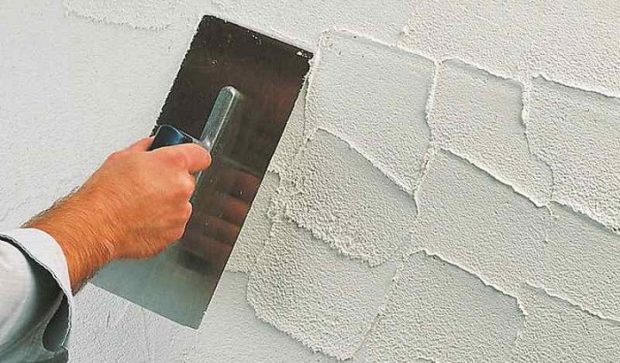

No. 2. Stucco pool bowls

After removal of the formwork, numerous irregularities and influxes of concrete are often found. Masonry also cannot be absolutely even. Such a surface is not suitable for decoration - it must first be carefully leveled with plasters. The durability of the cladding and the structure itself depends on the quality of the work. The plastered surface should not have cracks or other defects, one roughness with an area of not more than 1 mm is allowed2 on 4 m2 the surface of the bowl. The walls and bottom should be perfectly flat, a deviation of 1 mm per 1 m is allowed.

For pool plaster use special waterproof compounds: in addition to sand and cement, they contain hydrophobic polymer additives, plasticizers and other substances that increase their level of resistance to moisture and frost resistance. The plaster can be carried out on a grid or on glue. The first method is used most often.

The procedure for performing plaster pool on the grid:

- cleaning the bowl of debris, dust, or traces of the old finish, if the pool was already in operation and is being repaired;

- treatment of walls and bottom with impregnations that increase adhesion to the plaster composition and additionally protect the material from moisture;

- mesh fasteners, which allows the plaster composition to hold on tight and not crack under the influence of water. It is best to use a fiberglass mesh that is not afraid of moisture and is not susceptible to corrosion, but it costs a lot. A more affordable option is a regular metal mesh, but if water leaks through the plaster layer (and this can happen), the mesh will begin to rust, lose its reinforcing properties, and after 2-3 years the plaster will crack, and the finish will deform with it . The metal mesh should be covered with a special anticorrosive composition. Mesh fasteners are performed on screws size 3.5 * 32 mm or plastic dowels 6 * 40 mm;

- the plaster mixture for pools is sold dry, it is prepared on the site immediately before application according to the manufacturer's instructions, and in the amount that is used for application for 40 minutes. To improve the waterproof properties of the solution, some experts advise adding hydrophobizing additives to it;

- apply the finished plaster with a metal spatula, carefully monitor that the surface is smooth and the mesh does not protrude anywhere;

- when the plaster sets, it is rubbed with a wooden trowel, so that the layer is well compacted and leveled.

You can proceed to the next stage of work after about 14 days - this is the time required for the plaster to acquire the necessary mechanical strength. Typically, the grid method is used when it is intended to finish the bowl with tiles.

Glue method for applying plaster suggests that the cleaned bowl of the pool is treated with impregnations based on acrylic resins and polyurethane, as a result of which the adhesion of the walls and bottom to the plaster mortar increases significantly. The composition of the plaster should be an adhesive polymer.

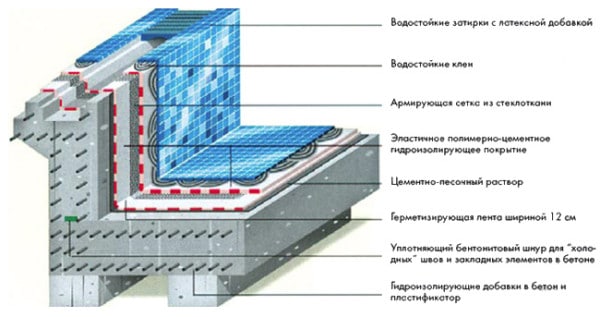

No. 3. Pool waterproofing

Concrete and brick are dense materials, but due to the presence of pores, they absorb moisture, which destroys these materials. The walls and bottom of the bowl must be coated with a material that does not pass water and does not dissolve in it. Outdoor processing necessary so that groundwater does not destroy the concrete base, and it is performed, as a rule, with the help of roofing material. A much more serious influence on the bowl will be exercised from within, therefore, maximum attention is paid to internal processing.

For waterproofing a pool, the following materials are usually used:

- penetrating primer It contains polymer resins that fill well all pores and cracks. The result is a moisture resistant surface. Such waterproofing is easy to do on your own. Some experts recommend applying this composition also under a layer of plaster;

- based formulations rubber and polyurethane resins allow you to get a thin strong film with a high level of adhesion, but such compositions are not cheap;

- polymer cement compositions they are applied as plaster or putty in 1-2 layers, and such a coating achieves water-repellent properties due to the presence of special additives;

- bituminous mastic It has a low cost compared to other materials, good adhesion, forms a solid solid coating, withstands high pressure and is flexible. Before applying the material is heated to 50-600C, so that it becomes liquid, after hardening an elastic coating is formed;

- Pvc film It is strong and flexible, has an attractive appearance, therefore it is used as the final finish. An additional advantage is the low price. However, the film is not very resistant to deformation, it requires careful gluing of the joints.

Note! Before you begin processing waterproofing materials, you must carefully clean the surface of the bowl. If this is not done, then the mastic or film does not fit well and lies unevenly, which ultimately leads to leakage and destruction.

Number 4. Pool bowl finishes

After the surface of the bowl is completely leveled, the most pleasant stage begins, during which the pool can be given the desired appearance. The range of materials for finishing the pool is quite wide, they all meet the basic requirements for this kind of decoration:

- resistance to moisture, the ability to maintain their original properties with prolonged contact with water;

- hygiene, resistance to mold and fungi;

- simplicity in leaving;

- resistance to chemicals used to service the pool.

Among the suitable materials are ceramic tiles, mosaic and PVC film. Less commonly used are natural stone, liquid rubber, painting and sprayed polypropylene.

No. 5. Ceramic tile for pool decoration

This is the most popular solution. However ordinary ceramic tile, which is intended for finishing walls and floors in an apartment, is not suitable for a pool due to high moisture absorption, insufficient strength and the ability to accumulate dirt in the pores.

To finish the pool, use such tiles:

- special ceramic tiles, which differs from the usual composition and production process. It is burned at higher temperatures, as a result of which it is possible to achieve minimal moisture absorption;

- porcelain tile It is made on the basis of white clay and feldspar, firing occurs at high temperatures, due to which the particles sinter among themselves, filling all the voids.It is shockproof and frost resistant material with minimal moisture absorption.

Other types of tiles absorb moisture, therefore, under the influence of low temperatures, they gradually collapse, since ice forms in the structure. In addition, they are an excellent medium for the propagation of microorganisms and the growth of algae, which negatively affects the design of the pool and the water in it.

The popularity of tiles is provided by its advantages:

- frost resistance;

- durability;

- strength;

- hygiene and chemical resistance;

- tiles are available in various shades, so that the pool can be finished as you wish. Most often, tiles are used in blue and blue shades, there are products with a pattern, thanks to which you can recreate the whole underwater world in the pool bowl.

For finishing steps use tile from anti-slip coating, and for a bowl - with a glazed coating, as it looks great when exposed to the rays of the sun. It is not recommended to take a large tile for the pool: the larger the fragment, the higher the likelihood of its deformation under the influence of a mass of water. The maximum for the pool is 15 * 15 cm, and then if the pool has the correct shape. In the presence of bends, a finer tile is taken.

Tile is not only a decor. Together with glue and grouting it forms an additional waterproofing layer, and for the pool to last as long as possible, it is necessary to adhere styling technologies:

- installation begins with the bottom surface, from the end of the end steps. An even line is drawn in the middle of the bottom, tiles are laid from it to the corners of the bowl;

- moisture resistant on a small part of the surface elastic glue with high adhesion. This composition allows you to minimize stress between the base of the pool and the tiles arising under the influence of water. When applying glue, use a notched trowel, the size of the teeth of which depends on the size of the tile;

- the process of decorating the pool bowl with tiles is significantly different from working with any other design or room. The reason is that water has a higher density compared to air. It is important to consider the deformation of materials under its influence. In order not to destroy the finish, it is necessary to make wider seams;

- the first tile is mounted on one side to the center line, on one side to the end, pressed, aligned in level. The second tile is placed on the other side of the center line. Between the tiles leave the same seams with the help of crosses. Tiles near the walls of the bowl may need to be cut;

- when the whole bottom is tiled and the glue is frozen, grout is spread and the joints are filled. Grout should be moisture resistant;

- it is better to cover the bottom of the pool with thick cardboard, so that during the installation of tiles on the walls it is not damaged;

- The first wall tile is mounted near the bottom of the bowl in the far corner of the pool. After the first vertical row is mounted, check its evenness, and continue laying;

- once every several years, repeated sealing of the joints.

Cons of technology: high price and duration of work. It is impossible to lay out a pool of complex shape with tiles - you have to use a mosaic.

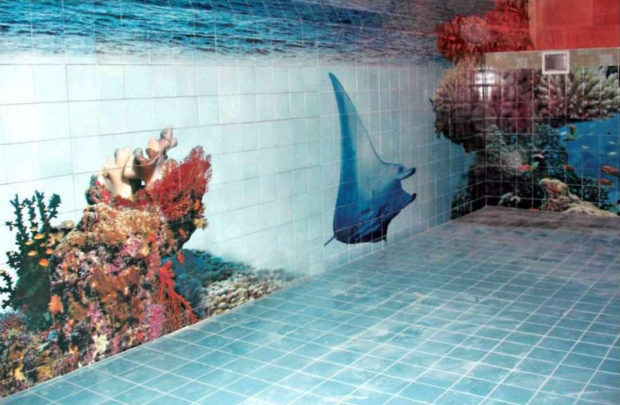

No. 6. Mosaic for finishing the pool

An alternative to tiling is mosaic. It has smaller dimensions, so it is suitable for creating more complex designs and patterns. With tiles, this is not possible, since it is suitable for covering straight sections. Using mosaics, you can lay out any image or pattern directly on the walls and bottom of the pool. Suitable for decoration porcelain and glass parts, both options practically do not absorb moisture and do not collapse under the influence of low temperatures. A significant drawback of the mosaic is only the high price.

Mosaic Laying Principle similar to tile. If you need to lay out some kind of drawing or pattern, installation starts from the center.When facing, you can install vertical beacons using nails and a plumb line. Then, a mooring cord made of kapron fishing line is mounted in the upper part. This is suitable for horizontal cladding so that the joints remain straight. During work, the cord moves up.

To facilitate the work of the master, manufacturers began to produce whole panels of mosaic elements. Tiles are attached to a sheet of paper, which is very easy to remove after installation. A mesh-based mosaic is also produced. Such elements retain high flexibility and can be mounted on curved surfaces.

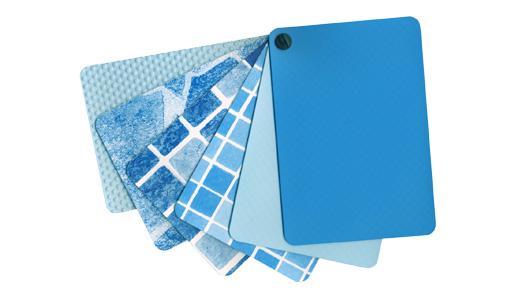

Number 7. PVC film for pool decoration

Pvc filmIt’s a liner or an alcorplane, consists of 4 layers, including reinforced, the thickness is small - only 1.5 mm. The surface can be smooth or corrugated, the choice of flowers is small, but there is. Usually use a monophonic film of blue or blue shades. Looks good with imitation mosaic tiles.

Benefits:

- low price;

- high speed finishing;

- resistance to sunshine;

- simplicity in leaving;

- ability to withstand decent loads;

- resistance to mold and fungi.

The main minus - low durability. If in indoor pools coverage lasts up to 20 years, then in open pools - only about 7 years. In addition, the film can not be used in pools with a complex configuration, it is afraid of sharp objects and chlorine.

The process of mounting PVC film boils down to the following sequence of actions:

- the surface of the bowl should be well sanded. In places with irregularities, the film may wear out faster;

- put a layer under the film geotextile, which will protect it from the appearance of condensation and will avoid punctures;

- a fixing strip is mounted around the perimeter of the pool;

- the film is cut into fragments, which are overlapped and welded under the influence of hot air, you can use a building hair dryer with a special nozzle. Seams can be additionally treated with liquid plastic;

- the edges of the film are welded to the mounting strip;

- film is welded in the corners of the pool;

- gluing the film to the bowl is unnecessary - it will press itself against it and take the necessary shape under the weight of water. Filling with water is carried out gradually.

The film can be used to repair an already functioning pool, and it can be laid directly on top of the tile.

Number 8. Natural stone pool decoration

For the decoration of pools of all natural stones taken use granite and marble. It turns out very beautifully, truly unique and luxurious, but quite expensive and not very practical.

Benefits:

- high esthetics;

- shades of marble and granite are diverse, so finding a material that matches your idea will not be difficult;

- durability, strength, wear resistance;

- resistance to mold, ultraviolet rays, temperature difference;

- the possibility of processing and obtaining any form.

Minuses:

- when wet, the surface becomes slippery and the pool bottom turns into a skating rink. To avoid injuries, it is necessary to use shoes with a non-slip surface, but it often does not save from falls;

- marble in contact with chlorine loses its attractiveness and becomes brittle, and in places with the highest load it is wiped;

- high weight;

- high price.

Significant disadvantages made the stone cladding not very popular - the stone is used to decorate the site near the pool. Difficulties may arise during the installation process - skills will be required, although the installation principle is similar to that described for ceramic tiles.

No. 9. Other pool finishes

Ceramic tiles, mosaics and films are leaders in the field of pool decoration, but sometimes other materials are also used:

- polypropylene. The coating is made of elements with a thickness of 6-15 mm, which are welded by an extruder. It leaves a solid, even coating, resistant to chemicals and loads.In such pools, it is easiest to mount elements for organizing hydromassage, countercurrent. The material does not slip, but does not differ in a wide selection of colors;

- painting. It is rarely used, as the layer will have to be updated every season;

- spraying with rubber. It turns out a seamless surface, but its performance is inferior to other finishing methods.

So that the pool looks great not only in the sun, but also in the evening, you can provide for backlight, and you can illuminate not only the area near the pool. This is about led strip in special boxes that are not afraid of water and can be used to illuminate the pool bowl. Installation of such products is extremely simple, the color of the glow can be anything.

We hope that our information was useful to you. And now, without a second thought, you will take up the construction of the pool to create a great place to relax the whole family.