9 tips for building a house from polystyrene concrete: pros, cons, choice

Recently, the demand for lightweight concrete blocks has increased significantly, catching up and even surpassing the demand for more traditional building materials - brick. There is also competition within the cellular concrete group, and leadership is still holding aerated concrete. Following him foam concretebut in popularity polystyrene concrete is about to overtake it. About half a century ago, he demonstrated this building material quite well: at a low price, it is durable and provides excellent thermal insulation. Cottage with an area of 120 m2 when using polystyrene blocks, you can build in just 2.5-3 months. These advantages are worth considering in more detail the properties of the material and understand whether to build a house from polystyrene concrete, and what features of the material you will encounter.

No. 1. What does polystyrene concrete consist of?

Polystyrene concrete arose as an attempt to make such building material that would not require additional insulation of the walls outside. Polystyrene balls began to be added to the concrete mortar, which provided the material with outstanding heat-insulating properties. The composition of the modern polystyrene concrete block includes cement, sand, water, polystyrene foam granules, special plasticizing and air-entraining additives and sometimes surfactants, which increase the adhesion of concrete mortar and foam balls.

Depending on the proportions in which the components were taken for the block, the material can be used for the construction of load-bearing walls, partitions or as insulation. One block of polystyrene foam replaces 20 bricks, respectively, the speed of construction of the building increases significantly.

No. 2. Pros and cons of polystyrene concrete

Features of the production technology and composition of the blocks allow us to talk about numerous material advantages:

- excellent heat-insulating qualities. According to manufacturers, a wall 20 cm thick will be enough to provide the required resistance to heat transfer in regions with a mild climate. In regions with more severe winters, a wall 30 cm thick is needed, but the most common option in this case is 20 cm polystyrene concrete and foam insulation. The coefficient of thermal conductivity of the material depends on the density, but in any case it is many times lower than that of many analogues;

- excellent soundproof qualities. A wall 20 cm thick is capable of retaining 72 dB of sound;

- The small weight of the blocks and its large dimensions make it possible to greatly simplify and speed up the construction of the house. The need for sophisticated heavy equipment disappears. Moreover, the blocks simply give the necessary shape, so in fact of them you can build a house even with complex architectural elements, however, the consumption of material will increase greatly;

- high resistance to moisture, resistance to mold and rodents;

- high frost resistance. The material can withstand up to 100 freezing / thawing cycles, which is three times more than the same foam concrete;

- the material belongs to the flammability class G1, i.e. It is practically non-combustible. Experiments confirm: after an hour-long exposure to a wall of polystyrene concrete, a temperature of 10000With it does not collapse. True, there is another side to the coin. If the building suffers a fire, it will stand with high probability, but will become unsuitable for further operation, as the walls will lose sufficient strength;

- lack of shrinkage;

- low load on foundation;

- acceptable strength;

- the ability to create a monolithic house from polystyrene concrete, without cold bridges;

- low price.

The main disadvantages:

- low vapor permeability of the material will not allow excess moisture to pass through it from the room, therefore it is necessary to equip a good ventilation system, otherwise the problem of increased humidity and stuffiness inside the house is provided;

- device complexity fasteners. Ordinary nails and screws they will stick very poorly to the wall made of polystyrene concrete, they can literally be pulled out with bare hands, so you will have to stock up with special anchor bolts designed for this material. On the one hand, such a fastening element is pulled together with a nut and washer, on the other hand, the outer sleeve is opened in the form of a petal;

- the quality of the unit is highly dependent on the accuracy of compliance with production technology. If the ratio was violated concrete and granules of foam, then the strength of the block will be small, and with insufficient adhesion, the granules can even begin to fall out of the block. When buying, always be interested in a quality certificate;

- with prolonged exposure to high temperatures, the foam balls burn out, leaving virtually one concrete frame. Its strength and thermal insulation are not high and do not allow using it as an external wall. However, wall cladding with non-combustible materials and high-quality plaster they allow good protection of the walls from fire, and the very ability of the walls to withstand exposure to high temperatures is worth a lot, therefore this drawback cannot be called significant;

- low material density complicates installation windows and doors. If you do not take into account the numerous features of the installation, then after a couple of years you can come across shattered mounts;

- walls must be plastered. The layer of plaster inside is at least 20 mm, outside is at least 15 mm, and the adhesion is stucco not quite perfect.

The properties of polystyrene concrete allow us to consider it as a material for the construction of load-bearing walls of a house. It can also be used for erection fences, sheds, garages and as a heat insulator.

No. 3. Monolithic houses made of polystyrene concrete

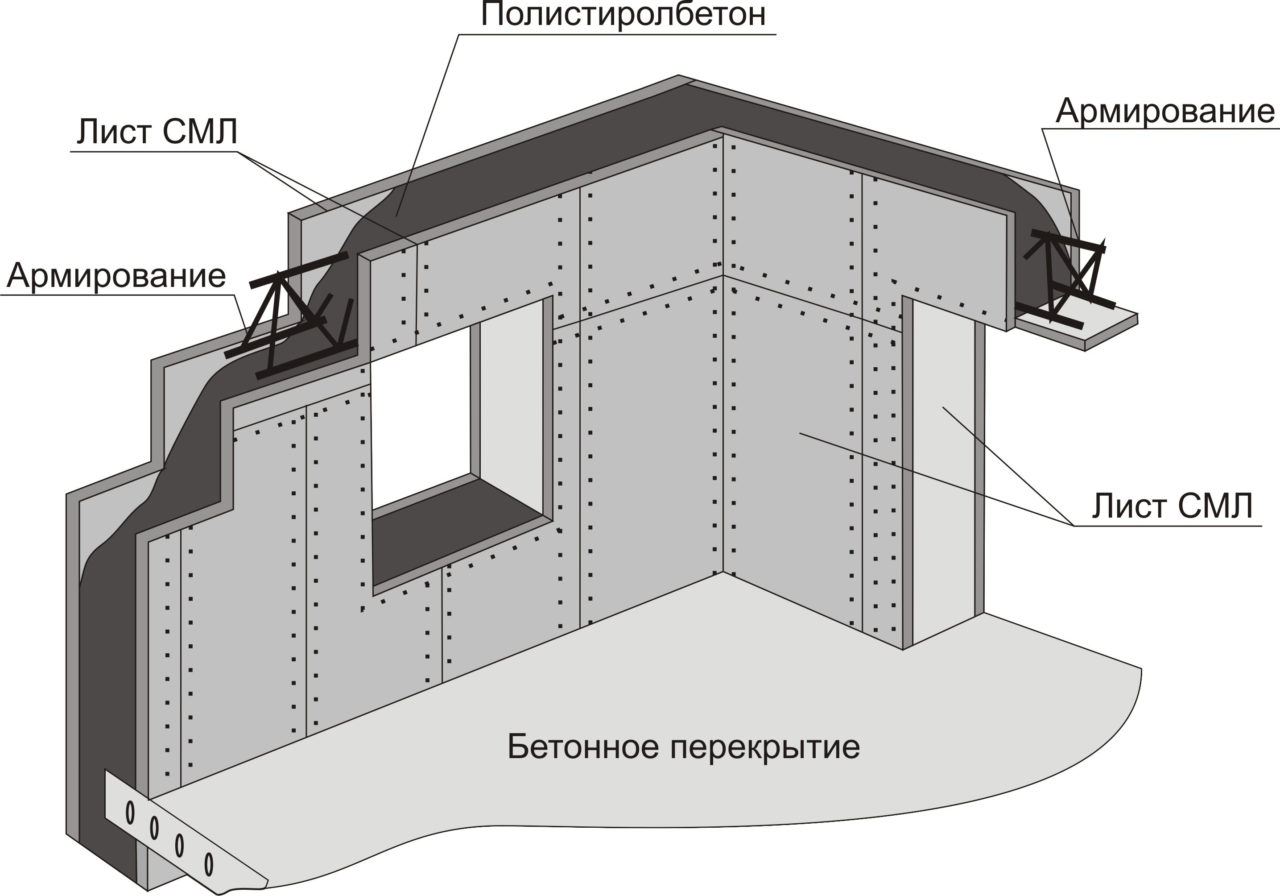

Polystyrene concrete, like expanded clay concrete, allows you to build houses using monolithic technology. The composition of the material is the same, only separate blocks are not made from it - it is poured into the finished formwork, forming the walls of the house.

Advantages of this solution:

- the absence of cold bridges, because there are no seams between the blocks;

- high speed of building a house;

- minimal chance of shrinkage. Blocks of polystyrene concrete are not capable of shrinkage - it can occur due to the use of a solution;

- high strength and durability;

- uniform distribution of load on the foundation;

- the ability to integrate some communications into a monolithic wall.

The main disadvantage is the complexity of the construction. Since the walls need to be poured in one approach, you will need a large amount of mortar and special equipment, so you can’t do it on your own, but from the blocks you can build a house yourself.

Number 4. Density, strength and frost resistance of polystyrene concrete

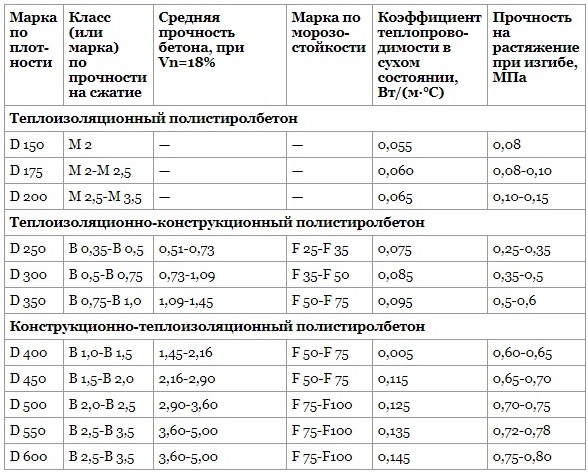

GOST R 51263-99 normalizes the main performance indicators of polystyrene concrete. According to him are determined density grades from D150 to D600where the number means density in kg / m3. The lower the density, the higher the thermal insulation properties of the material and the lower its strength.

Also defined by the standard compressive strength classes from B0.5 to B2.5: the higher the coefficient, the greater the load the unit can withstand. Also, compressive strength is sometimes indicated by the letter M with a coefficient from 2 to 5. Such marking is introduced for a material that is designed without taking into account the requirements of ST SEV 1406, its strength is lower.

Frost resistance it is determined by the freezing and thawing cycles that the unit can withstand, while maintaining the basic performance. For polystyrene concrete, frost resistance ranges from F25 to F100 and increases with increasing density of the material.

By density and a number of indicators depending on it polystyrene concrete is divided into three classes:

- heat-insulating polystyrene concrete density D150-D200 with low strength and low coefficient of thermal conductivity (0,055-0,065 W / m * K). Use for warming of heat-conducting systems, external walls and ceilings;

- heat-insulating and structural polystyrene concrete D250-D350 can be used for thermal insulation of curtain walls and self-supporting walls. In some cases, D350 blocks can even be used for the construction of external load-bearing walls, provided that the building is low-rise and the external cladding is light;

- structural and heat-insulating polystyrene concrete D400-D600 brands are used for the construction of load-bearing walls of low-rise buildings (up to 3 floors) and load-bearing walls of high-rise buildings. Monolithic buildings are also being erected from polystyrene concrete of these brands.

For the basement of the house, blocks with a density of D650-D800 would be suitable, but they are not produced by manufacturers, so this element of the house is better to build from bricks or concrete blocks. It is worth noting that at their own peril and risk, private builders use the D500-D600 unit for arrangement cap 1-, 2-storey buildings and garages, and for the first 10 years of operation there are no problems with these buildings.

No. 5. Types of polystyrene concrete

Polystyrene concrete is produced by manufacturers in the following modifications:

- wall block used for masonry walls and partitions, has dimensions 588 * 300 * 188 mm or 588 * 380 * 300 mm;

- septum block taller and thinner, has dimensions 588 * 600 * 92 mm;

- jumper blocks with reinforcement they are used, as a rule, for masonry at the locations of window and door structures; they have dimensions 380 * 300 * 1300 mm;

- polystyrene concrete solution delivered to the construction site by special transport, necessary for the construction of houses using monolithic technology.

No. 6. What to consider when choosing and buying polystyrene concrete?

Recently, a lot of low-quality product has appeared on the market, which is caused by the growing demand for polystyrene concrete. Some companies that previously produced the foam block now began to produce polystyrene concrete, and often attempts to quickly please the market lead to poor product quality. What you need to pay attention to and what to check when buying?

- uniformity of filling with concrete granules;

- uniformity of granules;

- compliance with the weight of the block of the specified density;

- when ordering polystyrene concrete, it is necessary to find out the maximum information about the manufacturer, so you can and should safely ask where the production facilities are located, be interested in the features of the manufacture. A normal manufacturer can invite you to production and demonstrate products, as well as tell you what wall thickness is best made, what block density to choose, advise how to fix shelves better, which adhesives and mortars are best used when laying - in general, you should answer any question;

- certificate of quality is another important point. But even its presence is not always a 100% guarantee of quality. If you are dealing with a distributor and he shows you a quality certificate of the manufacturer, then it does not interfere with making sure that the manufacturer is cooperating with this seller.

Number 7. Large manufacturers of polystyrene concrete, or whom can you trust?

The choice of the manufacturer can be called the cornerstone in the construction of polystyrene concrete houses. There are many in the country, but among the largest enterprises call the following:

- BlockPlastBeton LLC is a subsidiary of a major manufacturer of building materials LLC GradStroy. It uses modern equipment, production is carried out in compliance with all technologies. Polystyrene concrete blocks up to D500, heat-insulating boards and reinforced lintels are available. Delivery is carried out by truck throughout the European part of Russia;

- LLC Polystyrene Concrete Plant It was founded in 2001 and has proven itself very well over the years. From polystyrene concrete, floor slabs, wall panels, blocks, reinforced lintels and mortar are produced here. All products are certified. The company is located in the Sverdlovsk region, but delivery is carried out throughout Russia;

- LLC “Polystyrene concrete-SPb” offers blocks of polystyrene concrete with a density of D200 to D500 and partitions with a density of D The company has all test reports and relevant certificates;

- LLC "WARM CONCRETE" - A responsible Novosibirsk manufacturer that offers polystyrene concrete in the form of blocks, lintels and mortar for monolithic construction technology. Material with a density of D200-D is produced. Products are widely used by private and large developers;

- LLC "Baushtoff-Polystyrene concrete" - Krasnodar company, which produces blocks and reinforced lintels made of polystyrene concrete, product quality is constantly improving, production is being modernized.

Number 8. Do-it-yourself polystyrene concrete

You can make polystyrene concrete blocks with your own hands. The more carefully you follow the technology, the more durable and durable products will be the result. Component kit for making blocks simple. Will need cement, sifted sand, water and polystyrene granules. Instead of concrete, a gypsum mixture is sometimes taken as the basis. It is also possible to add special modifying substances to the mixture, for example, an air-entraining additive or even tar to increase moisture resistance.

Proportions of components depend on which block is planned to be received and what the emphasis is on, thermal insulation or strength. The larger the portion of cement, the more durable the resulting block. The following proportions are suitable for a structural-thermal insulation block: 1 bucket of cement, 3 buckets of sand, 6-8 buckets of polystyrene in granules, slightly less than 1 bucket of water. The sequence is as follows:

- pour water into a concrete mixer or stationary mixer, fill all additives and half of all granules, so that cement sticks to walls less. Water can then be added to achieve the required consistency;

- cement is added, the mixture is stirred until smooth;

- sand and polystyrene residue are added, everything is well mixed, the required consistency of the solution is dry, it will be easier to work with forms;

- mold casting. In their quality, you can use a metal box, which is independently welded from sheets of metal with a thickness of 3 mm. You can use the matrix form from old boards, but it is important to lubricate the form with machine oil. Above, the solution is well rammed, you can turn on vibration for 2-3 seconds, but no more - prolonged vibration violates the integrity of the blocks;

- blocks are removed from the metal form, and from the wooden ones, too, but you can leave them for a day inside the form. The products are left to dry for 24 hours in a warm place, the temperature is above +150C, you can cover them with plastic wrap. After 4 weeks, the blocks gain the necessary strength for construction.

No. 9. Features of building a house from polystyrene concrete

Building a house is a complex multi-stage process that requires at least basic specialized knowledge. In general terms, building a house from polystyrene concrete looks like this:

- arrangement of the foundation. Since the total weight of the structure is small, you can use a columnar, unfilled strip or pile foundation. For complex types of soils, it is better to choose a screw pile;

- walling according to the selected technology: from blocks, with removable or non-removable formwork. Building out of blocks begins with waterproofing and determining the highest place from which the laying of walls begins. When laying, verticality and horizontalness are clearly observed with the help of fishing line and level. To increase horizontal strength, reinforcing mesh can be laid. If blocks with solid voids are used, vertical reinforcement is performed. The thickness of the seam of the solution is not more than 8 mm, it is better to use special glue. Monolithic walls erected using a removable formwork of plywood with a thickness of 15 mm, it is protected by a film of polyethylene from moisture. Plywood is supported by the use of metal profiles; they are attached to the foundation with self-tapping screws or dowels. Plywood sheets are attached to the profiles, first create external partitions, then internal ones. The mortar is well rammed during pouring; the formwork can be dismantled in a few days. Instead of plywood, you can use brick walls - this fixed formwork, while the facade cladding is not needed;

- ceiling slab made from special polystyrene concrete panels or also by pouring method. Floor screed performs in standard ways;

- exterior finish house made of polystyrene concrete is necessary. You can use decorative brick, siding, plaster. Inside, you also need first a layer of plaster, then - putty, and then - as you want: wallpaper, painting, decorative plaster.

A house made of polystyrene concrete can be built in a matter of months, and it will stand under all the features of the technology for decades. Importantly, do not forget about high-quality ventilation and specific fasteners.