8 ways (methods) of immersing piles in the ground

Even the most remote person from the topic of construction understands that the basis of any building is foundation, and realizes that the durability and strength of the building depend on its reliability and correct execution. When it comes to the construction of large houses and critical facilities, usually choose pile foundation. It can be used on any type of soil, it provides maximum reliability to the building, and it takes less time to install such a foundation than to erect a tape or any other type of foundation. For the pile foundation, different types of piles and different methods of immersion are used. The choice depends on the type of soil, the location next to other objects, the nature of the structure, the length of the piles and the mass of other factors. We will figure out what methods of immersion of piles in the soil exist, and when it is better to apply one or another method.

First, a few words about types of piles. They are stuffed and hammered. The first are obtained by installing the reinforcing cage in a pre-prepared well and subsequent filling concrete. Driven piles they are delivered to the installation site already ready, for their transportation directly to the dive point, crane installations are used. When talking about immersion, they mean precisely driven piles.

Piles are immersed in the soil by various methods:

- shock;

- vibrating;

- indentation;

- screwing up.

The combination of some of these methods allows us to talk about several mixed methods of diving piles:

- vibration shock;

- vibration indentation;

- submersible diving;

- immersion using electric osmosis.

We will deal with the main subtleties of each method.

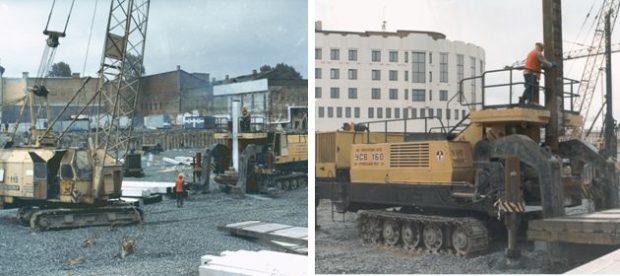

No. 1. Impact dive pile

The shock method involves the transfer of piles of translational energy, due to which it plunges into the soil, displacing part of it out or compacting it. For this, complex and heavy mechanisms are used - shock self-propelled or rail units. For their movement on the construction site, a flat surface is necessary, therefore, the territory must first be leveled. The pile is held in an upright position thanks to the copra, a kind of arrow.

In the early stages, diving is slow so that you can control the correct angle. It affects the pile itself rod or tubular hammer. With the same weight, the tubular hammer has a 2-3 times higher impact force than the rod. So that piling equipment does not destroy the pile, a special headgear is used. Diving continues until the pile reaches the design depth.

To the main advantages method include:

- possibility of work on any type of soil;

- high speed and productivity of installation work;

- increasing the bearing properties of the foundation, since piles, plunging into the ground, compact it in the zone by 2-3 diameters around them;

- work can be carried out in almost any weather.

No. 2. Pile dipping vibratory method

Thanks to the vibration that is transmitted to the pile by special equipment, significantly friction and soil resistance are reduced. That is why for diving piles to the design depth often require much less effort than when driving. We must not forget that when vibrating in the same way as with the shock method, soil compaction about 1.5-3 piles diameter (it all depends on the type of soil), so we can talk about the appearance of additional load-bearing abilities.

This method involves the use of vibration shakers. Such installations through the headgear transmit mechanical vibrations of a certain frequency to the pile. Due to this effect, the soil becomes floating, and the pile begins to sink under the influence of its own weight. If we are talking about long heavy piles, then use low frequencies, for light small piles, higher frequencies are more suitable (more than 1,500 vibrations per minute).

The process of immersion begins with the installation of the vibrator in its original position, fastening the pile and aligning it vertically. Before starting work, it is recommended to perform a test run to make sure that there are no deviations from the vertical. Such equipment is expensive, and it should be managed by qualified specialists: the price of a vibro-loader, or rather the cost of its use, will be lower if you use the rental services. In Moscow and throughout Russia, drilling rigs are offered by the Drilling Technologies Group of Companies: the cost includes the services of an experienced operator.

The vibratory method of piling is recommended for use in the following cases:

- sand and water saturation soils. Sheath piles, metal sheet piles and reinforced concrete piles in this case are immersed at a speed of 3.5-7 m / min;

- on wet and dense soils, the method is also applicable, but for this it is necessary to pre-drill the well;

- when immersed in clay and heavy loamy soils 15-30 cm before reaching the design depth, it is better to switch to the shock method.

Note that in a dense urban area, vibration should only be used in non-resonant modes. It is desirable that the oscillation frequency was not higher than 40-50 Hz.

No. 3. Vibro-shock method

As the name suggests, this method assumes combination of vibration and shock loading. The pile is simultaneously affected by vibrations and shocks, which allows it to quickly and relatively easily enter the soil. This method is used on dense soils, where another method will be ineffective.

The installation, which implements vibro-shock immersion, has two frames: on one there is an electric generator percussion apparatus, on the second - an arrow with a vibration absorber. The vibrator is connected to the pile with the help of a headgear, then the pile is positioned and the mechanism starts. In a similar way you can immerse piles up to 6 m long.

Number 4. Pile Vibration

This method combines the shock, vibration method and indentation method. Three forces act on the pile at once. The installation used for the work consists of an electric generator (powered by a tractor or excavator engine), a double-drum winch, a guiding boom with a vibration absorber, and blocks through which the pressure cable from the winch approaches the vibration absorber.

In the designated place, the vibro-loader lifts the pile and sets it to the point where the dive will take place. The pile is protected by a headgear. When the unit is turned on, the pile begins to dive under the influence of vibration, its own weight, the mass of the vibrator, the mass of the tractor or other equipment, and shock load. Conveniently, installation does not need to prepare travel routes. The method is suitable for working with piles up to 6 m long.

No. 5. Indentation of piles

The indentation method is used on particularly hard and dense soils (with the exception of rock) for diving piles of continuous and tubular section of small length (3-5 m). The method is based on the effect of a static load on a pile.During the work, special equipment is used, which takes up enough space, therefore, the implementation of the method is possible only in areas where at least 500 m are available2 area.

First, the pile in a vertical position is placed in the guide arrow of the installation, and the pile shaft is fixed with clamps. The pile is deepened by a meter, after which a headband is lowered onto its head, which will transmit pressure to the pile through the block system from the base machine (excavator, tractor). This pressure causes the pile to gradually sink into the ground. If the pile cannot reach the required depth, with the help of equipment it is slightly raised, lowered again and continued indentation.

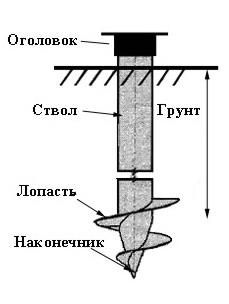

No. 6. Screwdriving piles

Method used to screw piles. They consist of two parts: a steel tip with blades adjacent to it (ensures easy entry into the ground) and the pile shaft itself made of steel or reinforced concrete. Screwing is used in the construction of bridges, power transmission lines and other facilities with a large load. Optimally suitable for use on loose or flooded soils, can be used in any climate. Screw piles can even be screwed in areas with dense buildings.

Screwing takes place thanks to special equipment that is installed on the frame of the truck. On the installation drive, the pile is mounted in an inventory shell (not using a headband). Thanks to the transmission, the torque from the equipment goes to the pile, it begins to rotate and go deep into the ground. If the soil is too dense, then a slight lifting of the pile and a restart of the mechanism are allowed. After the required depth is reached, the pile is unclenched.

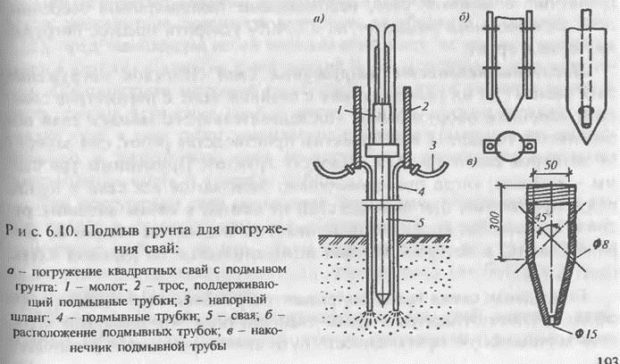

Number 7. Submersible piling

Soil wash method is used on loose and loose soils (sandy and sandy loamy soil) for installation of piles large diameter and length. It is not allowed to use the method on subsiding soils and when there is a threat of subsidence of nearby buildings. The method is based on the wetting of the soil and the subsequent reduction of the friction force, due to which the pile easily enters the soil under the influence of its own mass and the mass of the hammer installed on it.

Tubes are built into the tip or side walls of the pile, through which water is supplied under high pressure (about 0.5 MPa). Under the influence of water, the soil becomes softer, pliable, loose and washed out. This principle is familiar to us from the sandbox. The soil resistance of the pile is reduced, water also erodes the soil layers adjacent to the pile walls, reducing the friction force. The water supply tubes have a diameter of 38-62 mm. Side wash (provided with 2 or 4 tubes on the sides of the pile, 30-40 cm above the tip) more effectively reduces the friction force of the pile walls compared to the central wash (provided with a single or multi-jet tip in the center of the pile).

It is clear that in this case we are not talking about high bearing capacity, therefore, often the washing method is combined with the shock method. In this case, costs are reduced and the reliability of the foundation being built is increased.

Number 8. Electroosmosis method for piling

The electroosmosis method cannot be considered independent - it is rather a way to simplify the process of pile sinking. Good for dense and water-saturated clay soils and loams. The essence of the method is to connect two piles into an electrical network. An already submerged pile plays the role of the anode, and not yet clogged - the cathode. When the current is turned on, the soil near the anode loses moisture - it passes into the zone near the cathode. In wetter soil, as you know, to pile pile is much easier. Immersion is carried out by shock or indentation.

After the current disappears in the network, the properties of the soil will be restored in a short time, so you should not worry about the bearing capacity of such a foundation.

Buranable pile dipping method

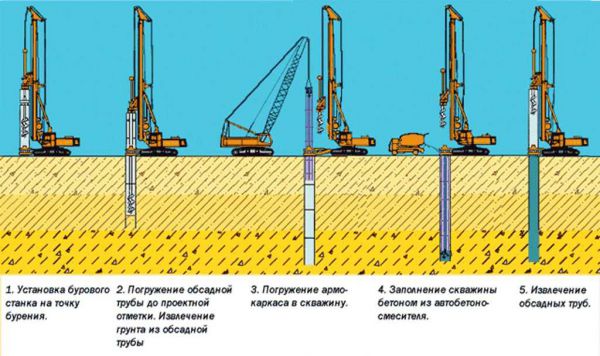

Let us make a reservation right away, the buranaibivny method only indirectly relates to methods of immersing piles, because in this case piles are created immediately on the site, but we will also briefly describe it. Piles are created by constructing a frame of reinforcement in a previously prepared well, which is then poured concrete. A well is created using an impact or rotary drill.

Bored piles are created in one of the following ways:

- casing. A pipe is installed in the well that protects the walls from collapse. Then created reinforcement cage and prepared concrete is poured. The pipe itself may remain in the well or be dismantled. Naturally, in these two cases different pipes are needed;

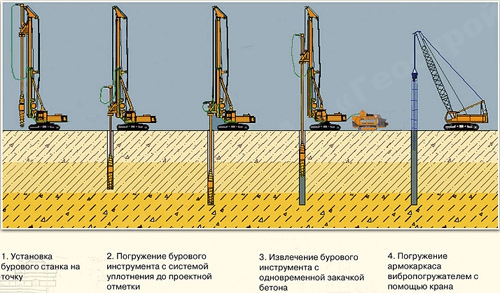

- without casing. Concrete mortar begins to pour into the well during its drilling. It strengthens the walls and plays the role of a casing. Next, the reinforcement cage is placed in concrete. For a more even distribution of concrete use a special pipe for pouring, with a vibrator at the end.

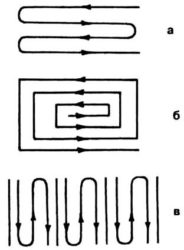

Finally, we note that scheme Diving and the subsequent arrangement of piles is also of great importance:

ordinary scheme assumes evenly remote arrangement of piles relative to each other. Suitable for sandy and gravel soils, not used on dense soils, easy to implement;

ordinary scheme assumes evenly remote arrangement of piles relative to each other. Suitable for sandy and gravel soils, not used on dense soils, easy to implement;- spiral circuit involves the location of piles from the center of the foundation to its perimeter in a spiral. In this case, we can talk about the most uniform distribution of the load and reduce the likelihood of shrinkage;

- sectional diagram involves the installation of two supports in one row, the subsequent skipping of one row and the installation of two supports again. So the whole pile field is passed, after which piles are installed in the missed rows. The option is suitable for areas with dense soil.

The construction of the foundation is a very responsible process, which must be approached with an understanding of the features of the soil, the specifics of the building being built and a number of calculations. The immersion method, together with other factors, affects the reliability of the foundation, so its choice must be taken seriously.

ordinary scheme assumes evenly remote arrangement of piles relative to each other. Suitable for sandy and gravel soils, not used on dense soils, easy to implement;

ordinary scheme assumes evenly remote arrangement of piles relative to each other. Suitable for sandy and gravel soils, not used on dense soils, easy to implement;