5 tips for choosing piles for private construction

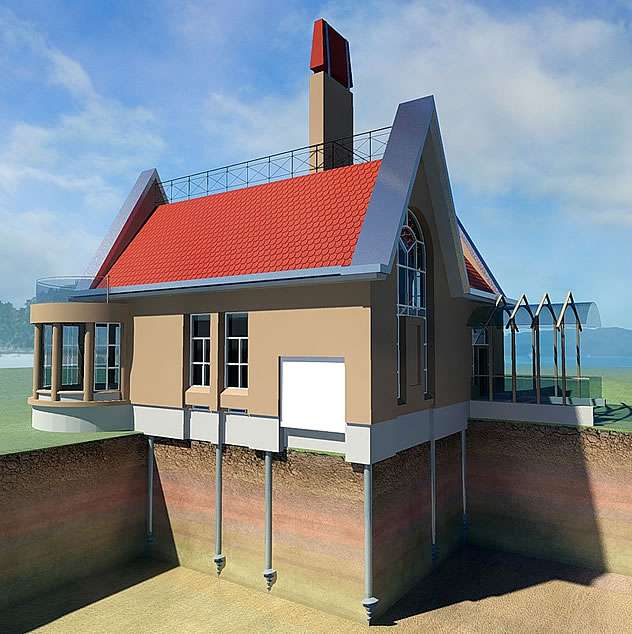

The construction of a cottage, a private house or a summer residence is not complete without the construction of a foundation. This is the foundation of the basics. From the right one type of foundation and the quality of its performance depends on the durability of the constructed structure. In private construction, different types of foundations are used, but more and more often the choice falls on the pile foundation. It can be used on any type of soil, regardless of the groundwater level, it allows you to carry out all work as soon as possible, but special equipment is needed to equip it. In addition, it is necessary to determine the type of piles, because depending on the material, installation method and other features, their properties are very different. We learn to choose piles for private construction and deal with their key features.

No. 1. Types of piles according to the material of manufacture

All piles that are used in private construction, according to the material of manufacture can be divided into the following types:

- wooden;

- metal;

- reinforced concrete.

Wooden piles

Wooden piles are great for private construction. They are standing cheaper than metal and reinforced concrete, and cope with small loads no worse. Today, wooden piles are used in the construction of cottages, temporary structures and small bridges.

The raw materials for production are larch, cedar, oak, pine or fir wood. Use a healthy straight-fledged winter felling forest. Piles can be whole and spliced. Whole ones have a length of 4.5-16 m, spliced - up to 25 m. When splicing occurs, the individual segments are connected end-to-end using overlays. However, for private construction, the length of whole piles will be enough. Splicing technology is sometimes used to increase diameter. batch splicing.

The lower end of the wooden pile gets a point, the length of which is about 1.5-2 diameters. If the dive will be carried out in hard ground with many obstacles, then the tip is protected by a shoe. The upper part is also protected by a headgear, because the installation of the pile is carried out by clogging, indentation or vibration.

Metal piles

Metal piles can withstand more severe loads than wooden ones, but they also cost more. On such a foundation they build large brick cottagesas well as lighter frame housesat home from timber. Metal piles are suitable for strengthening the emergency foundation, as well as when creating extensions to an existing building.

These products are made from seamless steel pipes, but steel dowels, I-beams and other rolling profiles can be used. The diameter is from 25 cm to 100 cm or more; box-shaped bases are also available. As a rule, metal piles receive a pointed tip, but it may not be. If the weight of the building is large, then you can strengthen the foundation by filling hollow metal piles with concrete, but in private construction this is rarely used.

Separately, it is worth highlighting screw piles, they have blades at the end, due to which they have enhanced strength properties.Screw piles are immersed by screwing. With their help, they make the foundation for extensions, since there is no dynamic load on the ground. Often, screw piles are used to strengthen emergency foundations: they are installed along the contour of such a base and are attached to it using special brackets. Normal manufacturers cover anti-corrosion coating, but even under it you can consider the quality of the welded joints. Welding should be performed by a continuous seam, using wire technology. Quality anticorrosion coating can be appreciated by trying to scratch it a bit with a key or a coin: normally, this will not be so simple.

Screw piles may have a welded or cast tip. Cast, of course, is better, but in private construction it will also fit welded - the loads here are small.

Reinforced concrete piles

Reinforced concrete piles in private construction are used less often - they are designed for more severe loads and are indispensable in multi-story and industrial construction. However on weak and mobile soils and in conditions of a sharp change in soil moisture, such piles will be the best option for the construction of cottages.

Reinforced concrete piles are available in two variations:

- monolithic;

- national teams.

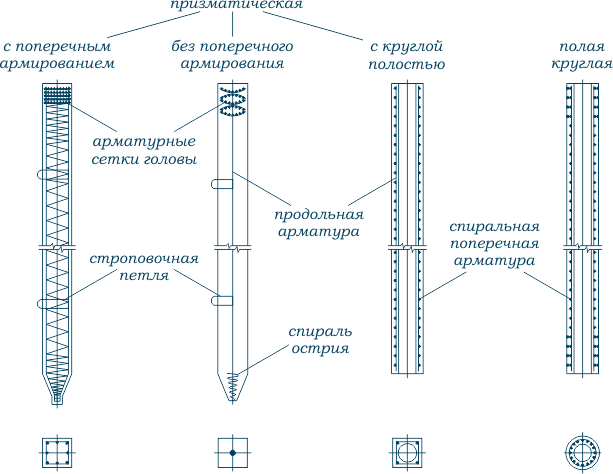

Monolithic piles have a square or rectangular section, the side is from 20 to 40 cm. They receive longitudinal reinforcement of tensile or non-tensile fittings, transverse reinforcement is performed using a low-carbon wire with a cross section of 5 mm or more. Monolithic piles are also produced with a cavity inside a cylindrical shape, but the wall thickness in them should not be less than 4 mm. When immersed in soil, monolithic piles are protected by a steel shoe. The upper part, which takes on the shock load, is closed by a headband in the form of several nets.

Prefabricated Piles assembled from several sections, the length can be anything. As a rule, assembly is carried out in advance, but particularly long piles can be assembled at the installation site.

Reinforced concrete piles are mounted by the method of driving, which is what their main disadvantage. Not only is it noisy, so in areas with dense buildings, changes in soil masses can occur. Another minus is the difficulties in terms of transportation, because Reinforced concrete piles large, heavy and quite easily damaged. They must be transported in horizontal rows with the same orientation of the ends. Between the rows it is better to lay wooden gaskets, and round piles are transported together with special bars that will not allow them to slide.

Nonetheless, merits the reinforced concrete piles are many. With their help, you can create a solid and reliable foundation. Moreover, when they are driven in, soil compaction occurs in the area of immersion, which positively affects strength.

They also make reinforcement and concrete stuffed piles, they are only created directly at the construction site by pouring concrete into drilled wells.

No. 2. Types of piles according to installation technology

Driven piles

These are, as a rule, reinforced concrete piles with a pointed end. Installation takes place thanks to the use of special drum kits. Piles are protected from destructive loads thanks to the headgear.

To the main the benefits universality applies to such piles: you can use the method on any ground and in any weather. Speed and productivity are high, and the soil around the pile is slightly compacted, which increases the bearing capacity of the future foundation. Among cons - the inability to use near other buildings, since the effects of the shock wave can be devastating.

Vibro-submersible piles

It is possible to make a pile sink into the ground if it is exposed to vibration. Vibration is transmitted to the ground, reducing its friction and drag. The soil becomes floating, and the pile sinks under the influence of its own weight.With a similar effect, the soil around the pile also compacts, so we can talk about the natural strengthening of the foundation. This method is used when dealing with sandy and water-saturated soils. It is more difficult when working with low-moisture and dense soils, and for rock formations the vibration method is not at all suitable.

Among the benefits vibro-submersible piles less noise and relatively low cost of arrangement. Of course, you cannot do without special equipment, but you can rent it. Residents of Moscow and the region can contact the IntelStroy company, which rents vibration dampers, and together with qualified personnel.

Screw piles

The screwing method is used for metal and reinforced concrete piles with a steel tip. Screw piles are distinguished by the presence of blades at one end, due to which they enter the soil. Installation can be carried out manually, but it is easier to use special equipment.

Screw piles are used on loose and flooded soils, as well as when it is necessary to equip the foundation in a zone with dense development, so when building a house in the city is a great option.

Pressed piles

In private construction, such piles are used extremely rarely. A large static load acts on the pile, and the equipment that creates it requires a sufficient amount of free space. This method is used when working with hard and dense soils.

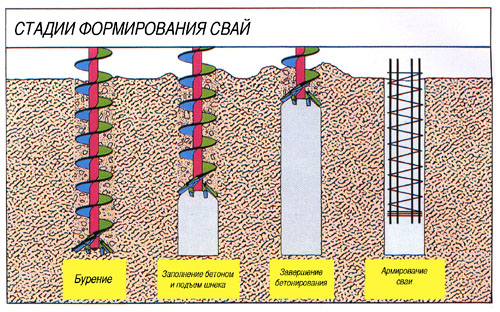

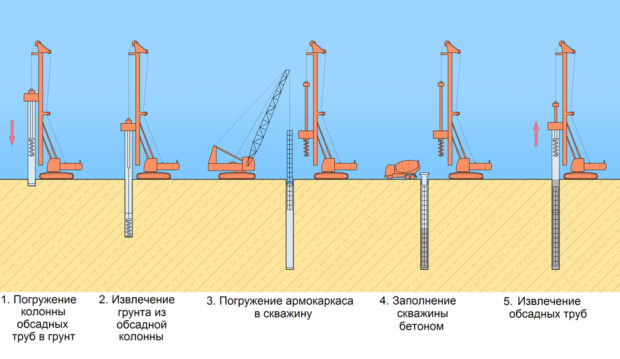

Bored piles

This is a separate type of pile. They are are created directly at the site of the foundation. The creation process consists of the following steps:

- well preparation using a percussion or rotary drill;

- installing casing or pouring concrete, depending on which method is used. If the option with casing is chosen, then first a special pipe is immersed in the well, which will strengthen the walls. Otherwise, during the drilling of the well, the solution is poured concrete, which has the same function - to strengthen the walls;

- submersion fittings;

- concrete pouring. In some cases, casing is then taken out, but pipes that are not dismantled are often used.

The advantage of the method is relative simplicity and low cost, therefore, in private construction this method is very popular. It will not be necessary to transport long piles, but it will be necessary to prepare a high quality of concrete, and here without a concrete mixer there is nowhere. Experts say that the unpleasant feature of this method is the inability to control the quality of manufactured piles. As for the limitations, on soils prone to expansion and horizontal movement, such a foundation cannot be used.

No. 3. Types of piles by type of soil impact

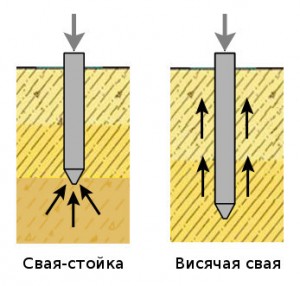

According to the type of impact on the soil or the nature of the work, piles are divided into two types:

- supporting, or piles. When immersed in the ground, they rely on stable soil. Suitable for areas where dense, stable soil is located under unstable soil at shallow depths;

- hanging piles. The load on the soil is transmitted through the force of friction on the side walls of the soil. Such piles are installed in places with a high level of groundwater.

Number 4. Types of piles according to section shape

According to the cross-sectional shape of the piles are:

- square and rectangular. Often these are produced reinforced concrete piles. This is the most popular option in most construction industries. Such piles are recommended for use when construction is on soft soils, they are used in the reconstruction and strengthening of the existing foundation;

- round piles, or shell piles differ in the open lower part, therefore, during installation they are filled with soil, which increases their bearing capacity. Such piles have found application in seismically active areas;

- hollow square and round piles. These produce metal piles, as well as some reinforced concrete.The latter are used in the construction of low-rise facilities.

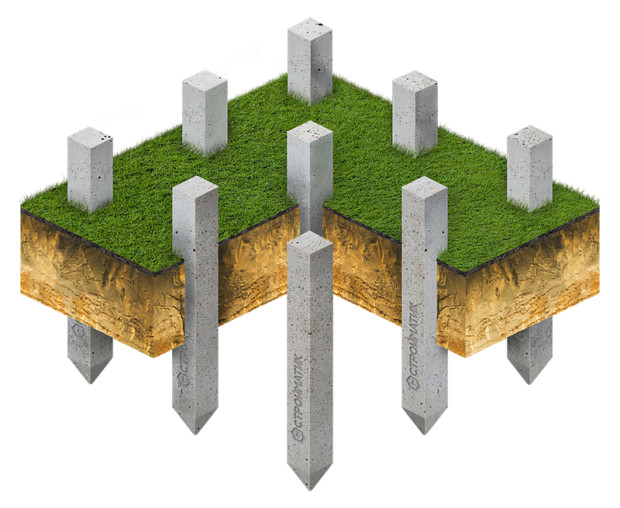

No. 5. Calculation of the number of pile supports

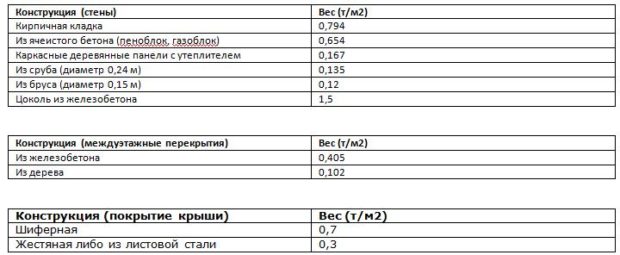

The choice of the type of piles, their number and places of immersion is best entrusted by a professional, since this is a very crucial stage. However, he himself does not interfere with knowing the basic principles of calculation. It takes place in two stages. First you need to determine the total weight of the building, and then calculate the bearing capacity of a particular pile in a particular soil.

The total load of the building on the foundation calculated as the sum of the following parameters:

- actual mass of the building. The weight of the floors, walls and roof is summed. The calculation can be performed using tabular values of the mass of the main building materials;

- snow loads. It all depends on the region where the house is located. For the southern regions of the country, this figure averages 50 kg / m2, for the central ones - 100 kg / m2, for the north - 190 kg / m2;

- payloads. This includes the weight of the furniture that will be used and the people living. In order not to bother yourself by counting the mass of all pieces of furniture, you can use the average value - 150 kg / m2.

The data obtained are summarized and multiplied by a safety factor of 1.2.

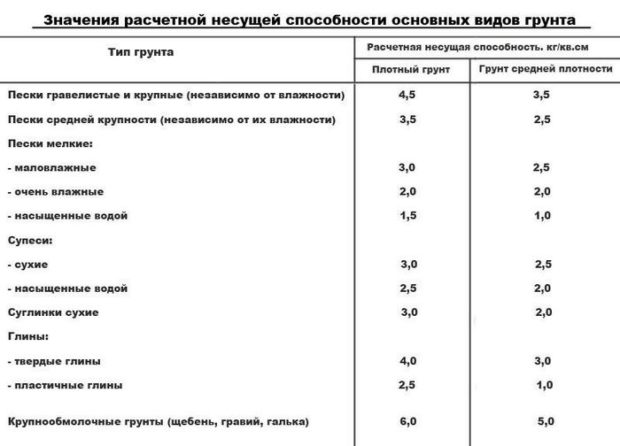

The bearing characteristics of piles depend on the type of soil. Ideally, it is necessary to conduct geodetic surveys in order to know exactly the bearing capacity of the soil, but if this is not possible, you can use the tabular data - just know the type of soil. For example, the carrying capacity of dry clay of medium density is 2.5 kg / cm2and dense coarse sand - about 6 kg / cm2.

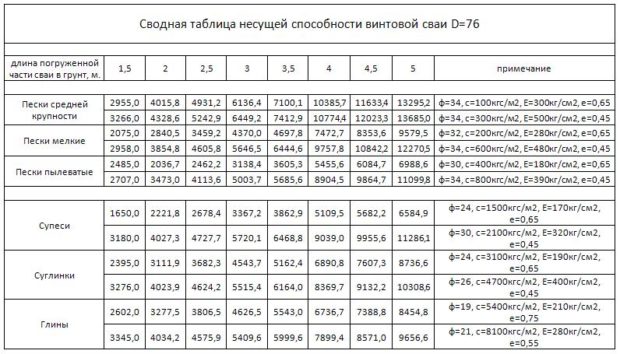

Each type of pile has its own bearing capacity.

For example, we need to build a 2-storey house of timber with dimensions of 10 * 8, we will use screw piles 89 * 300 mm. If the house is located in the central strip, then the snow load will be 10 * 8 * 100 = 8 t / m2. The payload of each of the floors 10 * 8 * 150 = 12 t / m2, i.e. for the whole house 24 t / m2. The mass of the house itself is approximately 44 tons. The total load (44 + 24 + 8) * 1.2 = 91.2 tons. Suppose the soil is soft plastic clay, the piles will be submerged 2.5 m (their bearing capacity is 5 tons ), then we need 91.2 / 5 = 18.24, i.e. 19 piles.

Piling Depth choose based on the type of soil. Piles with a length of 2.5 m are usually sufficient for stable dense soil. If the soil is unstable in the area, the length of the pile should be such as to reach a more dense layer of soil.

Often in private construction, screw piles are used. They are produced in different ways. diameter:

- 57 mm - such piles are suitable for creating the foundation for light fences;

- 76 mm - piles for the construction of heavier fences (for example, from corrugated board), as well as light buildings (arbor);

- 89 mm - piles for construction country housessmall private houses outbuildings. Such a support withstands 3-5 tons on average;

- 108 mm - an excellent option for the construction of private houses of any type, withstand from 5 to 7 tons.

The distance between piles is calculated for each individual project. It is not recommended to make the distance between the supports more than 3 m for frame houses, and more than 2 m for buildings from foam block and gas block. If there are strong winds in the region, the distance between the supports should be no more than 2.5 m.

We emphasize once again that when it comes to such a serious matter as the foundation, it is better to make the most accurate calculations, and not to save on building materials and equipment.