6 Tips for Choosing a Garage Rack

What is a typical domestic garage? This is not only the room where the car is located, but also the place where you can store a lot of things necessary for car maintenance, repair and hobbies. If tools, tires, cans of liquids, boxes and other supplies that many motorists have in their arsenal are randomly scattered around the garage, then there will be less space in it and it will be more difficult to find the necessary item. A rack can organize a storage system - a rather primitive, but very important construction for a garage. If previously only storage racks were on sale, and for the garage the masters assembled them on their own, today everything has changed. There are a lot of ready-made structures - it remains only to determine the criteria for choosing a rack in the garage.

What should be a garage rack?

To reasonably talk about the selection criteria, for a start it would be nice to understand what requirements a garage rack should meet. It is fair to speak of the following characteristics:

- matching garage size. The main task of the rack is to help the car owner organize the storage system correctly. If things are scattered around the garage, then they will take up a lot of space, interfere with parking and servicing the car. On the other hand, the rack also should not restrict freedom of movement, so you have to solve a difficult task - to find a rack that would accommodate everything you need, but at the same time take up a minimum of space. If there are few things, then the task is simplified, but you can find a solution in any case. Fortunately, there are a lot of different design options;Suggestion on the topic

The company Region Voronezh LLC manufactures and sells garage racks of various sizes, models are designed for different loads, there are special racks for hardware and tires.

The company Region Voronezh LLC manufactures and sells garage racks of various sizes, models are designed for different loads, there are special racks for hardware and tires. - stability and reliability. First you need to imagine what you will store on the shelves of the rack. It’s one thing if it’s small fasteners and a small power tool, another thing is if it’s tires, filled large cans and other heavy equipment. In the first case, a design that can withstand up to 60 kg of load is suitable, in the second - 120-170 kg or more. Higher strength will affect the price, and that is why it is so important to determine in advance the contents of the shelves;

- security. It is desirable that the rack be resistant to fire, as the garage is a place of increased danger. If you intend to store liquids, then the shelves should not be slippery, and even better - they should have a side. The design should not have sharp elements so that you do not accidentally get injured. Metal parts should be fine protected against corrosion, since getting liquid on them is not uncommon;

- convenience. The size and number of shelves, their location must fully meet the requirements of the owner of the garage, and without a preliminary analysis of the contents of the rack it is difficult to say which model will be most convenient.

Making an intermediate conclusion, we note that it is very important when choosing a rack in a garage to understand what size the structure will suit you, and where exactly it will stand. In order not to get confused and not make a mistake, make a plan on which the dimensions of the garage, the place for the car and the area intended for the garage will be indicated.Let you spend a little time, but significantly reduce the likelihood of error.

Types of garage racks

There is an opinion that the best, most reliable and proven rack for a garage is stationary. But besides him, there are other options, and they have their advantages. In some cases, the stationary model may even be inferior to competitors. So, weigh your requirements for the rack and choose the most suitable type:

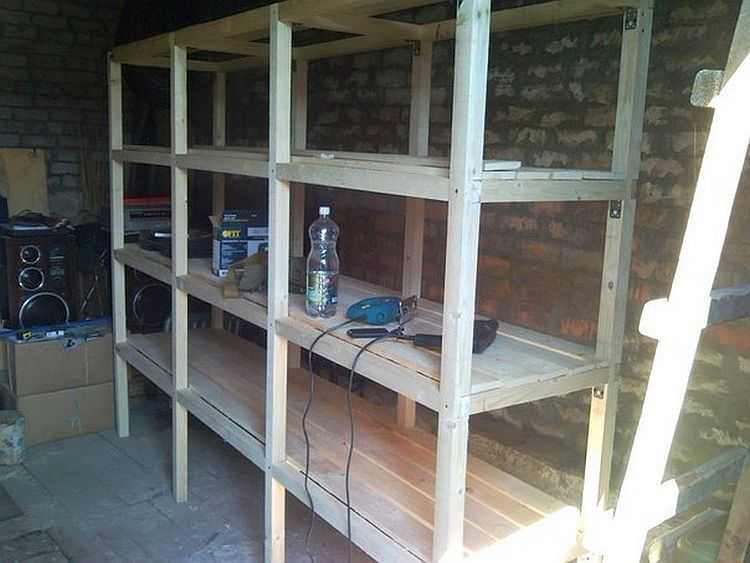

- stationary rack attached to the floor, walls or ceiling, therefore it is considered the most reliable and durable. It consists of vertical racks, horizontal partitions and shelves. Shelves can be metal or wooden. If provided by the design, the shelves can be rearranged, changing the volume of the storage sections. If necessary, some shelves can be removed altogether, creating a place to store tires. For those who are going to store something quite heavy, this type of shelving is best suited. Typically, models are made of metal, but shelves in some cases can be wooden;

- prefabricated / collapsible - It is, rather, whatnots than full-fledged shelving. It is convenient that the master can dismantle such a rack at any time, transport it and assemble it again, but such structures cannot be called durable. However, if you are going to store only hand tool and small fasteners, then such a rack will be enough for you. As a rule, products are made of metal;

- mobile shelving differ in mobility. If during work in the garage the rack will interfere, it can be quickly moved to the far corner, and then put back. During car repair, the structure can be moved closer so as not to run after the right tool. It would seem an ideal option, if not for its lack of stability. Mobility is provided by the presence of wheels or rollers. It is their presence that does not allow the design to be so reliable as to withstand decent loads. It’s impossible to say that mobile shelving is bad, because in some cases their capabilities will be quite enough;

- island rack can be considered a special case of a mobile structure. They are designed for 2-3 shelves, have a small height, are equipped with wheels, although they can be without them. They withstand a small load, convenient for storing small things. The island rack on wheels helps a lot when repairing a car;

- rotating shelving - A rarity in our garages, but they are great for placing hand and electric tools, hardware. The rotation function provides the easiest accessibility to everything that is stored on the shelves of the rack. If in the garage you often do repairs, then you will like this kind of design. It is not necessary to replace it with a stationary rack - it can become an additional element in the organization of the storage system. There are models designed for floor and desktop installation. They take up little space.

Separately, it is worth highlighting modular shelving, which are slightly different from the generally accepted concept of “shelving”. Like modular furniture, a modular shelving unit consists of several blocks. As blocks, not only traditional shelves mounted on vertical racks can be used, but also hinged shelves and drawers of various types, as well as systems such as rails, designed to hang inventory. Any storage system can be assembled from various blocks and, if necessary, it is easy to supplement it. Such systems, however, are more suitable for storing light objects.

Also worth mentioning hanging shelves. They will not be able to fully replace the rack, but they will be able to supplement it. By placing several of these shelves under the ceiling, you can organize a storage place for items that are rarely used. Hanging shelves can be equipped with drawers for storing trifles, they can be angled - there are a lot of options.The main thing is not to overload this storage place, since all the load goes to the wall.

Along with wall shelves are used and ceiling. They can also be regular or angular, can have several tiers, equipped with drawers for storing items. This is an ideal way to use the free space under the ceiling.

Material of execution of a garage rack

Let's start again with a stereotype that assures us that the best shelving is a metal shelving. And to argue with this statement is difficult. Indeed, if you need to store something heavy, then metal is an ideal option. But if the garage is nothing heavier than a pump or drillthen alternative solutions can be found.

So, for the manufacture of shelving the following materials are used:

- metal. The frame is assembled from a corner and a profile pipe, the shelves are made of sheet metal. As a rule, steel is used, which is coated with a layer of powder paint that prevents corrosion, since dampness, i.e. high humidity - in garages are not uncommon. A more serious option is galvanized steel. Metal racks are as durable as possible, so that you can safely store on shelves tires and a heavy tool. The advantages also include high durability and resistance to fire. The downside is susceptibility to corrosion, but manufacturers are struggling with this issue by applying protective coatings. If you make a rack with your own hands, then the issue of protection against rust will fall on you - good, there are enough special tools on sale. Another minus of the metal shelving is the price, but such an investment is more than paid for with durability and reliability;

- tree. Previously, when ready-made shelves were not sold, the craftsmen had to make them with their own hands, and often a tree was used as a fairly affordable and easy to process material. Today, wood is still actively used in the manufacture of shelving. To create a frame, a beam of 50 * 50 mm is used, and for shelves - boards, plywood, OSB or particleboard. The main plus is the low cost, in addition, a wooden rack is easy to assemble with your own hands. The design is lightweight, because suspended mounting is possible with any wall material. A heavy metal shelf, by the way, is attached to aerated concrete walls Not recommended. The disadvantages of the tree, alas, are many. This is not such a high strength as metal, fire hazard, exposure to moisture, temperature extremes and microorganisms. To extend the life of the structure, you will have to regularly process wood special substances. Experienced car owners recommend first impregnating the wood with a means of increasing resistance to moisture, and then covering it with a layer of paint;

- plastic it is used extremely rarely and the reason is clear - inability to withstand more or less high loads. Today there are racks for hardware on sale, their frame is metal, and the boxes are plastic. Boxes are divided into compartments, so they can store dozens of types of various fasteners. A convenient option for the workshop, but in an ordinary garage there are unlikely to be so many different hardware to fill even a small rack.

Separately, it is worth noting the combined racks in which the frame is made of metal and the shelves are made of wood. If you are not going to store anything very heavy, then this is a great option. Some craftsmen who decided to make a rack with their own hands and are not averse to saving money, some of the shelves are made of metal, and some - wooden. So that such a trick does not go sideways, you need to imagine in advance what will be stored and where.

Permissible load

Tires, a motor, wrenches - all these are rather heavy things, and the shelves under them should not bend and break. Therefore, again, think over what you will store and study the characteristics of the rack when you purchase it. Among others, there will be a load that a shelf and a rack section can withstand.

The most “tender” racks can withstand up to 60 kg per shelf and 350 kg per section. For more or less serious loads, it is better to take models that withstand up to 120 kg per shelf and up to 500 kg per section. Stronger models withstand 170 kg per shelf and 750 kg n rack. There are also the most durable models that can withstand a load of 300-900 kg per shelf. There is a need for such structures, perhaps, in auto repair shops, when it is necessary to store several sets of wheels, among which there may be trucks.

Garage Rack Dimensions

Typically, racks are placed along one of the walls - this solution allows the most efficient use of the garage space. Make several measurements in advance to know which limit in height, length and width to count on. Keep in mind that many manufacturers sell shelving in vertical sections from 70 cm to 1 m or more in length, so it will not be difficult to assemble a structure of the required size.

Here are some guidelines to consider when selecting shelving sizes:

- height. It is better to take as high a rack as the ceilings in the garage allow. Thus, it will be possible to place a maximum of things on the same area. Shelves for sale are 1.5 m, 1.8 m, 1.9 m, 2 m high, less often you can find other sizes;

- shelf depth. Here the balance is important. On the one hand, the shelf should be roomy. On the other hand, too wide shelves take up a lot of space, and if you store all sorts of little things on them, then access to objects in the background will be complicated. The depth varies from 30 to 80 cm, the step is 10 cm. The optimal depth is 50-60 cm, but, first of all, you need to take into account what exactly you are going to store. It is clear that for large objects it is better to choose the shelves deeper;

- section length. The gold standard is 1 m. With a standard frame, a shelf of this width will be strong enough. To assemble a rack with a length of 4 m, for example, it is possible from 4 sections of 1 m. If for some reason it is necessary that the length of the section is more than 1 m, you will have to fork out for a reinforced structure with channel or a thick bar. It will cost more, and if you do it yourself, the manufacturing process will be more complicated;

- distance between shelves can be almost anything. It is convenient when the position of the shelf can be adjusted to adapt the rack to store certain items. It is recommended that the first shelf be located at a height of 30-50 cm from the floor. This will ensure proper safety for you and allow easy cleaning.

If desired, sections of different heights can be combined; the width of the shelves in them may also vary. In general, only you know which rack will fit perfectly into your garage and meet all the requirements.

Secrets of organizing space

The experience of numerous garage owners suggests how to place everything on the shelves of the rack so that everything fits and nothing falls. Here are some tips you might want to listen to:

- it is best to put the rack under the long wall of the garage;

- The most commonly used items are stored on shelves, which are easier to get to. Everything that is necessary from time to time can be placed higher;

- it is better not to place containers under the ceiling that can be knocked over when you try to get them off the top shelf. In general, canisters with flammable liquids are best stored on the lower shelves away from electrical wiring;

- in the presence of a large number of tools, you can select a separate wooden shelf for it, in which to make the required number of holes. They insert screwdrivers, and as a result, the search process is noticeably simplified;

- Perforated panels are perfect for placing keys, hooks are attached to them, for which the keys hold perfectly. Such a panel can be made part of the rack or taken outside;

- for a hand-held electric tool, drawers can be provided, or stored in shelves of a workbench, if any;

- To simplify the cleaning process, some prefer to use shelves made of metal mesh. Dust does not linger on them, it easily falls to the floor, from where it is much easier to remove;

- tires are stored on the lower shelves, and the shelves themselves are removed, leaving only horizontal horizontal bars. Up to 5 tires for passenger cars are placed on a shelf 40 cm deep and 1 m long.

When buying a finished rack, find out how long the manufacturer has been working on the market, whether users are satisfied with its products, what materials it uses, how it protects against the negative effects of moisture, and what guarantees it gives. If there is time and opportunity, you can try to build a rack with your own hands, the following videos will come to your aid.