5 tips for making a staircase from a corner and channel

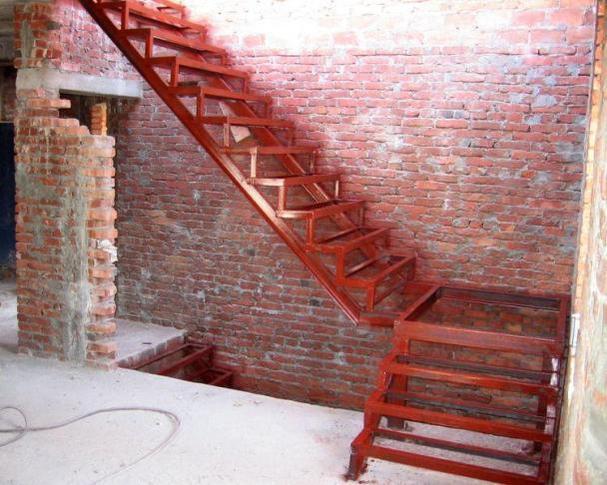

If you are lucky to have a house or apartment with two floors, then the question staircase constructions you definitely have to worry. Spiral, marching and on rails, straight and rotary - stairs can be different, but no matter what shape you choose, we all want the structure to be solid and reliable. From this point of view, stairs on a metal frame show themselves in the best way. A profile pipe and sheet metal can be used, but a structure created on the basis of a channel and a corner will be more durable. Is it worth undertaking to make a staircase from a corner and a channel yourself or is it better to entrust this work to professionals? What is important to consider when calculating? What are the stages of the process of creating a metal frame of a staircase? We deal with all these issues.

No. 1. What are the good stairs on the channel and corner?

The structure of the channel and corner is used to create a closed frame, which will eventually be sheathed with cladding materials. A properly executed metal frame has the following advantages:

- high strength subject to a quality weld. The channel can withstand significantly higher loads than a profile pipe, but it also costs, of course, more;

- by combining a corner and a channel, you can build a ladder of any complexity;

- wide possibilities of design. The metal frame can be sheathed with wood, chipboards, drywall, metal or polymeric materials. The entire metal base is completely hidden under the decorative lining;

- metal is not afraid of temperature changes, sunlight, with proper processing - it is resistant to corrosion, therefore both internal and external stairs are created from it;

- the staircase from the corner and the channel does not creak or vibrate when walking.

If the design is done by yourself without the use of forging and other expensive elements, then the cost of such a ladder will be acceptable.

The degree of complexity depends on the size and configuration of the stairs, and, of course, on the level of preparation of the performer. To create a frame, they usually take a channel from No. 8 to No. 12, and sometimes even higher - it all depends on the loads that will be assigned to the frame, so without calculation there is nowhere.

No. 2. Do it yourself or hire professionals?

Assessing your strength, you must be extremely objective. If you have sufficient experience with welding machine, the desire to deal with the principles of calculating the stairs, as well as a sufficient amount of time and a faithful assistant, you can try to make the stairs out of a channel and a corner do it yourself. If you have to complete the first frame in your life, then it is better to give preference to the simplest straight staircase, since rotary and screw structures are already the level of professionals.

If there is even the slightest doubt in your skills, it is better to immediately contact specialist. But here, alas, it is not so simple, since there is a high probability of running into specialists of too wide a profile who know far from all the details regarding the construction of stairs on a metal frame. Ordinary welders are often also unable to cope with the task, since they do not know all the nuances of the staircase, and as a result, the strong frame created by them will be difficult or impossible to trim with wood.

It is best to contact a company that specializes in the manufacture of metal frames for stairs. In the Moscow Region, the pioneer in this direction was the “Plant of stairs on a metal frame”, which is engaged in the design, manufacture and installation of stairs from a corner, channel and profile, as well as sheathe them at the request of the customer. A responsible attitude to their work allows you to give a guarantee for a 10-year framework. All welding works take place in the workshop, which saves the customer time. The company carries out stairs of any complexity, and so you can be sure of the quality, you can visit the production and see everything with your own eyes.

Regardless of your decision to make the frame yourself or order it from specialists, you need to know the basic principles of calculation and the stages of work, because it concerns your home.

No. 3. Stair requirements

To begin with, all the stairs you have ever seen are different in type of construction:

- marching stairs - the most simple, popular and comfortable. A continuous row of steps is called a march. For maximum convenience, it is recommended to do no more than 17 steps in one march, and if it is necessary to provide for more of them, then it is better to equip the inter-stairway. Marching stairs can be direct (for self-arrangement - the very thing) and rotary. The latter can save space without loss of comfort. Among the marching stairs kosourah and on a bowstring. Kosoures have a stepped, sawtooth shape, are under the steps. Bowstring - a tilted beam, steps are inserted into the grooves;

- stairs fastened to the wall with bolts or bolts. Outwardly, it seems that the steps soar in the air, but this does not affect the strength of the structure, the main thing is that the wall withstood such a load;

- spiral staircases suggest the presence of a support column around which steps are arranged in a spiral. For convenience, it is inferior to other types of stairs, but it allows you to save a lot of space.

When talking about the production of a metal frame, they usually mean marching stairs. However, the metal frame does not need to be sheathed - it can remain in sight, but then it is better to make it from a profile or even metal sheets (for loft style, eg).

Climbing and descending stairs should be comfortable, therefore:

- optimal stair width - 80-90 cm (exactly at least 70 cm). If more, you will have to strengthen the design so that the steps do not bend;

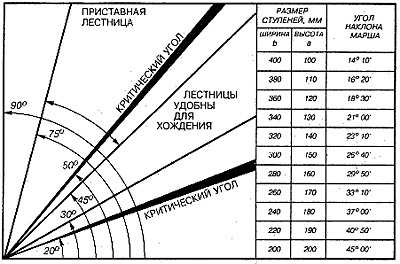

- optimal slope angle - 30-45 degrees, the angle of 50 degrees is called critical, and all that is even more is attics and ladders, they are not intended for constant use;

- optimal step height - 15 cm, but in practice this can be difficult to achieve. Stairs with steps up to 19 cm also come out quite comfortable;

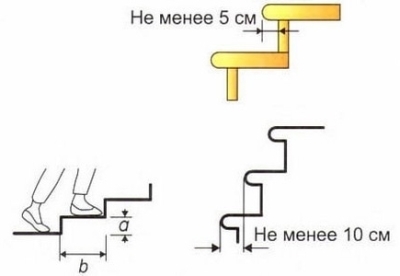

- optimal step width - 30 cm (at least 27 cm for sure), but this is difficult to achieve in a limited area, so they often go to the trick, increasing the area of each step due to the protruding part above the lower step. The length of the protruding part should not be more than 5 cm, and the free space (without overhanging the top element) should be at least 10 cm;

- corner and channels are connected by welding or thread. The first option is most preferable, allows you to get a more solid structure. Emergency and fire escape may be further enhanced.

As practice suggests, An ideal staircase in terms of all parameters can be built only when a lot of space is allocated for it, for example, in the entrance of an apartment building. In all other cases, we have to look for compromise options and experiment.

Number 4. Calculation of the stairs

The main thing is to make all measurements correctly. In this matter, it is better to be even too pedantic and boring, otherwise in the end you can get a completely different frame that you want.Experienced professionals advise recheck measurementsmade by the contractor if you hire him.

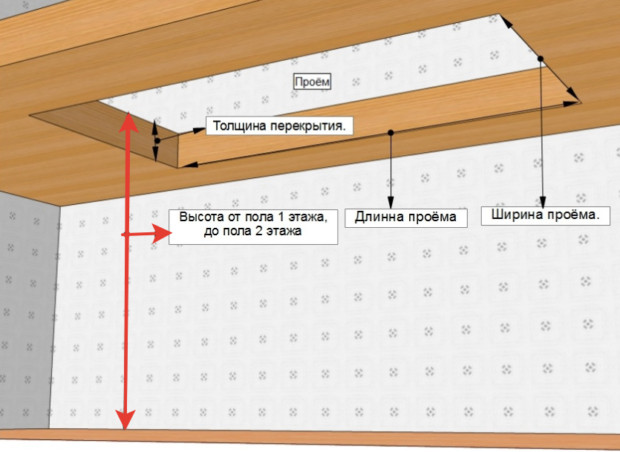

At the first stage, it will be necessary to measure the following parameters:

- future staircase height from the floor of the first floor to the floor of the second floor. Please note - not to the ceiling of the first floor, but to the floor of the second floor. It is also worth considering the need for work on leveling the subfloor and take into account the type of finishing material in order to understand the final floor level;

- opening length from the end of the floor to the extreme wall, it is better to measure the length several times, since due to the curvature of the surfaces in different parts this indicator may differ. In the calculations take the minimum value;

- opening width, from wall to wall, it is also better to double-check the width from different sides.

It is best to make calculations in special programs. By the way, they are used by professionals when designing stairs, but you can also independently calculate a simple single-march straight staircase:

- when all the initial parameters and the angle of the staircase are determined, we calculate the length of the staircase itself. It is not difficult to do this using the Pythagorean theorem. It turns out that the floor of the first floor and the line perpendicular to it, drawn to the supposed end of the stairs on the second floor, are the legs of a right triangle. Let the length of the march be 400 cm and the height 250 cm, then the hypotenuse or the length of the staircase itself will be 472 cm. This is the length of the kosour, which are made of a channel;

- number of steps depends on the height of the riser. The latter ideally is 15 cm, but in fact it can be 16, 17, 18 and even 19 cm. For each parameter, the number of steps is calculated. For this, the height of the stairs must be divided by the height of the riser. With a staircase height of 250 cm, we get: with a riser of 15 cm, the number of steps is 16.7, with 16 cm - 15.6, with 17 cm - 14.7, with 18 cm - 13.8 and with 19 cm - 13.15. If you round, then you can build a staircase with the number of steps from 13 to 17;

- for example, a variant with 14 steps and a riser height of 18 cm is selected, then the depth of each step will be 400 cm / 14 = 28.6 cm, which is an acceptable value;

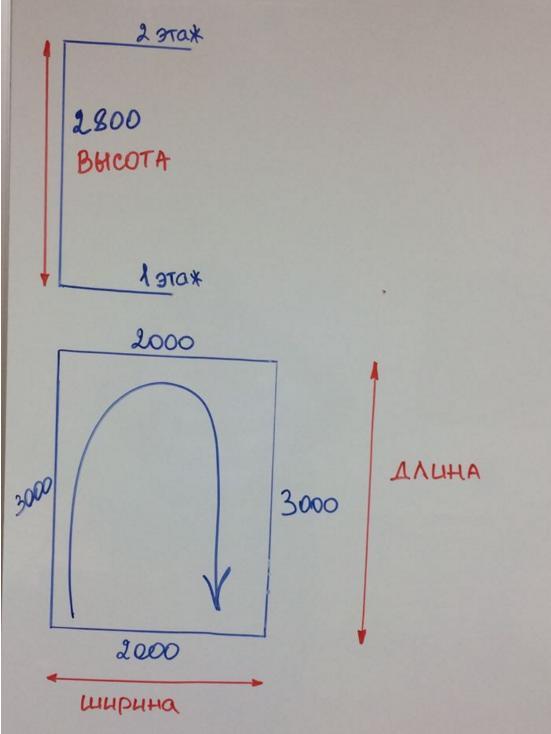

- if the stairs are not straight, then the calculation is a little complicated. Thanks to the use of interfloor platforms and rungs, it is possible to realize the design that is most comfortable for ascents and descents on a small area. If there are no clear requirements in advance how the staircase should be located, then several options can be considered. The easiest option after a straight staircase is a staircase with one interfloor area. Its width will be equal to the width of the opening (let's take 2 m as an example), and 1 m is considered the standard length. If the shaft is 3 m long and 1 m is allocated to the platform, then 2 m remains on the flights of stairs. With a stepping part of 25 cm, the number of steps will be 200 cm / 25 cm = 8 steps in each march, and if you consider the site as a step, the total number of steps will be 17 pieces. Now you should calculate the height of the riser, for which the height between the floors must be divided by the number of steps. At a height of 280 cm, this parameter will be 280/17 = 16.47 cm, rounded to 16.5 cm. Excellent! The error associated with rounding is compensated by the lower steps, which will be slightly different from the rest. The gap between the marches should be at least 10 cm;

- the floor of the second floor can be used as the last step, then the height of each riser will decrease by about 1 cm;

- To make sure that the calculation is correct, you can even draw a profile of the future staircase with a pencil on the wall before starting installation work. If suddenly the location was not taken into account visor or heating radiatorbut at this stage all this will show up. You may have to make the site not clearly in the middle of the stairs, or make other changes. The video very well explained how to calculate the stairs.

We all try to design the perfect staircase, but, alas, this is not always possible. You can double-check your calculations and evaluate how comfortable the design will be using the following formulas, where a is the step part, cm, and b is the riser height, cm:

- a - b = 12-15 cm;

- a + b = 45-46 cm;

- 2b + a = 60-64 cm.

Try to make some staircase designs. with a different number of steps, different risers height and depth of the stepping part, calculate the stairs of different designs, and only then choose the best one from the obtained options. To make all the calculations is not as difficult as it seems.

If you have any difficulties, you can order a design of stairs from specialists. Also on the network there are successful examples of using ready-made projects from the Internet, which can be slightly edited to suit individual requirements. According to the draft, a metal profile is purchased, preferably with a small margin.

No. 5. Installation of the staircase frame from the channel and corner

Initially, it is worth taking care of the availability of everything you need. First of all, this is a welding machine with electrodes, mask, mittens and safety glasses. Also need Bulgarian, drill or hammer drill, primer, paint for metal, as well as little things like tape measure, level and pencil. Beginners in matters of welding are recommended to use inverter-type devices. If there is very little experience, then it does not hinder to practice welding on other elements in advance.

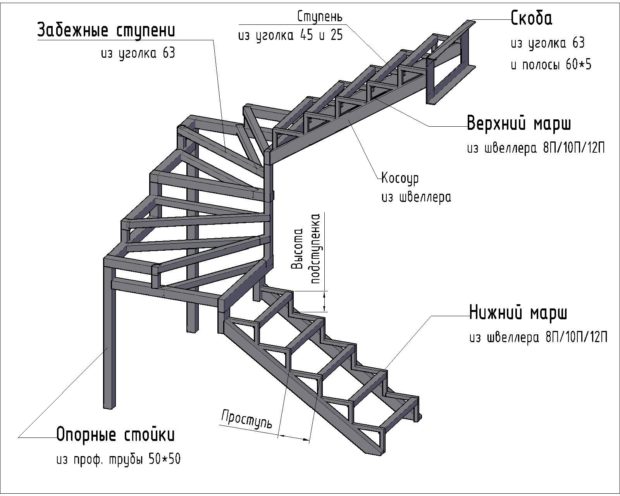

As beams for stairs, usually take channel 8-14, less often use an I-beam. The pipe can also be used, but it is less durable, it is usually used for stairs that will not be sheathed. A corner is used to create steps. - for beams it is not suitable due to its low strength, but there are cases when two corners are welded. To create the supports of the steps take corner size 32 * 32, 35 * 35 or 40 * 40.

The procedure for the manufacture and installation of the frame is as follows:

- clearly identify the place where the staircase will be installed. If one of the bowstrings (or even both) is located near the wall, then this will further strengthen the structure, since it becomes possible to mount to the wall;

- the length of the channels will be equal to the distance from the floor of the lower floor to the floor of the upper floor, taking into account the selected slope. Two blanks are cut with a grinder, then the cut is polished with a file or the same grinder. If the width of the stairs is more than 120 cm, then channel supports are better to make three;

- if it is assumed that there are stairwells, then installation begins with them;

- The bowstrings are attached differently to the floor. You can hammer the pins into the floor, and then weld the channels to them. When organizing the screed, you can take care of the metal mortgages, to which the channels will be welded as a result. If the walls are monolithic, then experts recommend mounting through fittings and the 50th corner. Large self-tapping screws are suitable for wooden floors, and if the walls are made of aerated concrete of low density, it is better to transfer the entire load from the stairs to the floor, arranging the supporting legs;

- the mares will be mounted on channels and support the steps. Mares are made from a corner, its dimensions repeat the dimensions of a step. In fact, a filly is a L-shaped part, where the horizontal part is equal to the width of the step and the vertical part is the height of the approach. The easiest way to make a filly from a whole corner. It is enough to make a cut in the form of a right triangle in the right place on one of the planes, bend the corner to a right angle and weld the seam. You can weld a filly from two separate parts;

- after the channels are installed, proceed to the installation of filly. Better to start from above. The first step will be flush with the second floor or 16-18 cm lower - it all depends on a pre-compiled project. First, the filly is installed and welded to one of the channels, then it is leveled to the level so that everything is strictly horizontally. After that, you can weld it on the other side.Immediately proceed to the installation of the filly opposite, carefully monitoring the level;

- it is easier to establish and fix all subsequent filly, as the end of its horizontal part always rests against the beginning of the vertical part of the previous element;

- after all the fillies are mounted, they move on to the most pleasant thing - the installation of steps, fencing and other decor. To strengthen the structure to the protruding corners, it is necessary to additionally weld the beam from the same corner. If the steps are made of stone or other heavy material, it is better to weld a rectangular frame made of the same corner on the filly;

- As a cladding for steps, you can use wood, particle boards and even glass; for outdoor stairs, a metal sheet with special notches is often used. If you are going to mount wooden steps, then on the filly you need to make two holes for fasteners with a drill. Wood fasten screws;

- the railing is welded to inclined beams or filly. Railings are provided for all stairs with more than three steps;

- when the frame is assembled, all joints are carefully processed, burrs and burrs are removed. Then the whole structure must be primed and painted. special compounds for metal. After that, you can proceed to the facing work.

If you have certain skills in working with metal and a welding machine, then you will be able to build a simple single-march staircase. Assembling a frame for a spiral or rotary staircase is much more difficult - it is better to entrust this work to professionals, and, knowing all the basic stages of designing and creating a frame, you can control the work of specialists and ask clarifying questions.

article class digging 2 weeks but attacked today

THANKS.