Geotextiles for garden paths: 5 tips for choosing and laying

Have you ever wondered why some tracks serve for decades without much damage, while others begin to deform the very next year after laying? If you thought about it, you probably could have suggested that in the second case, serious errors were made at the installation stage. And there is. There can be many mistakes, but one of the most serious is the failure to use geotextiles or the use of inappropriate material. To prevent unpleasant consequences on your site, we will figure out which geotextile to choose for garden paths and how to properly lay it.

Why is geotextile needed when arranging garden paths?

Garden paths - An important decorative part of any site. In addition, serious functions are assigned to it. At a minimum, the path must be strong and durable, not sag in the first rain, not deformed from the roots of the trees, regardless of what material it is made of. Geotextiles come to the rescue - a synthetic material that is made from polymer threads.

Geotextiles differ in the method of production, density and size of the canvas - for different purposes they take the most suitable material. The main thing is that the geotextile be of high quality and can fulfill the functions assigned to it. To be sure of quality, it is better to buy material in a trusted place.

Residents of St. Petersburg and the region can order geotextiles in the Resource company, which is a distributor of large domestic and foreign manufacturers, therefore it can guarantee quality and the most favorable prices. If necessary, specialists will help with the calculations and tell you the most suitable type of geotextile.

Residents of St. Petersburg and the region can order geotextiles in the Resource company, which is a distributor of large domestic and foreign manufacturers, therefore it can guarantee quality and the most favorable prices. If necessary, specialists will help with the calculations and tell you the most suitable type of geotextile.

Geotextiles perform the following functions:

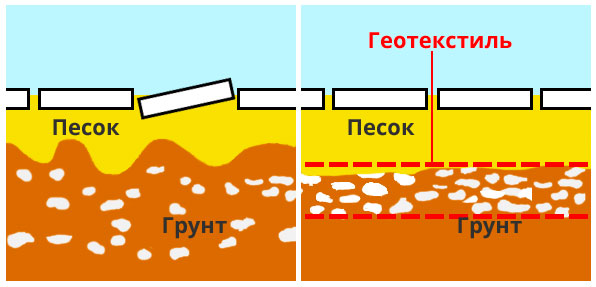

- track deformation protection, formation of internal voids and precipitation under the influence of rain, snow and loads. Without geotextiles, the crushed stone base of the path easily sinks into the soil layer beneath it, provoking the formation of voids and subsequent destruction. The use of geotextiles allows you to keep the rubble in place and prevent the consequences;

- effective moisture removal off the track due to the high moisture permeability of geotextiles;

- protection destructive tracks tree roots and shrubs;

- protection against sprouting weeds;

- increased resistance to stress;

- dirt protectionsince the soil and sand are separated;

- soil strengthening on the slopes;

- the possibility of local repair of the track.

Geotextiles are lightweight, easy to transport and install, but they are afraid of ultraviolet radiation, therefore it is better to work with them as quickly as possible.

Types of geotextiles by material

Geotextiles are used not only in the arrangement of garden paths - it is necessary in the construction of roads and foundationswhen performing drainage work. For all these cases, material with different properties is needed. That is why geotextile production technologies and materials used vary.

By the type of raw materials used, geotextiles are:

- polyester (polyester) geotextiles are made from thin polyester fibers. It turns out environmentally friendly, but not very durable material, which does not withstand the effects of many environmental factors, is afraid of acids and alkalis;

- polypropylene geotextile more strong and durable, resistant to the environment, excellent moisture conductivity, does not rot;

- mixed geotextiles as a part has safe recyclables, including threads of cotton and wool. It turns out cheaper material, but much less strong and durable than its analogues. Natural threads quickly rot, forming voids and reducing the effectiveness of the use of geotextiles.

For garden paths, geotextiles made of polyester or polypropylene are suitable.

Types of geotextiles according to manufacturing technology

Depending on the characteristics of production, geotextiles are:

- needle-punched obtained by bonding polypropylene or polyester fibers in a special way, thereby achieving the ability to pass water along and across the fiber. The material will not be clogged with soil particles and filled with water;

- thermally bonded obtained by fusing fibers with each other, due to which a record strength is ensured, but weak filtering capabilities - water passes only in the transverse direction;

- knitting stitching obtained by interweaving fibers. It passes water well, but does not withstand the effects of many external factors, unstable.

For garden paths, it is best to take needle-punched geotextiles, although many allow the use of thermally bonded material.

Geotextile Density

When choosing geotextiles for garden paths, it is imperative to pay attention to the density of the material. It is believed that the higher this indicator, the better the material in front of you. Density ranges from 17 to 600 g / m2 and more. The thinnest geotextiles are used as soil protection against birds, to cover greenhouses and greenhouses.

For the organization of garden paths, a material with a density of 100-250 g / m is useful2. The choice is best made on the basis of analysis of the type of soil and the characteristics of the site. So, if the territory is flat and the soils are stable, then it will be sufficient to use geotextiles of 100-150 g / m2, if the soil is mobile and unstable, it is better to take geotextiles with a density of 250 g / m2 and even more. In most cases, they stop at the option of 150-200 g / m2 - This is an excellent ratio of strength and price.

How to lay geotextiles

Of course, it’s not enough to choose high-quality geotextiles - it is still necessary to correctly assemble it to ensure the stability of garden paths. Track coverage can be any: asphalt, tile, wooden saw cuts, gravel, stone, decking, brick, etc. For example, consider the use of geotextiles for the installation of paths from paving slabs:

- the boundaries of the future track are marked on the ground. In some cases, it makes sense to lay the tile on unprepared soil, but you can do without it;

- excavation to a depth of 35-40 cm (depends on the thickness of the sand, gravel layer and the tile itself);

- all rubbish, tree roots are removed from the bottom of the trench, carefully rammed;

- laying geotextiles at the bottom of the trench, overlapping paintings - at least 20 cm, the material should also cover the walls of the trench and go to the surface by 5-10 cm. For fixing, you can use stones or other improvised objects;

- layered layer crushed stone about 15 cm, carefully leveled;

- crushed stone is covered with another layer of geotextile;

- poured fine sand with a layer of about 10-15 cm, it is tampered with quality, and tile laying takes place on it. Many masters recommend that the laying layer be made from a mixture of M500 cement and sand in a ratio of 1: 4, i.e. where 10 cm can only be covered with sand, the remaining 5 cm with a mixture;

- the tile is rammed with a rubber mallet, well penetrated into the mixture, trimmed if necessary, the seams are covered with the same cement-sand mixture or sand;

- remnants of geotextiles are trimmed, installed borders.

Even if it happens that some tile sags, you can get by with a local quick repair. The tile rises, sand is poured under it, the tile is installed back and rammed.With proper installation, repairs will have to be carried out extremely rarely.

Note that there are many manufacturers of geotextiles on the market, so listing at least some of them is very difficult. When buying, do not be lazy to study product reviews so that the work performed is not in vain.