8 tips for choosing geotextiles: types, purpose and manufacturers

Today, construction of roads, airfields and buildings, as well as drainage and garden and summer cottage works are not complete without geotextiles. Initially, the material was used only to prevent mixing of different layers of substances - today geotextiles are also widely used for drainage and reinforcement. This is a moisture resistant, durable, resistant to decay and aggressive media material, which is now available in a wide range. Geotextiles differ mainly in strength, production technology and the type of material used for its manufacture, which largely determines its properties and scope. How to choose geotextiles for drainage, landscape work or arrangement of paths? What types of geotextiles exist, and which manufacturers offer really high-quality products? We deal with all the nuances of the right purchase.

No. 1. Geotextile production technology and its properties

Geotextiles, one of the types of geosynthetics, are made from synthetic raw materials, often used polyester and polypropylene yarns, other polymers and fiberglass. The method of production of geotextiles and, therefore, the main qualities of the finished material and the scope of its application depend on the feedstock.

The most durable geotextile obtained from polyester and polypropylene yarns. Also on sale you can find material from blended yarns, in the production of which waste from the textile industry is used. If cotton or wool threads were mixed, then for drainage work this material is not particularly suitable, as it wears out quickly, and for garden and landscaping - It will do. If the manufacturer used glass inclusions, then the strength of such a geotextile will be at its best.

According to the method of production, geotextiles are divided into such types:

- needle-punched. This material is called the most suitable for organizing drainage. It passes water well due to elastic pores and can be used on almost any type of soil;

- thermally bonded (thermofixed). The material is characterized by high strength, durability, resistance to moldbut it passes water mainly in the transverse direction. It can be used to organize drainage on stony soils and on soils with a high content of large sand. It is also used to strengthen slopes, paving stones and in weed control;

- knitting stitching The method is used for the production of geotextile, a subspecies of geotextiles. It is produced by weaving synthetic fibers, as a result, a durable material is obtained, which is used mainly for strengthening and reinforcing, but not for drainage.

No. 2. Types of geotextiles: geo-fabric and geo-cloth

Geotextiles are divided into two groups:

- geo-canvas;

- geotextile.

Geofabric made by knitting and piercing method. Threads of different strengths (1-3 mm thick) are twisted at right angles, which allows to achieve strength and elasticity, but the final strength directly depends on the density of the fibers and the distance between them.The geo-fabric turns out to be elastic, tear-resistant (withstands up to 1000 kN / m2) and with a low rate of permeability. It is used to reinforce and increase the bearing capacity of soil in the construction of roads, airfields, solid waste landfills, as well as in the organization of steep slopes, in civil engineering and landscape design.

Geopolit - non-woven material that is produced by needle-punched or heat-bonded method from polyester, viscose, polyamide, polypropylene or other polymer fibers. Such material is characterized by low strength, but decent elasticity and water permeability, therefore it is universally used for organizing drainage, filtration and as a separator between different layers.

No. 3. Density of geotextiles and scope

Density is the most important parameter of geotextiles, on which the degree of elasticity and water permeability depends. Density is selected based on from the type of soil and the objectives of the work performed:

- 17.3 g / m2 - transmits water and light, is used to protect seeds from birds by laying on the ground surface;

- 42.6 g / m2 - it is used at arrangement greenhouses and greenhouses. He like film, stretched to the frame. Transmits light and water;

- 60 g / m2 - can be used as a filter in the arrangement of the drainage system, but is more often used in agriculture and summer cottage farming as a measure of weed control. They cover the surface of the earth, make cuts for cultivated plants. Due to the fact that the material passes the moisture necessary for the root system of the plant being grown, but does not allow sunlight, weeds do not develop;

- 100 g / m2 - suitable for use with ponds, flower beds, decorative slopes and for other landscape works;

- 150-200 g / m2 - used to separate layers in the arrangement of drainage systems, as well as in the construction of foundations, sidewalks, pools and other artificial reservoirs in a summer cottage;

- 250 g / m2 - suitable for the construction of roads and parking lots for passenger cars;

- 300 g / m2 - for roads and parking lots of freight vehicles;

- from 350 g / m2 - for railways, busy highways, runways for small aircraft;

- from 400 g / m2 - for the construction of runways at airports of international importance.

In private construction, it makes no sense to use expensive dense material - geotextiles with a density of 200 g / m are called universal2with which the drainage system can be organized, and most of the landscaping work. In conditions of unstable soils, it is recommended that geotextiles be fully drained with 300 g / m2, and simple landscape work can be done with material with a density of 100 g / m2.

Geotextiles are available in rolls from 2 to 5.2 m wide with material winding from 30 to 130 linear meters. You should choose, starting from the scale of the work carried out so that as little waste as possible remains. Rolls are packed in black plastic film with UV protection - its integrity is extremely important.

Number 4. Choosing geotextiles for drainage

When a country house is located in a lowland, high groundwater area, or in close proximity to a natural reservoir, it is necessary to protect the territory from the negative effects of a seasonal increase in groundwater level. They can lead to leaching of soil from under the foundation and the formation of voids, which threatens disastrous consequences. In addition, increased soil moisture can harm some fruit trees and ornamental shrubs. To prevent such an outcome, it is necessary to equip the drainage system, in which geotextiles are given the most important place.

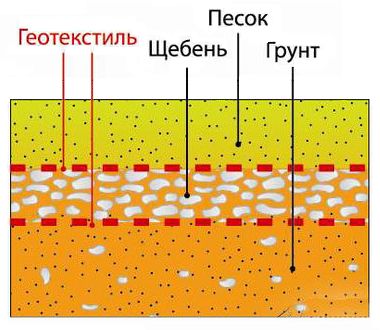

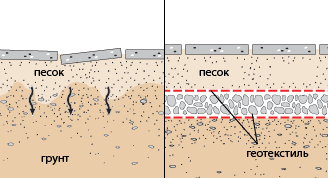

The drainage system consists of pipes and a storage well. Drainage pipes are placed in a layer of gravel, which can gradually silt with soil and sink into the soil.To prevent this from happening, geotextiles are needed, which in this case plays the role of a filter and ensures the stability of the entire system. The principle of arranging drainage is to create a trench, cover it with a layer of gravel of about 15-20 cm and lay geotextiles on it. After this, another layer of gravel is poured with a thickness of about 20-25 cm, drainage pipes run through it. The remnants of the geotextile are poured over each other, and the trench is covered with previously excavated soil.

Experts recommend that geotextiles be removed from packaging only before direct use and as soon as possible after falling asleep, since ultraviolet rays act destructively on the material. They lay the material freely, without tension and creases, overlap of canvases 30-60 cm.

Regarding which geotextile is better for drainage, needle-punched or thermally bonded, experts hold diametrically opposed opinions. Fans of needle-punched say that glued geotextiles do not have sufficient bandwidth and can only be used on rocky soils. Other experts advise thermo-glued, recalling that it is usually used for drainage in private construction in Europe, and that it is not so quickly clogged with soil. In domestic conditions, needle-punched geotextiles are most often used for these purposes.

To ensure high-quality drainage and durability of the entire system, the material should be:

- density 100-250 g / m2;

- withstand tensile stress of 100-600 kN / m2;

- have a filtration coefficient of 50 m3/day.

No. 5. Geotextiles for roads and sidewalks

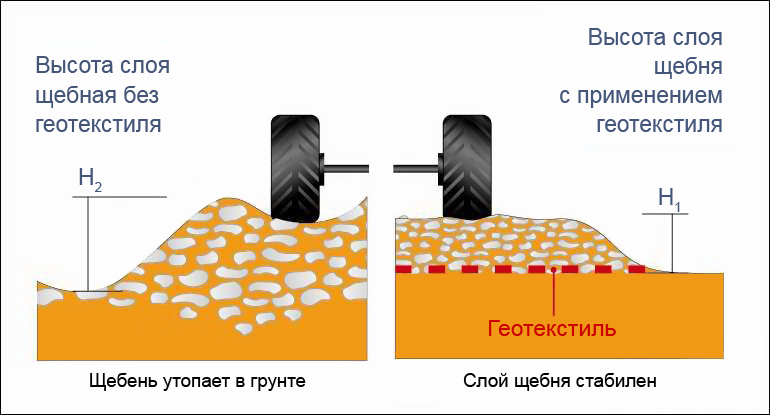

In the construction of roads and sidewalks, geotextiles are used as reinforcing and separation layer. It prevents siltation of the bulk layer, provides an even distribution of the load, does not allow dips to form when passing heavy equipment. If you do not use geotextiles in the construction of the road, then under the influence of groundwater and rain flows, the canvas will quickly sink under the trucks. Moreover, geotextiles make it possible to lay highways in areas with weak bearing and soft soil, which is especially important, given the large length of roads. In areas where there is a great danger of mudflows, it makes sense to use a geogrid layer instead of geotextiles, which has more pronounced reinforcing properties.

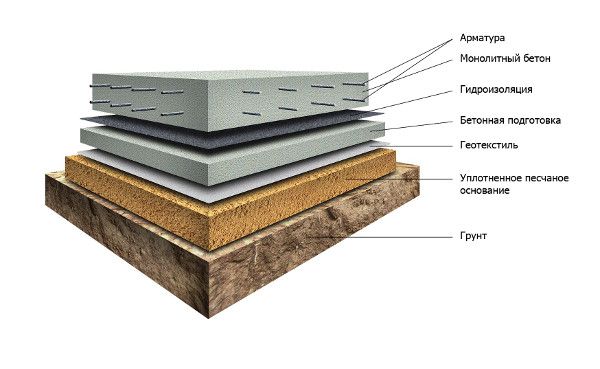

Indispensable geotextile for arrangement of footpaths, in particular tiled or paving stones. Without a layer of geo-cloth, the ground under the tiles will gradually be washed out and sag under the influence of rain flows, and the durability of the coating is unlikely to exceed 8-10 years - the use of geotextiles can solve this problem. Under the paving slabs, it is necessary to remove the soil layer, tamp the bottom well, cover it with a layer crushed stone 5-7 cm, and then lay the geotextile, on top of which quarry sand is poured - the basis for laying tiles. Geo-canvas serves as drainage and separator layers. For pedestrian pavement roads choose a material with a density of 150-200 g / m2.

No. 6. Geotextiles in landscape design

In garden-landscape works, geotextiles have found huge distribution and is used for such purposes:

- at arrangement of artificial reservoirs to strengthen the walls, protect slopes from water erosion and as a protection of the waterproofing layer from damage. In this case, it is better to take thermally glued material with a density of 250-400 g / m2;

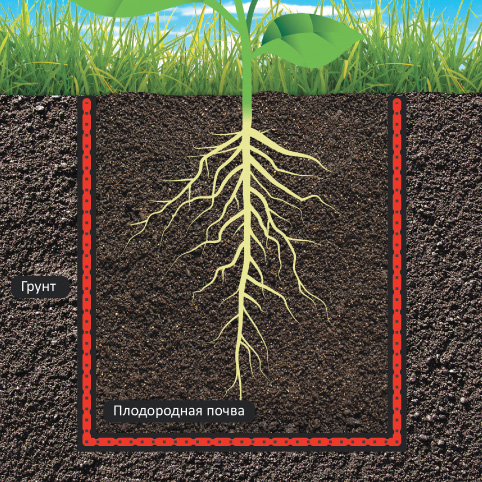

- for growing varieties of plants and trees, which cannot grow on the site due to the fact that the soil is too alkaline or clay. In this case, at the planting site, the soil layer is taken out to the depth of the future root system, the geotextiles are laid and covered with the soil that is suitable for growing the desired plant variety. Geopolit will play the role of a barrier;

- when arranging tracks from wood chips, sand, gravel or grass, geotextiles with a density of 150-300 g / m2 will perform barrier and drainage functions, preventing the layers from mixing and drowning bulk track after the rain;

- to protect planted seeds from birds. Such material simply covers the soil, it is important to take geotextiles with a minimum density so that it passes the sun and moisture;

- for the construction of greenhouses and greenhouses.

Number 7. Geotextiles in private construction

In private suburban construction, as well as in large-scale housing, it is already difficult to do without geotextiles. It is used:

- when arranging the foundation to give it greater strength, protection from negative factors, to evenly distribute the load on the soil and prevent soil deformation. Density is chosen from 150 to 400 g / m2, and a more accurate value depends on the type of soil, foundation and at home. For example, for a pile-screw foundation, a material of minimum density is required, and for a shallow-buried and others, it is already denser;

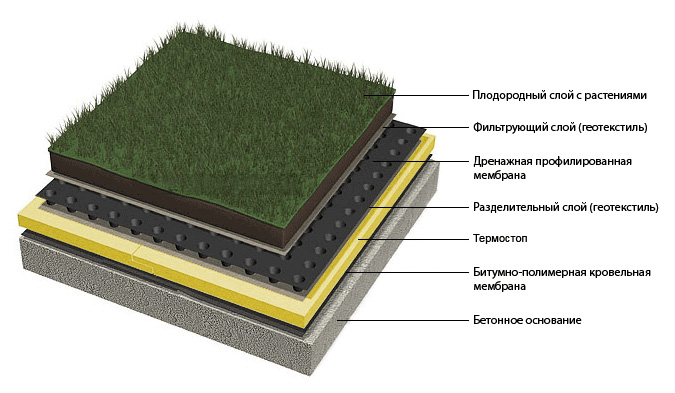

- for flat roofs of inversion typethat differ in the ability to break there lawn or relaxation area. The design of such a roof is based on concrete slabs or a monolith, a layer of bitumen waterproofing, drainage to remove excess moisture, a layer insulationon top of which geotextiles are mounted. On top of it make a sand-cement pillow under the paving slabs or pour a layer of fertile soil for growing lawn;

- when laying underground utilities geotextiles are used to protect the heat and waterproofing layer of pipes from clogging with sand and soil;

- at arrangement children’s and sports fields, sandboxes and other simple structures to ensure free passage of water and as a layer separator.

Number 8. Large manufacturers of geotextiles

The choice of geotextiles in the Russian market is huge and it is represented by products domestic and foreign manufacturers. To choose geotextiles of proper quality, it is better to pay attention to the products of companies with a name, which in itself is already a guarantee of quality. You can trust the products of the following manufacturers of geotextiles:

- GC "Polymerholding" - a domestic manufacturer that produces geotextiles under the trademark "Dornite". Its products are so popular that the brand name has already become a household name for the entire geotextile. The company produces woven and non-woven geotextiles of various densities;

- LLC Nomateks - domestic enterprise, produces needle-punched geotextiles with a density of up to 800 g / m2 and roll width up to 5 m;

- LLC "Geotex Group" - Another large domestic enterprise specializing in the production of geosynthetics for road construction, also produces geotextiles for private construction, the arrangement of reservoirs, drainage systems, and the construction of sports grounds;

- Avantex LLC produces needle-punched geotextiles from primary and secondary raw materials, uses mainly polyester and polypropylene, density from 100 to 600 g / m2, roll width from 1 to 6.3 m;

- Dupont - A large American chemical company, which in particular produces geotextiles under the brand name Typar. The material is of the highest quality and durability, is in demand in the domestic market. It produces non-woven geotextiles, and under the Typar SF brand they produce innovative geotextiles, which have amazing uniformity;

- NETEX A - Czech manufacturer of needle-punched geotextiles, average prices, high quality, products are presented in a wide density range.

In addition, the products of the domestic company OAOMontem"(Non-woven geotextile), Austrian Polifelt, international concernFreudenbergPolytex»And the British manufacturer Terram. When buying, be sure to carefully study the packaging, where all the characteristics of the products are indicated, and do not forget to think in advance about the method of transportation: small rolls can be taken away in a passenger car, but rolls with a width of 4.3 m or more will be more problematic to deliver.