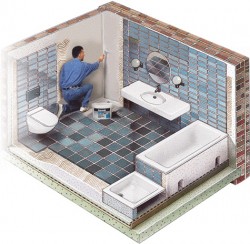

Do-it-yourself bathroom waterproofing

Why waterproofing a bathroom?

The waterproofing of the bathroom is critical stage repair work, since this is a room in which there is a high concentration of moisture. Waterproofing is necessary to ensure a more durable operation of the finishing materials and supporting structures of the building. It will not allow seams to open or provoke the appearance of cracks.

The waterproofing of the bathroom is critical stage repair work, since this is a room in which there is a high concentration of moisture. Waterproofing is necessary to ensure a more durable operation of the finishing materials and supporting structures of the building. It will not allow seams to open or provoke the appearance of cracks.

In addition, the possibility of flooding of the neighbors through the same microcracks or other defects of the ceilings and walls will be minimized. Such a nuisance can occur even if a small amount of water has been spilled on the floor. Waterproofing finish helps to avoid such troubles. In addition, moisture falling into cracks and places that are not protected from water evaporates very slowly.

It also reduces the likelihood of mold and mildew, which can occur in hard-to-reach places, due to the accumulation of excess moisture there. Therefore, if you care about your health and the health of those close to you, waterproofing is necessary. Modern materials and methods make it possible to provide complete comprehensive protection against penetration of moisture into the walls and the base of the bathroom floor.

Waterproofing Methods

Before you begin work on waterproofing, you should decide who will conduct all stages of repair work. If you want to independently carry out these works and not involve specialists in order to save money and make repairs with a minimum budget, you should familiarize yourself with the main stages of waterproofing. Knowledge is also requiredabout waterproofing materials and methods for applying or styling them. So, let's look at the basic methods of protecting a bath room from moisture penetration into the base of walls and floors.

Before you begin work on waterproofing, you should decide who will conduct all stages of repair work. If you want to independently carry out these works and not involve specialists in order to save money and make repairs with a minimum budget, you should familiarize yourself with the main stages of waterproofing. Knowledge is also requiredabout waterproofing materials and methods for applying or styling them. So, let's look at the basic methods of protecting a bath room from moisture penetration into the base of walls and floors.

- Painting method - This method of waterproofing is the most economical, since bitumen solution is used here. This material is one of the most affordable building materials in the modern market and is easy to use. It is good enough to smear all sections of the walls of the bathroom to get good protection.

The disadvantage of this protection is fragility, service life - 5-7 years. This is, quite a bit, given that many expect to make repairs for a longer period. But for those who love change and change the interior of the bathroom every few years, such waterproofing is quite suitable and will save money. - Coating method - this method is also simple to implement, but it is better that it is performed by a specialist. To waterproof the bath with this method, bitumen mastic with additives from polymer or rubber materials is used, which makes the material more durable in use and an effective waterproofing agent. When carrying out work, applyprotection layer not less than 3 mm.

- Okanechny method - in this case, a bitumen solution based on polymer additives is used for gluing reinforced polyester or fiberglass to the walls of the bath. These materials paste over all surfaces of the walls of the ceiling and floor of the bathroom.The work is carried out by heating the adhesive mass or by the cold method, depending on the type of bitumen solution chosen. Waterproofing in this case has good efficiency.

- Impregnated waterproofing, penetrating waterproofing - presented on the market with many options. One of the effective ways is to impregnate the concrete or plastered walls of the bathroom with a special compound, which can easily be purchased at the construction supermarket. Impregnation penetrates deep into the wall and creates a protective layer that protects the surface from moisture. This is a fairly simple way for independent work. No special skills are required for impregnation work.

Waterproofing by roll materials

You can do the waterproofing of the bathroom with your own hands without much effort, since there is nothing complicated in carrying out repairs. You should carefully study all the main stages of the work and feel free to proceed with them. One way is pasting the surface of the walls bathroom roll waterproofing materials. Self-adhesive waterproofing is very popular, which is easy to install and practically does not require special skills, so it is ideal for independent work.

You can do the waterproofing of the bathroom with your own hands without much effort, since there is nothing complicated in carrying out repairs. You should carefully study all the main stages of the work and feel free to proceed with them. One way is pasting the surface of the walls bathroom roll waterproofing materials. Self-adhesive waterproofing is very popular, which is easy to install and practically does not require special skills, so it is ideal for independent work.

Self-adhesive waterproofing is easy to install - a fragment of the roll material of the required size is cut off and laid on the wall around the entire perimeter of the surface of the bathroom or where you protect against moisture. Followed by good go roller on a self-adhesive tape so that the material adheres to the wall and holds firmly. The following fragments of protective roll material are overlapped by approximately 4-5 cm. A significant overlap is provided at the junction of the floor and wall, which should be at least 15-20 cm on the wall.

In a similar way installation of roll waterproofing, but a weld-in methodwhich requires special burner skills. It is not difficult, but without certain experience it will be difficult to carry out the work yourself. The roll of material is unwound to the desired configuration and is bonded to the surface of the wall, floor of the bathroom by welding. The bitumen layer on the material is melted and thereby glues securely to the surface of the wall.

After carrying out the gluing of walls and floors with rolled materials, a concrete screed should be created on the floor of the room. It should be borne in mind that the floor level in the bathroom will differ from the floor level of other rooms and this should be noted.

Waterproofing with coating materials

Lubricants are best suited for self-protection against moisture. The modern construction market offers a lot of ready-made mixtures that can immediately be applied to the surface of the base of the walls and floor. That is, the advantage of this type of waterproofing in itsuniversality. Lubricants will significantly reduce the time for repair work, unlike rolled materials. Repairs will be faster and budgets will be lower.

Lubricants are best suited for self-protection against moisture. The modern construction market offers a lot of ready-made mixtures that can immediately be applied to the surface of the base of the walls and floor. That is, the advantage of this type of waterproofing in itsuniversality. Lubricants will significantly reduce the time for repair work, unlike rolled materials. Repairs will be faster and budgets will be lower.

There are two types of coating materials - based on bitumen or cement

- Bituminous mastics used for a long time and have good moisture protection. Modern bituminous mixes for waterproofing are divided into two types - this is bitumen-rubber (rubber) and bitumen-polymer. Both types have excellent adhesion, i.e. good adhesion to the surface. These mastics use oxidized bitumen with the addition of organic and other fillers, which increase the effectiveness of the waterproofing properties of the material.

- Cement coating material made from cement itself with the addition of mineral-based fillers. Waterproofing cement materials can be divided into two types - this is one-component and two-component. The former have a loose consistency and are diluted with water, while the latter are ready-to-use. A bonding component in a two-component cement coating is polymer-based latex. These coatings have good waterproofing properties and are used everywhere.

Before applying cement materials, the wall surface is pre-moistened. Next, apply the first layer, and then a couple more layers (you need to apply 2-3 layers). Between the application of layers, a break is made so that the coating is good absorbed into the surface. Cement coatings tend to penetrate deep into the surface structure, which has a good effect on the effectiveness of waterproofing. The approximate consumption of the cement mixture is 3 kg per square meter. Good elasticity indicators of cement coating materials allow to apply them on different surfaces.

Stages of waterproofing walls

Before waterproofing the bathroom, carefully prepare the surface of the walls for implementation repair work. Floor and walls should treat with solutionconsisting of a cement-sand mixture. Should close all cracks, troughs and surface irregularities. It should be smooth and high-quality screed, to the maximum good and high quality plaster the walls. After that, remove all excess debris and dirt from the surface of the walls and floor and spend primer. This will allow waterproofing materials to better interact with the surface, that is, have good adhesion to the wall or floor.

Before waterproofing the bathroom, carefully prepare the surface of the walls for implementation repair work. Floor and walls should treat with solutionconsisting of a cement-sand mixture. Should close all cracks, troughs and surface irregularities. It should be smooth and high-quality screed, to the maximum good and high quality plaster the walls. After that, remove all excess debris and dirt from the surface of the walls and floor and spend primer. This will allow waterproofing materials to better interact with the surface, that is, have good adhesion to the wall or floor.- Next comes applying a waterproofing composition to the wall surface. Carefully read the instructions of the composition that you have chosen to work. Apply the mixture evenly to the surface with a brush. Particular attention needs to be paid to places where joints, corners and other hard to reach places. There you can apply a double layer to get more effective protection and to prevent the penetration of moisture in such places. You can also use reinforcing materials, such as reinforcing material in the form of a reinforcing tape, which is superimposed on a corner or joint.

- After the waterproofing material is applied to the surface of the walls, you should wait at least a day for the materials settled and hardened. Then proceed to ceramic tiles or other material, such as plastic. When tiling, you can use a special waterproofing adhesive, which will increase the effectiveness of protection against moisture. Stitches between tiles should also be treated and coated with a special waterproofing compound. The corners of the bathroom can be further protected with ceramic corners and sealant.

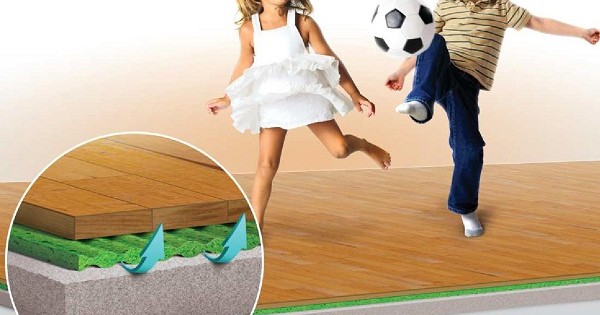

Stages of waterproofing the floor

This stage of work is very important for waterproofing the bathroom, since all moisture accumulates on the floor, which can go into the ceiling or floor. If you live in a panel house, then the lack of waterproofing in the bathroom can lead to flooding of the neighbors. As a result, significant financial costs if a pipe breaks or a leak occurs. Therefore on protection against moisture penetration into the base the bathroom floor should not be saved and a full range of work should be carried out using modern waterproofing materials.

This stage of work is very important for waterproofing the bathroom, since all moisture accumulates on the floor, which can go into the ceiling or floor. If you live in a panel house, then the lack of waterproofing in the bathroom can lead to flooding of the neighbors. As a result, significant financial costs if a pipe breaks or a leak occurs. Therefore on protection against moisture penetration into the base the bathroom floor should not be saved and a full range of work should be carried out using modern waterproofing materials.

- First of all should carry out preparatory work for cleaning the floor from debris, dirt.

- Then hold surface leveling. The floor should not have cracks, dents or other similar defects. Self-leveling devices are used for this.cement mixeswhich are very easy to use. Spend on your own floor leveling under the force of any man. Once the floor has been leveled and cleaned, it is time to carry out waterproofing work.

- Should choose type of waterproofingto be used for the entire bathroom and apply it. You can also combine various types of waterproofing materials and technologies. It can be like gluing floor waterproofing, which is carried out using roll waterproofingand roll waterproofing, using appropriate materials. Savings in materials can reduce the effectiveness of protecting the bathroom floor base from moisture, so choose quality materials from trusted manufacturers. It should be noted that paint waterproofing for the floor is practically not used, since it has a short life.

Take the floor waterproofing very carefully, as this will avoid unpleasant consequences in the event of leaks or pipe breaks. Why risk and pay the affected party in case of flooding. The bulk of the moisture goes to the floor, so a multilayer and high-quality waterproofing of the floor will protect against moisture penetration.