DIY waterproofing the foundation

General rules and waterproofing technology

Creating a solid foundation is an important task in the construction of any house, because a reliable foundation will carry a structure that can serve more than one generation of people. To make this possible, you should very carefully approach the protection of the foundation from moisture, that is thoroughly waterproof according to all building rules and preferably with the use of modern building materials.

Creating a solid foundation is an important task in the construction of any house, because a reliable foundation will carry a structure that can serve more than one generation of people. To make this possible, you should very carefully approach the protection of the foundation from moisture, that is thoroughly waterproof according to all building rules and preferably with the use of modern building materials.

A well-made waterproofing will create conditions for the durability of the structure, creating a favorable microclimate that will be dry and warm. This will make your stay in the house comfortable and save a lot of money on heating. To carry out work on protecting yourself from moisture on your own will be quite realistic. To do this, you should know the basic rules and technological nuances of such work.

Waterproofing Rules

The main foundation of the house, which will support the entire structure of the building, requires a careful approach to the calculation and conduct of all stages of work. Successful waterproofing requires knowledge of the processes occurring in the ground and in concrete. Knowledge of all the properties and capabilities of other building materials that will be used in carrying out hydraulic protection will be necessary for independent work.

- Any foundation buildings are waterproofed from underground groundwater and surface water (precipitation). In the first case, the depth and seasonal rise of groundwater should be taken into account. If the groundwater level is higher than the base of the foundation, then in addition to waterproofing, a drainage system should be constructed from pipes, which will remove excess moisture from the structure. A proper and well-made drainage system will effectively drain water and reduce moistureas well as hydrostatic pressure on the foundation. This is very important, since one waterproofing the base of the house will not be able to provide full protection in this case. In the case of protection from rainfall, a blind area is being constructed, which protects the building from external moisture in the form of rain and other precipitation.

- The next point is water compositionthat will be in the ground. There are so-called aggressive waters that have a greater destructive effect on the foundation. Therefore, you should carefully approach this issue and choose the appropriate building material, which has additional resistance to aggressive environments.

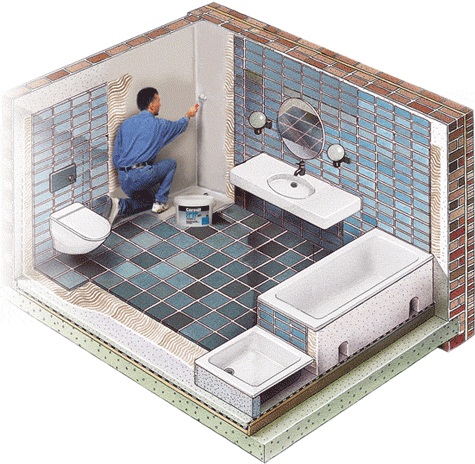

- According to the existing modern technology, it is necessary to carry out not only waterproofing of the main foundation structure, but also basement walls and floors, as well as cap. The moisture protection layer should be continuous along the entire perimeter of the surface, without breaks. From the outside and in places where there is an intense hydrostatic pressure, you need to double or triple waterproofing. That is, create multiple layers for greater efficiency.

Types and methods of waterproofing

There are two ways to waterproof the foundation - this antifiltration and anticorrosive. In the first case, it is impossible to carry out independent waterproofing, that is, to do everything with your own hands, since its arrangement requires high-class specialists who have experience and will do everything right.

In most cases, such protection is not required, therefore, for waterproofing with your own hands, it is better to use the second method - anticorrosive moisture protection. This method is used in most cases, for houses, baths, garages and other buildings. In turn, the anti-corrosion protection is divided into two types - this is horizontal and vertical hydrosolation. We will consider both types in more detail below.

Horizontal waterproofing

This type of waterproofing is important in the process of protecting against moisture of any small structure. Be it a bathhouse, a country house, a cottage and other similar building construction. Often used in a monolithic (solid) or strip foundation, where it is produced in two places.

This type of waterproofing is important in the process of protecting against moisture of any small structure. Be it a bathhouse, a country house, a cottage and other similar building construction. Often used in a monolithic (solid) or strip foundation, where it is produced in two places.

The first is below the level of the basement floor in order to prevent moisture from entering the soil. It is carried out at the level of 15-20 centimeters of the upper level of the basement floor surface.

The second is the junction of the foundation with the wall. It is done in order to prevent moisture penetration into the wall and accordingly prevent its destruction. Also horizontal waterproofing is used in the basement.

Preparation and laying of horizontal waterproofing

Laying horizontal waterproofing begins at the very beginning of the construction of the house. Once dug a pit for the foundation, which implies the presence of a basement, the implementation of waterproofing begins. At the bottom of the pit clay layer is falling asleep about 20-30 centimeters.

Laying horizontal waterproofing begins at the very beginning of the construction of the house. Once dug a pit for the foundation, which implies the presence of a basement, the implementation of waterproofing begins. At the bottom of the pit clay layer is falling asleep about 20-30 centimeters.

You can use sand, but the first option is better, since clay prevents the penetration of moisture. The layer is well compacted and prepared for pouring the next concrete layer. Next is a layer of concrete with a thickness of 5-7 centimeters in order to create a waterproofing layer of roofing material and bitumen mastic. Before laying waterproofing on a concrete surface, allow a fresh layer of concrete to settle.

This will take about 10-15 days for complete hardening and adaptation to environmental conditions. Next, the concrete surface is covered with bitumen mastic over the entire surface area and a layer of roofing material is laid next. This is repeated again, that is, the second layer of bituminous mastic and roofing material is carried out. Then a second layer of concrete of the same thickness (5-7 centimeters) is poured.

After laying the last layer of concrete, it should be ironed. This process is carried out in this way - after concrete poured need to wait about 3 hours and pour a layer of pure cement (1-2 centimeters) on a fresh concrete surface. Cement should be sieved through a fine sieve. Then the cement layer should be leveled and after it gets wet and absorbed, sometimes moisten with water, as happens when creating a concrete screed.

Drainage system

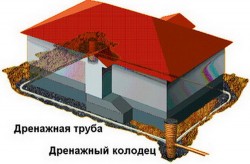

For places where high humidity, even multi-layer waterproofing will not protect against the gradual penetration of moisture into the house. This usually happens in wetlands and where rainfall regularly occurs. To take away the extra wag a drainage system should be built. This is a pipe system, which is built in such a way as to remove excess moisture from the site with the house and thereby protect the home from destruction.

For places where high humidity, even multi-layer waterproofing will not protect against the gradual penetration of moisture into the house. This usually happens in wetlands and where rainfall regularly occurs. To take away the extra wag a drainage system should be built. This is a pipe system, which is built in such a way as to remove excess moisture from the site with the house and thereby protect the home from destruction.

Before the construction of the drainage system, it is necessary to find out the level of groundwater and the average amount of precipitation falling over the year. To implement this system, you should dig a trench around the entire perimeter of the object (houses, villas, baths). The distance from the trench to the object should be at least 0.7 meters.The width of the dug groove will be 30-40 centimeters, and the depth depends on the moisture level, that is, at the depth where a water mirror is formed.

It is very important that the trench is located at a slope to the place of moisture concentration (well or drain pit). The slope should be about 1 centimeter per linear meter of pipes. The drainage system can be completed if necessary after the completion of the construction of the house.

Vertical waterproofing

From the name it is clear that this type of waterproofing is used on vertical surfaces, that is, the walls of the foundation. It contains many ways to waterproof the surface, thanks to the different types of appropriate materials that are used to protect the foundation from moisture. Vertical waterproofing can be painting, gluing or mixed.

For example, coating a surface with liquid bitumen belongs to the painting method, and protection with roofing material can be attributed to the gluing method. The combination of different options will create a more reliable and effective protection against penetrating from the soil and along with rainfall. Consider each type of vertical waterproofing separately.

Bituminous waterproofing

This method is the easiest to implement and the least expensive. For the performance of work, bitumen resin is used, which is easy to purchase in construction stores. Distinguish between cold and hot bituminous mastic. In the first case, preparing the mixture is not required, since it is sold ready-made, so you can use it right away. With the hot method, it is required to purchase briquettes with hardened resin and prepare bituminous mastic using additional means.

This method is the easiest to implement and the least expensive. For the performance of work, bitumen resin is used, which is easy to purchase in construction stores. Distinguish between cold and hot bituminous mastic. In the first case, preparing the mixture is not required, since it is sold ready-made, so you can use it right away. With the hot method, it is required to purchase briquettes with hardened resin and prepare bituminous mastic using additional means.

This is the cheapest way to waterproof the foundation. To prepare bituminous mastic in a hot way, you will need the original material itself - resin in briquettes and used oil in the proportions of 70% (bitumen) and 30% (used oil). It also requires a capacity in which the heating of the bitumen mass will occur. After the mixture boils and stops bubbling, you can begin to process the surface of the foundation of the house.

It is necessary to lubricate from the very base of the foundation and above the soil boundary by 20-25 centimeters. It is necessary to apply several layers so that the total thickness of the protective coating is about 5 centimeters. Bitumen mastic penetrates well into all cracks and joints, sealing them. Its service life is 5 years, which is a short period. Then it will begin to crack and let water into concrete. To significantly extend the life of the protective layer, it is recommended to use bitumen-polymer mastics.

Rolled waterproofing (roofing material)

This type of protection is used as an additional barrier preventing the penetration of moisture into the foundation. Roll waterproofing is carried out on top of the bitumen layer to improve protection against groundwater. Under roll waterproofing understand application of roofing material, which has a roll look and is a kind of canvas. Also, this material is called technoelast and isoelast.

This type of protection is used as an additional barrier preventing the penetration of moisture into the foundation. Roll waterproofing is carried out on top of the bitumen layer to improve protection against groundwater. Under roll waterproofing understand application of roofing material, which has a roll look and is a kind of canvas. Also, this material is called technoelast and isoelast.

The coating process is as follows - a roofing material is applied to the bitumen mastic layer, which is preheated with a special burner. As soon as the surface of the roofing material is heated and has taken a state ready for sticker on the foundation, the overlay and fixation of the rolled material on the surface, requiring waterproofing, takes place. The joints of the edges of the roofing material are overlapped by about 20 centimeters and processed by the burner. The positive point of using roll-up (roofing material) waterproofing is its low cost and availability.

Longevity, which has an indicator of 50 years, should also be highlighted. This is a very impressive period and, together with bituminous hydrosolation, will create effective protection against groundwater and rainfall.The only negative is that it will be very difficult to independently install the roofing material, so you need the help of another person.

Stucco waterproofing

From the name it becomes clear that with this waterproofing a special putty is used, which is applied to the foundation and thereby creates a protective layer from moisture. Plaster waterproofing is used in conjunction with other types of protection, since the effectiveness of one plaster is not high. It is used, also for alignment of foundation walls, form additional protection.

From the name it becomes clear that with this waterproofing a special putty is used, which is applied to the foundation and thereby creates a protective layer from moisture. Plaster waterproofing is used in conjunction with other types of protection, since the effectiveness of one plaster is not high. It is used, also for alignment of foundation walls, form additional protection.

To create a water-repellent property, special substances are added to the plaster that create the desired protective effect. Putty should be applied in the usual way, as with other plastering works. A putty mesh is used, which is fastened with dowels to the foundation wall.

The advantages of stucco waterproofing can be distinguished by the low cost of materials and a fairly simple process of work, which a novice can handle. Cons are also present - this is a low hydrostability, the possibility of cracks and a service life of about 15 years.

Liquid rubber waterproofing

A modern type of waterproofing that does not require special skills when working on creating a protective layer and perfect for doing it yourself. Liquid rubber it is evenly sprayed over the foundation surface and creates an effective protective layer that will perfectly keep the foundation from moisture from the soil.

A modern type of waterproofing that does not require special skills when working on creating a protective layer and perfect for doing it yourself. Liquid rubber it is evenly sprayed over the foundation surface and creates an effective protective layer that will perfectly keep the foundation from moisture from the soil.

Before applying liquid rubber, the surface is thoroughly primed and then one of two types of material is applied - it is “elastomix” or “elastopase”. In the first case, after applying rubber to the foundation surface, the material solidifies quickly (about 2 hours). When opening the packaging with liquid rubber "elastix", further storage of the substance is impossible. Apply the material in one layer. "Elastopaz" is slightly cheaper than the previous material, but applied in two layers. This type of rubber is subject to storage, even after opening the package, therefore it is quite convenient when using construction teams. Rubber can be applied with a spray, if available, or in a simple way, such as a brush or roller.

The advantages of liquid rubber are the durability of the applied layer, excellent resistance to moisture and ease of application. The downside is the comparative high cost of the material. Also, when using manual application with a roller or brush, this is a rather long process. It is better to use a spray gun.

Screen waterproofing

With screen waterproofing, bentonite mats are used, which filled with clay and create excellent protection against pressure and aggressive groundwater. This type of waterproofing is a modern analogue of the “clay castle”, which is a layer of rammed clay that prevents water from seeping into the foundation. It is the easiest and most affordable way of waterproofing. It was used even before the appearance of modern building materials by our ancestors. Screen clay mats are attached to the foundation wall with a special pistol dowels. This method is used more often for non-residential buildings or in combination with other types of waterproofing.