Do-it-yourself water heating: is there any benefit and how to arrange?

For your home, did you choose water heating and decided to arrange it yourself? There is a lot of information on this issue. But to structure and process it in order to understand how to properly arrange water heating with your own hands can be a separate task, slightly inferior to the work on the heating device itself. We hope this article will clarify and help you independently arrange water heating in your home.

Let's start with the pros that this option has:

- Cost savings. But when calculating the financial benefits, be sure to take into account the time spent on installing the heating system, which maybe you could sell at a higher price and the cost of the tools needed to complete the installation work.

- You do for yourself, and therefore, in good conscience with the highest quality possible. Of course, it should not be lower than a certain level to ensure long-term operation of the system.

Your opinion about how you should have a water heating system will not be influenced by the opinion of the contractor who is interested in doing everything as he likes and conveniently, using familiar technologies and devices. But there are new products that are more economical and more convenient to use! For example, we recommend using Jaga water convectors with Low-H20 technology, which allows you to warm the heater to operating temperature in 10 minutes! The cast-iron battery, for reference, warms up at least an hour.

Your opinion about how you should have a water heating system will not be influenced by the opinion of the contractor who is interested in doing everything as he likes and conveniently, using familiar technologies and devices. But there are new products that are more economical and more convenient to use! For example, we recommend using Jaga water convectors with Low-H20 technology, which allows you to warm the heater to operating temperature in 10 minutes! The cast-iron battery, for reference, warms up at least an hour.

Therefore, it is advisable to do water heating with your own hands when:

- it is beneficial to do it yourself, taking into account all of the above factors;

- you have the skills for this job.

The last paragraph will dwell in more detail.

Skills and tools necessary for self-installation of water heating

All installation work of the water heating system can be reduced to several works:

- Installation of a water boiler (if an autonomous heating system is created).

- Installation of radiators.

- Installation of heating system pipes - connection between each other and with other elements of the system (radiators and boiler).

- Installation of fittings (manifolds, valves, air vents, filters, etc.)

Installation of a water boiler

Model dependent the boiler may be installed on the floor (floor type) or wall, it is necessary to create a concrete screed 3-5 cm thick. Therefore, the simplest skills are required concrete works. Of the tools and fixtures you will need:

Model dependent the boiler may be installed on the floor (floor type) or wall, it is necessary to create a concrete screed 3-5 cm thick. Therefore, the simplest skills are required concrete works. Of the tools and fixtures you will need:

- capacity for concrete mortar (bucket, basin);

- rule for smoothing the surface;

- level for checking the horizontal surface (the latter is very important!)

In the case of a wall-mounted boiler, work is reduced to drilling holes for anchor fasteners. The required tool is as follows:

- tape measure for marking the mounting points of the boiler;

- drill-perforator with a set of drills;

- plumb or level to check the vertical installation of the boiler.

Installation of radiators

Installation of these heating devices consists of the following:

Installation of these heating devices consists of the following:

- installation on a radiator of the Mayevsky crane (for air bleeding), through plugs, American women, plugs.

- drilling holes for mounting the radiator on the wall.

For these works, you need:

- flax or tape fum (for sealing a threaded connection);

- a set of keys or an adjustable wrench;

- tape measure for marking the mounting points of the heater;

- drill with a set of drills.

The main skills for installing radiators boil down to the need to properly install and configure hydraulic fittings, the ability to properly wind up flax or fum and work with a drill -puncher.

Installation of heating pipes

There are several types of pipes and methods for their installation, which determine the necessary skills and tools for installation.

There are several types of pipes and methods for their installation, which determine the necessary skills and tools for installation.

A. Plastic pipes

They are connected to each other or to radiators using:

- welding;

- compression fittings.

If you want to arrange a water do-it-yourself heating pay attention to the fact that in the first case special equipment is needed - for stripping pipe joints and directly welding. For the second type of connection, no equipment is required, but special fittings must be purchased. Therefore, if you do not have enough skills to work with welding equipment (which you still need to get somewhere else), choose a simpler connection option.

B. Plastic pipes

These pipes connected by:

- press fittings;

- compression fittings

To perform these works, a pipe cutter, a chamfering tool (for removing plastic to a layer of aluminum foil), a pipe bender, a press tool and pliers (for mounting press fittings) are required. Accordingly, skills are required to work with these devices.

B. Steel pipes

They are interconnected by either a threaded connection (couplings, angles, tees are used), or by welding. In the first case, skills are required to seal a threaded connection, in the second - experience with a gas burner. If you have never held it in your hands, definitely, this option is not for you.

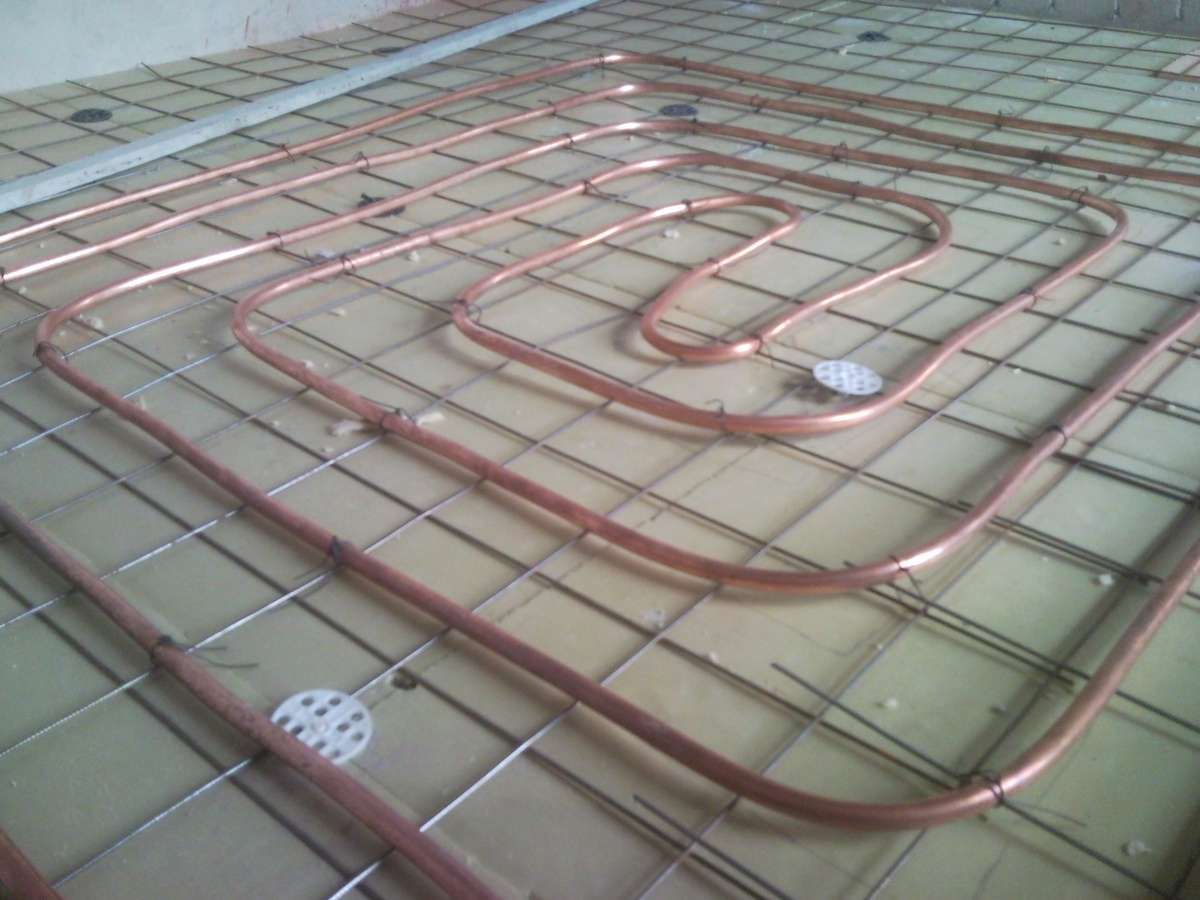

Concealed pipe wiring

This option involves shredding walls for laying pipes in them. Work of great skill does not require, but a powerful (at least one kilowatt) angle grinder ("Bulgarian») And cutting wheels for concrete or brick depending on the type of wall.

Work sequence

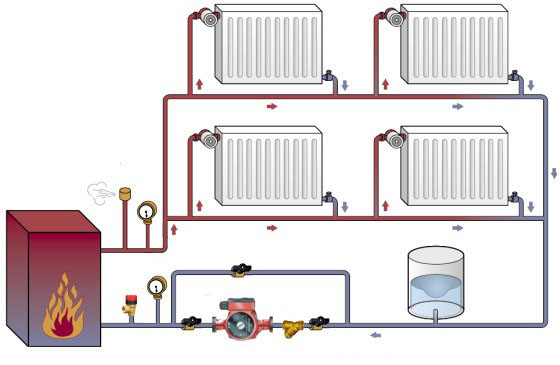

The success of any work is at least half dependent on a clear plan for its implementation. And do-it-yourself water heating is no exception. Regarding the independent creation of heating, the sequence of work is as follows:

- System design. It is necessary to choose the optimal scheme taking into account preferences, capabilities and objective conditions. It is possible that at this stage it will be decided to leave some elements of the old system, for example, heating radiators. Of course, it will be difficult for an amateur to perform thermal and hydraulic calculations, but there are empirical formulas by which it is possible to calculate the boiler power and the number of radiators quite accurately based on their type.

- Obtaining permits in state bodies for the installation of the heating system (in case of its autonomous option).

- Acquisition the necessary component parts for the new system.

- Dismantling elements old system water heating.

- Boiler installation.

- Installation of the expansion tank and circulation pump (if they are not included in the boiler package).

- Installation of radiators.

- Piping the boiler and radiators with pipesinstalling the necessary fittings.

- Connecting the boiler to the gas systemin case of installation gas boiler (performed by gas industry specialists).

- Commissioning works.

Do-it-yourself water heating. Common mistakes

- The wrong boiler is selected. Usually this happens when the boiler power is selected right up to the bottom, without taking into account a number of factors - the presence of an additional external wall (in corner apartments), lack of thermal insulation (for example, 130-300 W / m is required for a non-insulated house2, and for thermally insulated with modern windows - only up to 70 W / m2), the apartment is on the first or last floor, etc.

To avoid mistakes - make an accurate calculation, taking into account all factors. Detailed information about them can be easily found on the Internet. - Insufficient chimney height. As a result, there is not enough traction, and the boiler automation turns it off.

To avoid mistakes - choose the correct length of the chimney. For a gas boiler, this is at least 4 meters, for the rest - 5 meters (with the exception of a gas boiler with a coaxial chimney). - Use of pipes, not intended for heating systems. For example, put polypropylene pipes PN10, which are designed for either cold water supply (SDR11) or hot (SDR6). And the pipe PN16 or PN20 is necessary.

To avoid mistakes - choose the right pipes, carefully read what they are for. - The use of pipes made of different materials. Firstly, this can lead to the appearance of large internal stresses due to different coefficients of thermal expansion. Secondly, the occurrence of electrochemical reactions (corrosion) at the joints of pipes of different materials. For example, copper and aluminum pipes cannot be connected.

To avoid mistakes - use pipes from one material. - Installation radiatorsnot intended for this system. There are two limitations:

- by permissible pressure in the system (applies to a centralized heating system);

- electrochemical compatibility of materials (of which we spoke above).

To avoid mistakes - choose the right radiators in accordance with the operating conditions.

- Incorrect radiator connection - entanglement of the input and output when connecting shut-off and control valves. This leads to loss of heat transfer from this heater.

How to avoid mistakes - connect correctly radiator in accordance with the instructions. - No emergency drain (relevant for an autonomous heating system).

- At first, this makes repair difficult.

- SecondlyThere are situations when it is necessary to urgently drain the water from the system or lower the pressure. To avoid mistakes - provide emergency drain (and it is better to do it in the sewer system).

The benefits of self-heating water heating

We wrote about the main benefits of a home-made heating system at the very beginning:

- saving personal funds;

- you do for yourself, so you do it in good conscience.

But there is one more advantage. You perform work at a time convenient for you. And if there is no way to leave the apartment for the duration of the repair, then do-it-yourself water heating is an additional comfort, since there is no outsider factor.