Polycarbonate Fence: 9 Tips for Choosing and Installing

Each owner of a suburban or summer cottage site sooner or later faces the need to install fences around its territory. This is due both to the desire to protect property, and to make the situation more secluded, that is, to hide personal life from the intrusive views of passers-by. Fortunately, at the moment the choice of materials suitable for arranging the fence is more than wide. It all depends on your financial capabilities, personal preferences and the purpose of the fence. Many people prefer natural materials to synthetic, even despite their high cost and some disadvantages. However, more and more you can see the graceful and seemingly weightless polycarbonate fences. In this article we will consider the main advantages and disadvantages of this modern material, its varieties and cost, as well as give some practical tips regarding the choice and self-installation of polycarbonate fences.

1. About polycarbonate and its varieties

Although polycarbonate as an installation material appeared on the Russian market more than 20 years ago, it has received widespread use only recently. Initially, it was used as an alternative to glass due to the higher strength of polycarbonate crystals, lower weight and operational safety. Then arbors began to appear and canopies with roof made of polycarbonate sheets, greenhouses and other small structures. And only recently, the material began to be actively used in the construction and construction different kinds the fence. Polycarbonate is a polymeric material, a type of plastic, which is available in the form of sheets.  Depending on the structure of the sheet, the material is divided into two types:

Depending on the structure of the sheet, the material is divided into two types:

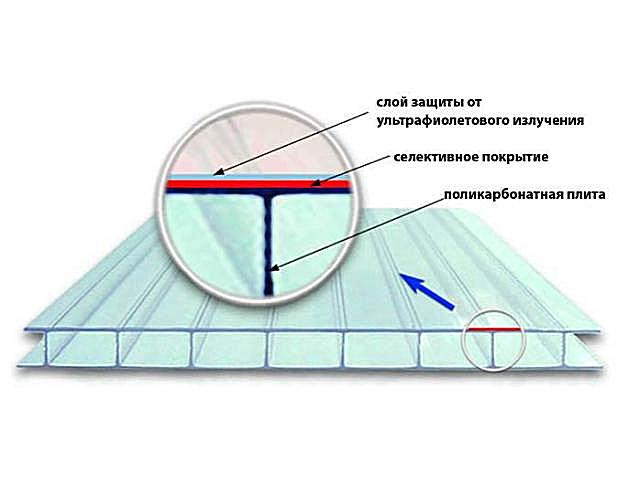

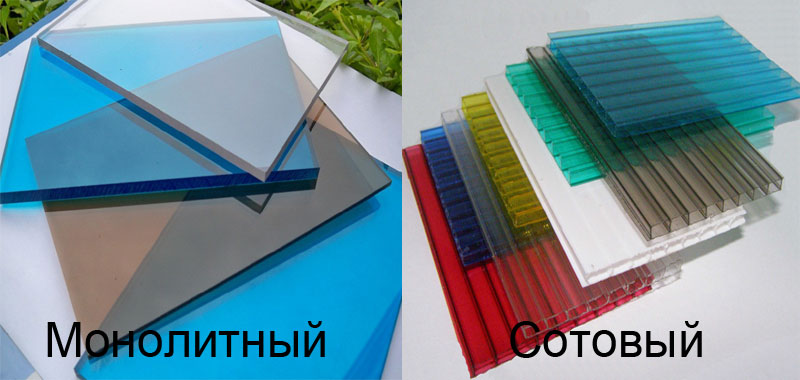

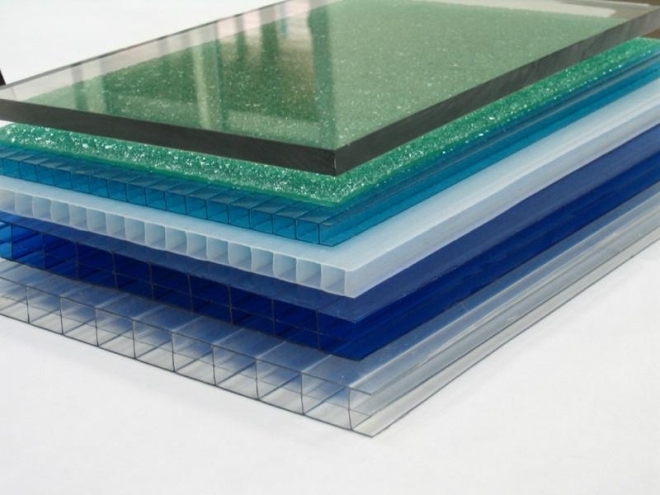

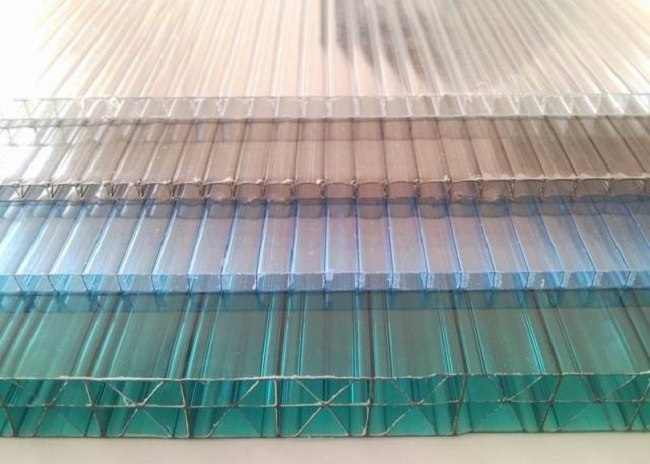

- Cellular or cell - It is made from plastic granules by extrusion. In this case, the sheet has a cellular structure. If you look at a section of a sheet, you can clearly see that it seems to consist of two planes, between which vertical jumpers are located along the entire length. It is they who form the shape of the cells. Depending on the thickness of the sheet, the cells may have additional zigzag bridges, which significantly increases the strength of the material. The thickness of the cellular polycarbonate lies in the range of 4-32 mm;

- Monolithic - known to all, but under a different name - plexiglass. However, the similarity is only in appearance and mechanical properties. But the chemical composition is completely different. Monolithic polycarbonate, unlike cellular, is completely transparent and can have a thickness of 4 to 32 mm. Weight, strength indicators and, accordingly, the cost of such material significantly exceed the cellular option.

Based on the characteristics of both varieties of polycarbonate, it can be argued that for the arrangement of fences most suitable would be a cell material. A monolithic will be a suitable option for special types of glazing, where you need to cover a large area and make the structure windproof and safe.

2. Advantages and disadvantages of the material

Like any material, this polymer has both a host of advantages and some disadvantages, having become familiar with it, it will be easier for you to understand whether this material will really be the best option for your particular needs. ABOUT the benefits honeycomb material:

- First of all, I want to note weight material that can safely be called insignificant. This will not only make transportation and subsequent movement of sheets around the site simple and affordable, but also affect the fence itself. In fact, such a fence can be called lightweight. Of course, the weight of the supporting posts and lintels must be taken into account, however, in comparison with concrete or forged products, the advantages are obvious. Accordingly, you can do simpler type of foundation, which entails a certain cost savings;

- Next, I would like to draw attention to the fact that the material is translucent. For some, this fact plays absolutely no role, but for experienced gardeners or agronomists it can become decisive. Sheets pass 80-85% of sunlight. In this case, there are varieties with a special film on the front side, which will protect plants from ultraviolet radiation. And most importantly - despite the light transmission, the picture behind the fence will be blurry and blurry, which will allow to hide what is happening on the site from strangers;

- Cellular polycarbonate is also great sound insulator. A high fence of such sheets will absorb noise and sounds from nearby roads or noisy places. This is possible due to the air gap in the cavity of the cells;

- From an aesthetic point of view, this polymer is of particular interest. In addition to the fact that in itself it looks neat and pretty enough, it can also be bent as necessary. To do this, of course, you must carefully and surely take into account the maximum bending angle for a certain thickness of the sheet. Also, flexibility is maintained only in one plane parallel to the internal partitions;

- In addition, quite accessible to consumers many colors as well as the ability to select the degree of light transmission of the sheet and the shape of the inner cells. All this allows you to build quite interesting and beautiful hedges;

- Ease of processing. Sheets are quite easy to cut using a conventional jigsaw and a suitable saw blade. This provides both simplicity and speed of mounting sheets on the frame;

- Material not subject to formation mold, fungus and other microorganisms that can damage the structure. The polymer is not susceptible to corrosion. Given that polycarbonate is not susceptible to external harmful factors, its service life is superior to wood and metal structures;

- The range of operating temperatures is from -40 ° C to + 120 ° C. The material withstands the effects of severe frosts, strong gusts of wind (subject to all installation rules), exposure to hail and snow. Due to the presence of a protective film with ultraviolet filters, the color fastness is maintained for a rather long time;

- After installation, the material practically does not need special care. It does not need to be painted, coated with protective compounds. It is enough to simply clean the surface from contamination;

- Material is fireproof. It begins to melt at temperatures above 100 ° C.

Concerning disadvantages:

- ABOUT strength material - monolithic polycarbonate is much stronger than cellular and can even withstand a shot at point blank range. Cellular in this regard loses. It is more fragile. If you throw a stone into the fence, a hole, of course, does not form, but cracking and chipping of the upper layer are practically guaranteed. Therefore, this is not the best solution if vandalism is widespread in your summer house cooperative or residential sector. Also, over time, small scratches will form on the surface of the plastic, due to which it will lose its aesthetics and become cloudy;

- If some installation features are not observed, namely, the need to seal the upper and lower ends of the sheet, dust and small particles will accumulate inside the cells over time. In the cold season, condensation is inevitable, which in combination with dirt inside the sheet will create an unpleasant picture;

- You should be careful when choosing polycarbonate domestic producers. Not all, but most of them do not provide the proper quality of the material. As a result, there is an increased fragility and the possibility of cracking under the influence of low temperatures;

- But the cost of imported material is not always low. Given the presence of UV protection, the need to purchase additional fasteners and curly cuts, the final cost of such a fence can be equal, and sometimes even exceed the cost of a wooden or metal fence;

- Polycarbonate also has a high sailing. And if you do not provide a reliable frame, the sheets can simply be torn off by gusts of strong wind;

- Be sure to consider linear coefficient expansion during the construction of the frame and drilling holes for fasteners. On average, dimensions increase by 1 cm per meter / by 20 ° C both in width and in height. If you neglect this, the sheet can simply lead, because of which it will crack.

3. What polycarbonate is suitable for the fence?

We already mentioned that it is better to use cellular polycarbonate for fences. Now necessary decide with his thickness:

- Of course, the thicker the stronger the sheet and the better soundproofing properties of the finished structure. However, when choosing a thickness, you need to reason rationally. First of all, you need to consider which object will protect the fence. If this is a residential building where you are constantly located, then it really makes sense to spend money on thicker material. If it is a summer cottage or a country house of rest, where you visit only on weekends and the fence function is only the delimitation of the site, you can consider finer material;

- For summer cottages, sheets with a thickness of 4 or 6 mm can be used, sheets from a thickness of 8 mm will be more durable;

- It is also worth considering the size of the sheet in the section. After all, this material is attached between certain types of supports. The greater the distance between the supports, the thicker you need to use the material.

Now need decide from color:

- Optimal The option is bronze or silver, which go well with other materials used in the construction of the fence. For example, a metal fence with forging elements looks very noble in combination with bronze sheets. Especially if the protective coating of the metal has a similar shade;

- If there is pool, you can choose blue or blue or shades. Thus, you emphasize the presence of this element, and the fence itself will look harmonious;

- If there is a lot of greenery in the territory, it is reasonable to give preference to a green shade. The fence will not attract attention and simply dissolve on the background of plantings;

- Neutral is transparent and milky honeycomb polycarbonate, it blends perfectly with the support columns of white brick or natural stone;

- You can choose a red tint if you really like this color, and it resonates with other elements. For example, with the color of the roof of the house or gazebo.

4. Types of polycarbonate fences

This lightweight and modern material blends perfectly with many other materials. Combining it in various versions, you can not only achieve an aesthetic design with high decorative properties, but also save on the amount of more expensive materials. The most common types of polycarbonate fences:

- Sectional construction from profile pipes on a metal frame and steel corners. In this design, the sheets of material are a determining factor in choosing the size of the span.Sections have the same size and can be attached to both metal and stone columns;

- Stacked Fences have no restrictions in either shape or size. Moreover, the shape of the section may have the most unimaginable outlines;

- On the brick or stone base. It is clear that polycarbonate will in any case be mounted on a frame. But the frame itself can be attached to the stone base and stone columns. Such a fence combines reliability and decorativeness;

- Forged polycarbonate fence looks very impressive and attractive. The idea is that fragments of polycarbonate are mounted from the inside and thereby hide the territory, and decorative forged elements remain visible from the outside.

The last and penultimate option is the most aesthetic and one of the most popular. In addition, a combination with stone or forging significantly increases the life of the entire structure. The simplest will be a welded fence made of metal sections with polycarbonate and metal posts.

5. An approximate calculation of the required amount of material

Before purchasing material, it is necessary to make an approximate, and better accurate calculation of the required amount of material. Especially if you decide to carry out the installation yourself and ask for help or return the remains of unused sheets there is nowhere.  To do this, you need to know the exact length of the fence, know the size of the gate and entrance gate, if any. Approximate calculation:

To do this, you need to know the exact length of the fence, know the size of the gate and entrance gate, if any. Approximate calculation:

- Take a plot with a standard area of 6 acres, that is, 600 square meters;

- The size of the plot will be 20 × 30 meters. There will be a gate for entering a car 3 meters wide and an entrance gate 1 meter wide;

- Let's say the span between sections will be 3 meters, and the fence height will be 2 meters;

- We consider the length of the fence - (20 + 30) × 2 = 100 meters. Subtract the width of the gate and the gate, we get 100-1-3 = 96 meters;

- We calculate the required number of supporting columns, taking into account the span between the sections - 96/3 = 32 pcs;

- If you buy pipes with the expectation of subsequent independent cutting, and not finished columns of a certain height, then you need to calculate the required length. To do this, the number of columns must be multiplied by the desired height of the fence - 32 × 2 = 64 meters of the pipe. But do not forget that the pipe should be buried in the ground to a depth of about 1 meter. Therefore, correctly perform the calculation in this way - 32 × 3 = 96 meters;

- Now let's calculate the number of lags. For one span, 2 lags are needed - upper and lower - 32 × 2 = 64 pcs;

- The required number of fasteners for logs is also calculated - 64 × 2 = 128 pcs;

- For fastening one log you need 10 screws, which means that in total we need 64 × 10 = 640 screws;

- Now you need to calculate the required amount armature for the frame. For example, for each span there will be 4 transverse crossbars from ribbed reinforcement. Then you need 32 × 4 = 128 meters;

- Now let's determine the size of the sheet. Let the polycarbonate itself have a height of 1.5 meters, the width of the support posts will be 100 cm, the indent on both sides from the end of the polycarbonate to the posts will be 5 cm. Then the total area of the polycarbonate will be 32 × 1.5 × (3-0.1- ( 0.05 * 2)) = 134.4 sq. meter. The area of one sheet is 134.4 / 32 = 4.2 sq.m. Accordingly, the size of the sheet is 4.2 / 1.5 = 2.8.

- So, we need 32 sheets 1.5 * 2.8 meters in size;

- Do not forget to calculate the amount of reinforcement that will be required to reinforce the foundation. For the frame, you need 4 rows of reinforcement, which means the length of the fence is 96 × 4 = 384 meters. Plus a 10% margin, totaling 422.4 meters.

6. Site preparation process

After you have decided on the purchase of the necessary materials, you need to prepare a site for future installation.

- Any work on the ground always starts with markup. Making it on the ground is always more convenient with the help of wooden posts and rope. First, pegs are set around the perimeter of the rectangle, then the remaining points are added - the beginning and end of the gate and the gate. Then the rope is pulled.Now you clearly see the boundaries of the future fence;

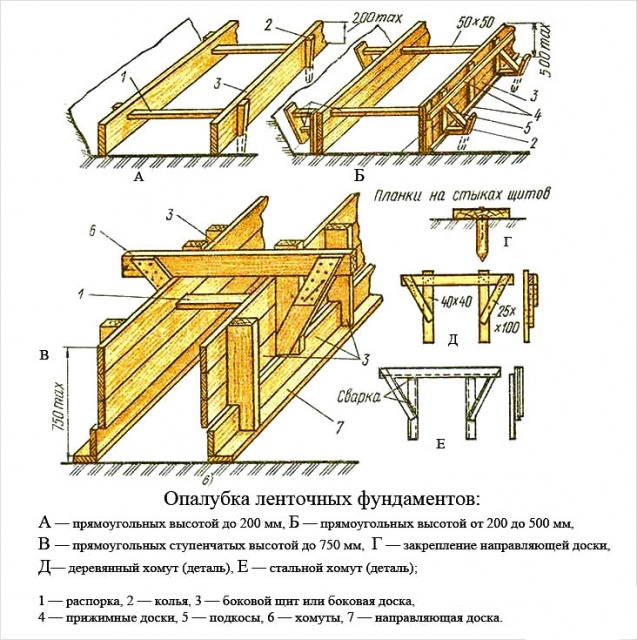

- Focusing on the markup, you need dig a trench around the perimeter under the future foundation. The width of the strip foundation can be 30-40 cm, and the depth is 40-50 cm;

- In addition, you need to dig holes in the places where the support posts are installed, with a depth of at least 100 cm;

- A layer of sand and gravel should be poured into the pits and in the trench to prevent stagnation of water under the foundation;

- Now you can start building formwork which should hold the concrete mixture when pouring. The formwork is knocked down from wooden boards, whose height must exceed the desired height of the future foundation by at least 5 cm;

- After the formwork is ready, reinforcement is performed. Experts recommend installing a reinforced frame so that it does not touch the bottom or walls of the trench;

- After that, you need to install the support posts. In this case, you will need help, because the posts should be perfectly upright. The easiest way is to ideally evenly install the first pole and the last, then pull the rope between them and lean on it.

7. Concreting of pillars and foundation

Self-assembly of the fence often involves independent mixing of concrete. Rented for these purposes concrete mixer, stocked up with cement, sand, water, gravel and someone else's help. It is not recommended to knead immediately a large amount of the solution until you get the hang of it quickly enough to develop it. Immediately get ready for the fact that the trench is filled need to be completed in one day.  So you can avoid the formation of expansion joints and various irregularities.

So you can avoid the formation of expansion joints and various irregularities.

- After concrete mixing, the mixture from the concrete mixer is poured into buckets, and then into the trench;

- Concrete must be laid in such a way that voids do not form;

- After the foundation is flooded, it is necessary to expel air from it and align the common plane;

- If you work on a hot day (which is not recommended), be sure to cover the concrete with plastic wrap and periodically spray it to prevent cracking;

- Concrete will harden for a long time, after 10-15 days it will gain only 50% of its strength. At this time, formwork can be removed;

- Full hardening of the composition will occur only after 30 days.

8. Assembly of the frame

During this time, you will just have plenty of time to assemble the frame. But you should be amazed by the idea that the most labor-intensive and difficult stage of work is already behind.

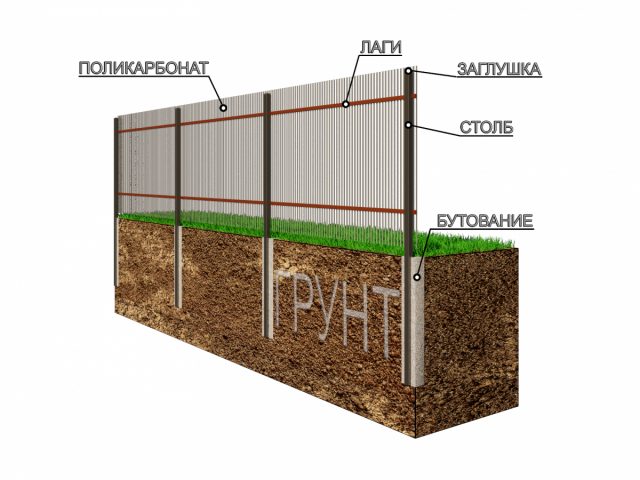

- We will fasten the polycarbonate sheets to the transverse logs, which in turn will be attached to the support posts;

- This means that the lags must be welded to the posts;

- At this stage very important make sure that all the lags are on the same line, and observe their horizontal. From a practical point of view, little depends on this, but the flaws will greatly affect the appearance of the structure;

- To facilitate the work on each column, you need to markup, or pull the rope from the first column to the last;

- Typically, the lags are made of steel corners, thick reinforcement or shaped pipes;

- After welding, your scale will remain on the surface, which must be removed;

- Welding places are most susceptible to corrosion, so they must be coated with paint or other protective compound;

- As a result, you should get something similar not this:

9. Installation of polycarbonate sheets

Only a little remained - to fix the polycarbonate sheets on the frame. However, when working with this material you need to be careful and consider features his buildings:

- First, the sheets are cut into fragments of the right size;

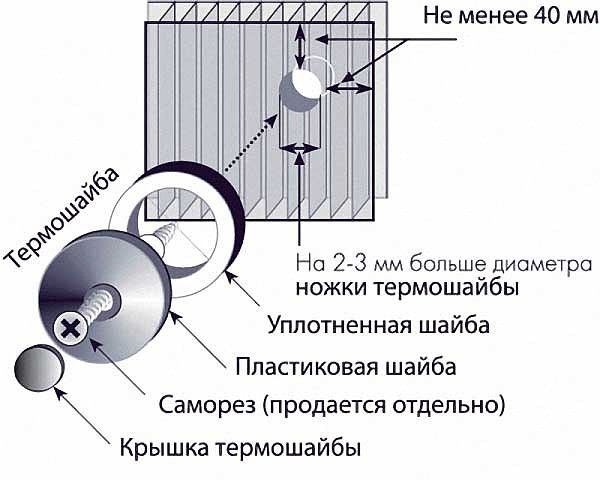

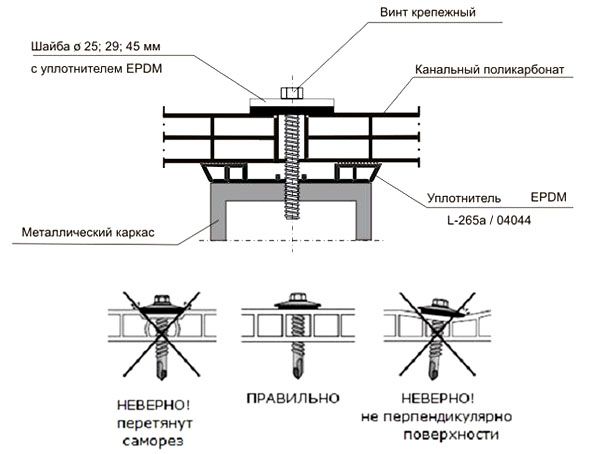

- After that, holes are drilled at the attachment points. Take into account the linear expansion of the material and make holes with a diameter of 2-3 mm larger than the thickness of the thermal washer;

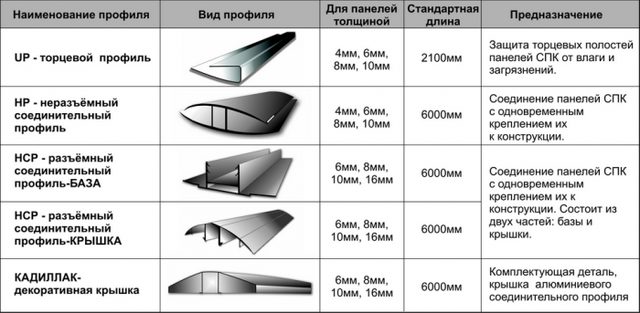

- It is at this stage that it is most convenient to seal the upper and lower ends of the sheet to avoid accumulation of dust and debris inside;

- For this, special stubs are used:

- After this, the sheet with the help of special fasteners is screwed to the lags;

- How to spin fasteners are shown in the figure:

That's all, you got acquainted with the most primitive type of polycarbonate fence, however, based on these recommendations, you can create any design to your taste. And the most important thing - polycarbonate cost a cellular thickness of 4 mm is from 120 rubles per square meter, and 10 centimeters from 300 rubles.