7 tips for choosing and installing a tide for a base

The basement is an integral part of the building, located between the load-bearing walls and the upper edge foundations. Often the base is the upper part of the foundation, protruding above the surface of the soil. It is necessary for thermal insulation and waterproofing of buildings, because it raises the building above moist and cold soil.

Running base from concrete, bricks, rubble stone, blocks - all these materials have a large number of micropores. The basement of the building is constantly exposed to atmospheric influences, especially in the cold season. During periods of thaws, moisture from rain and snow is absorbed into the pores of the structural materials, and upon the onset of negative temperatures, the water, expanding upon freezing, gradually destroys the base. That is why it is necessary to take seriously the issue of preventing the basement from getting wet. The solution to this problem in some cases is to install ebbs. Let's figure out how to choose and set the tide for the base.

Running base from concrete, bricks, rubble stone, blocks - all these materials have a large number of micropores. The basement of the building is constantly exposed to atmospheric influences, especially in the cold season. During periods of thaws, moisture from rain and snow is absorbed into the pores of the structural materials, and upon the onset of negative temperatures, the water, expanding upon freezing, gradually destroys the base. That is why it is necessary to take seriously the issue of preventing the basement from getting wet. The solution to this problem in some cases is to install ebbs. Let's figure out how to choose and set the tide for the base.

Low Tide Design Elements

In the prevailing embodiments, the tide consists of three elements

In the prevailing embodiments, the tide consists of three elements

- Fixing gate - serves to fix the product using various hardware to the wall or facade profiles

- Shelf - it can be from 5 to 40 cm wide. It is used to facilitate the outflow of water, it is arranged at an angle of 100..110 degrees with respect to the wall.

- Dropper - prevents moisture from getting under the tide, additionally serves as a stiffener.

Whether or not a base tide is needed

Before acquiring low tides, it is necessary to determine the design features of the building. The need for their installation depends on this.

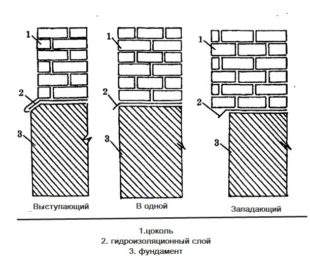

Base types:

Base types:

- The dropping down. The basement of the building is thinner than the wall, due to this a peculiar canopy is formed. In the case when, after the final cladding, the ledge is greater than or equal to 5 cm, additional waterproofing of the surfaces from atmospheric influences and the casting device is not required. Moisture flowing from the walls does not reach the basement in sufficient quantities for negative processes.

- In the same plane with the wall. If, after facing, the base and the wall are in the same plane, the installation of ebbs is not necessary, but in this case plinth cladding material must be insulating. Natural stone, ceramics or special finishing mixtures with calculated properties are well suited. Additional measures are smear insulationmade with solutions based on bitumen or acrylic resins.

- Protruding base. The most common option. It is often a consequence of the arrangement of basements and basements. The enclosing structures of such rooms should be thick enough to absorb loads from the building and provide reliable thermal insulation. A large amount of water accumulates on the ledge of the base. In order to prevent moisture saturation, the installation of ebbs is mandatory.

Ebb material

Depending on the material from which the tide is made, the shape, scope and installation method are significantly different. They can be purchased at hardware stores or made and assembled with your own hands. Consider their range in more detail to understand the advantages and disadvantages of possible options.

According to the material, ebbs are divided into:

- plastic;

- steel;

- aluminum and copper;

- concrete;

- clinker;

- wooden.

Plastic ebbs distributed due to low cost. On sale there is a huge variety of colors and textures. This will be the best choice for buildings covered with vinyl panels (siding in use). TO the benefits also include durability, noiselessness, low weight, ease of installation. Disadvantages fragility, especially in the cold season, discoloration and aging of the material under the influence of sunlight, poor maintainability.

Plastic ebbs distributed due to low cost. On sale there is a huge variety of colors and textures. This will be the best choice for buildings covered with vinyl panels (siding in use). TO the benefits also include durability, noiselessness, low weight, ease of installation. Disadvantages fragility, especially in the cold season, discoloration and aging of the material under the influence of sunlight, poor maintainability.

Steel ebbs can be galvanized, polymer coated and painted. They look much better than plastic and will be in perfect harmony with most wall covering materials. The color scheme duplicates the roofing ebbs, skillful selection can make your home look thoughtful and complete.

TO pluses applies:

TO pluses applies:

- long term of operation;

- strength;

- availability;

- ease of installation;

- low price;

- aesthetics;

- weather resistance.

Of cons:

- noisiness

- the appearance of rust spots in the places of cuts.

Both the first and second minus are easily eliminated with proper installation. Cut edges are treated with alkyd varnish or paint in color, and in order to avoid noise, the basement slope is formed from polyurethane foam and open with mastic.

Steel castings universal they can be combined with almost any material, exceptions may be PVC facades.

Aluminum and copper base castings have all the advantages of steel products, except for the price. The price, especially for copper counterparts, is quite high, in addition, you should be wary of vandals hunting non-ferrous metals.

Aluminum and copper base castings have all the advantages of steel products, except for the price. The price, especially for copper counterparts, is quite high, in addition, you should be wary of vandals hunting non-ferrous metals.

High-quality castings made of copper and alloys will add a noble, ancient look to your home. They are well suited to rubble and decorative stone, aged masonry.

Concrete ebbs will harmoniously look on reinforced concrete stone buildings and structures. They have a lot of weight, which should be taken into account when installing the foundation. Planks with a length of 3.9 to 6 m are sold. They are made of concrete mix M 450, which has high strength characteristics. It is poured in special silicone molds, if you wish, it is possible to order an individual configuration and color, or make it yourself.

Concrete ebbs will harmoniously look on reinforced concrete stone buildings and structures. They have a lot of weight, which should be taken into account when installing the foundation. Planks with a length of 3.9 to 6 m are sold. They are made of concrete mix M 450, which has high strength characteristics. It is poured in special silicone molds, if you wish, it is possible to order an individual configuration and color, or make it yourself.

The advantages include:

- almost unlimited service life;

- strength;

- the possibility of an individual order;

- weather resistance.

Of cons:

- significant weight requiring reinforcement of the foundation;

- inconvenience during installation.

Clinker slats will be in harmony with ceramic tiles, artificial and natural stone and any kind of brick. This is one of the most expensive types of base ebbs, requiring considerable skill and skill for their installation. When installing with your own hands, you can significantly spoil the appearance of the products, chop or thoroughly stain the matte clinker surface with building mixtures.

Clinker slats will be in harmony with ceramic tiles, artificial and natural stone and any kind of brick. This is one of the most expensive types of base ebbs, requiring considerable skill and skill for their installation. When installing with your own hands, you can significantly spoil the appearance of the products, chop or thoroughly stain the matte clinker surface with building mixtures.

The benefits include:

- long term of operation;

- significant strength;

- aesthetics;

- weather resistance.

TO disadvantages:

- significant price;

- increased requirements for the accuracy of installation work.

Wooden ebbs. Such protective strips should be installed on wooden housesto preserve the natural look. It is better to purchase varieties of wood with high moisture resistance, for example, larch. Impregnate before installation antiseptic compounds. After installation, the product should be treated with mineral oils or alkyd varnish. This material has more minuses than pluses, it is susceptible to decay, can dry out with the formation of through cracks, parasites appear in the structure quite often, and require constant care during operation. Perhaps the only pluses are the low price and the possibility of self-production.It is worth acquiring this type of ebb only to give the house an ethnic look.

How to choose a size

To select the required size of the ebb platform, it is necessary to measure the protrusion of the base and add 3 ... 5 cm to the result. This stock is necessary for the formation of an overhang, which will prevent water from entering the horizontal surface. Round the result and select the most similar value from the standard ones. You need to measure the base with the final cladding or to know what thickness it will be in order to plan the stock.

How to calculate the required number of tides

To calculate the amount of material for installation it is necessary:

To calculate the amount of material for installation it is necessary:

- Select product material

- Ask in advance how long the slats can be purchased from your chosen seller, find out about the availability of ready-made corner and connecting elements.

- Measure the perimeter of the building with a protruding base, where it is planned to install tides. Divide the result by the length of one bar and multiply by the safety factor. For ceramic, stone and concrete products, it is 1.02, for metal and plastic without connecting and corner elements - 1.1.

How to install base ebbs on your own

To save money, you can do the installation work with your own hands, but you should approach this event responsibly and painstakingly. There are basic conditions that must be observed when preparing and conducting work:

To save money, you can do the installation work with your own hands, but you should approach this event responsibly and painstakingly. There are basic conditions that must be observed when preparing and conducting work:

- Before mounting, the base must be completely ready, the lining is completed, the integrity of the waterproofing is checked, if necessary restored, slopes are formed at an angle of 15..20 degrees.

- The ebbs should be fixed firmly to avoid fluctuations due to wind load. Particular attention should be paid to the corner sections and the places where the parts join together.

- For metallic tides, it is necessary to form a foam backing to reduce noise.

- When installing steel strips with coatings, it is necessary to monitor its integrity, to avoid the appearance of chips and scratches, and if they appear after installation, treat with varnish or paint in color. For a better appearance, it is better to buy a coating in the spray can.

- The interface between the elements of sheet castings must additionally be treated with silicone or polyurethane sealant for outdoor work.

- Depending on the type of base casting you have chosen, select a tool, purchase fasteners, hardware for metal modifications and cement mixes for clinker and concrete slats.

How and from what you can make ebbs yourself

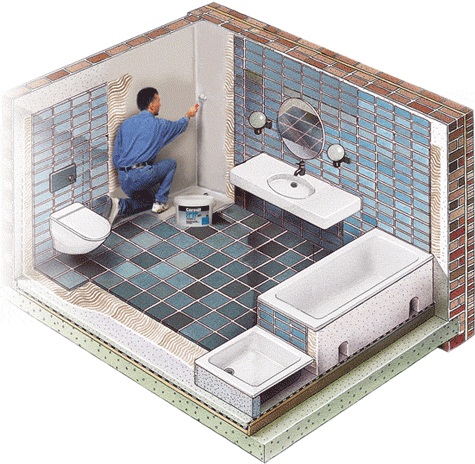

If necessary, you can make ebbs at home from the simplest materials. This will add personality to your building and save money. Most often, craftsmen make their products from sheet metal or ceramic tiles for outdoor work.

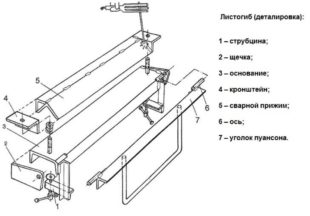

To make metal base tides you will need:

To make metal base tides you will need:

- Roulette;

- Scriber or marker;

- Plumbing square;

- Corner grinder or electric shears for metal, a reciprocating saw is also suitable. Cutting long strips with hand scissors is extremely inconvenient, this can lead to bending of the material, which will ruin the appearance of the final product;

- The most primitive machine of a tinsmith, the Internet is full of diagrams and detailed drawings of its device, manufacturing will not take much time and effort, but will make the tides high-quality and beautiful. It is not worth bending a steel product even a meter long without such a device, the result will be very far from perfect.

Scope of work:

Scope of work:

- Determine the desired width of the shelf of the product, add to it the dimensions of the shelf and drip with a bend, add an allowance for bending - 1 cm;

- Mark prepared sheet material and cut into strips;

- Bend with a machine.

For the device of ebbs made of ceramic tiles, it is better to combine production with installation.This will allow you to significantly reduce and simplify processes. First of all, you need to choose a tile for outdoor work, the best choice is clinker. Then choose a mixture suitable for this material. Since overhangs due to fragility do not make more than 2 cm, in order to provide reliable protection, the base is made entirely of tiles. In the future, the scope of work is no different from facing the walls with ceramic tiles.